| | #916 | |

| BHPian Join Date: Sep 2009 Location: Trivandrum

Posts: 932

Thanked: 1,218 Times

| Quote:

Regards Adrian Last edited by adrian : 29th November 2010 at 13:29. | |

| |  ()

Thanks ()

Thanks

|

| |

| | #917 | |

| BHPian Join Date: Oct 2010 Location: Pune

Posts: 52

Thanked: 0 Times

| Quote:

??? ???Thanks Adrian...i will get the oil level topped up. | |

| |  ()

Thanks ()

Thanks

|

| | #918 |

| Senior - BHPian Join Date: Oct 2007 Location: Brighton

Posts: 1,193

Thanked: 355 Times

| @Codded-At what speeds you are facing the instability? Sometimes you can feel the bike going all softy at slow speeds around the bend and thats when your base shift sides. I am talking about he springs on the seat which twist and compresses sideways while turning and we feel the whole biking is twisting around the corner. There are three things you will have to check and I am quite positive that your instability problem will be resolved for good. Do check if your rear tyre is not damaged. Check for the rear rim run out and also the rear tyre for the same. I have seen couple of new but damaged tyre whose run out was enough to cause instability. There are two reasons for the cause. 1. If you have run the tyre with quite low pressure which damages the sidewall and distort the tyre. 2. Manufacturing defect. Take the chain off and then rotate the rear wheel to see if the squeak is from the chain or break shoes/ bearings. Front shocks shouldn't squeak even if it has less oil, either the fork sleeves are touching or something else. Front wheel not rotating freely is what I have observed on few RE bikes. Its to do with too much runout of the front disc and also when new the front pads have less clearance between the disc. After it wears out a bit, it should rotate more freely. Get the pads removed and use sand paper to smooth the pads out a bit. Also lubricate the calliper pins. Use a drop of brake fluid over the pads and squeak should go away. Pads do make some noise when running too dry or some sand gets into them. The noise from the tappets will take some time to settle down, just don't worry about the valve terrain. Once you cross 5k, all will be smooth. Regarding the EFI details, Naren has done a wonderful job of putting the info together. TE- Is the engine temperature sensor. PM- Is the MAP sensor. TH- Is the throttle position sensor K-line- Is the connector used for connecting the ECU to computer or code reader. 1-G- Is ground. FLPR- Is the fuel line pressure regulator which controls your the amount of fuel injector gets. We don't have a nocking sensor on our C5. Regarding the oil level, please check oil once engine warmed up and put it on the Centre stand. Rev once and switch off the engine. Now if the oil level is in the middle of the max and min level indicator then leave it if less then the middle only then add a bit(ONLY LITTLE) C5 can work flawlessly even if there is only a litre left in the sump. But you cross the limit and overfill it then there are consequences. I never had my engine consuming oil so I doubt it is the case with you. If you want to convert it to carburettor then yes it is possible without having a nervous brake down. Simply swap the wiring from Classic 350 along with the ignition module and magneto + carburettor (off a 500) and you are good to go. I will be compiling a list of parts you would need and cost involved for the setup. Just need to find some spare time. How to use the test wire for reading codes Use a piece of wire to the test pin connector and ground it(-ve). Then read the blinks to relate it to faulty sensor. MIL will glow continuous. Engine will start but not perform to its potential. LONG 0 SHORT 6 --- Throttle Position Sensor (TPS) circuit malfunctioning LONG 0 SHORT 9 malfunctioning--- Manifold Absolute Pressure (MAP) circuit LONG 1 SHORT 1--- Engine oil Temperature (TE) circuit malfunctioning MIL will glow continuous. Engine will NOT Start but will crank. LONG 1 SHORT 5--- Rollover Sensor circuit malfunctioning LONG 3 SHORT 3--- Injector circuit malfunctioning LONG 3 SHORT 7--- Ignition Coil circuit malfunctioning LONG 4 SHORT 1--- Fuel Pump circuit malfunctioning LONG 6 SHORT 6--- Crankshaft position circuit malfunctioning Last edited by Randhawa : 29th November 2010 at 23:07. |

| |  ()

Thanks ()

Thanks

|

| | #919 |

| Senior - BHPian Join Date: Dec 2009 Location: Bangalore

Posts: 1,343

Thanked: 3,168 Times

Infractions: 0/1 (5) | Hey guys, Logging in after a while, and glad to see the thread alive and kicking. Got a lot of info to catch-up on. Had gone on a ride to goa a couple of week back. Then to home town. Covered about 1800 kms of various types of roads to no roads. The bike performed well without any trouble, except a broken speedo cable towards the end of the journey. Did the ride with the goldie on.  Most of the time it was raining, so the bike started squeaking from various places after the ride. Most of the time it was raining, so the bike started squeaking from various places after the ride. Checked the average one, full tank to full tank, and was surprised to get 37 kmpl, with goldie and K&N on. Not sure whether to be happy or sad. The riding was mostly highway and speed between 70-90 during this period. Spent the major part of yesterday at the RE Brandstore service center fixing some of the issues arising after the goa ride. Replaced the speedo cable which had a broken worm. ( bad part quality, speedo cables are generally suppose to last longer than 7500kms) There was squeaking sound when the rear shocks were pressed. The issue was identified as the noise coming from the swing-arm joinery. On opening the swing-arm, we found NO lubrication. Lubricated the hole and the bush with white grease, and fixed the swing-arm back. The squeaking sound is gone. A Shocking discovery: to open the swing-arm, the rear wheel has to be removed. When the wheel was removed and the rear brake pads were being inspected, the mechanic noticed that brake pad springs were touching the inner wall of the Hub. There was a circular mark through out leftover by the spring touching the wall while moving. They asked me if there has been any squeaking sound from the rear wheel, i said i never heard any. They took the hub to a nearby lathe workshop and removed some material from inside, to have enough clearance to avoid interference. The way they went about this whole process seemed like they had seen this issue on the other bikes as well, and knew exactly how to mend it. Another blunder from RE. Shame!! Anyways, i think the spring rubbing against the hub-wall was causing some friction and interfering with the performance (like a minor brake applied all the time). after the lather operation, the bike seems to pull a bit faster. Got the horn fixed, the problem was tuning of the horn had gone bad. Opened the front disc brake assembly myself, and removed the pads. cleaned and sanded them and fixed it back. The squeaking disc noise os gone. HERE, i want to one thing. The front disc brake unit is got a rubber cap kind of thing with grease inside. In mycase, there grease is almost over. What is that part and its use? any ideas? Cleaned and lubricated the centre stand and the side stand, and now they rotate like butter. Earlier it required some effort. Got the chain cleaned and tightened. Have removed the Goldie, and fitted back the upswept. Have tightened the upswept very nicely to avoid any leaks from the joint. Will remove the glasswool and give the goldie for chrome plating. One observation after removing the goldie and fixing the upswept is that jerks have reduced to almost nil. Also the misfire (popping) is reduced drastically. Wonder if the goldie was the cause of the "Jhatkaas"??? Earlier my bike use to jerk at slow speeds as if the fuel was restricted. |

| |  ()

Thanks ()

Thanks

|

| | #920 |

| BHPian Join Date: May 2010 Location: Agra

Posts: 288

Thanked: 34 Times

| Guys take a look at this video (in Spanish) showing complete teardown of the EFI engine..... |

| |  ()

Thanks ()

Thanks

|

| | #921 | |

| BHPian Join Date: Sep 2009 Location: Trivandrum

Posts: 932

Thanked: 1,218 Times

| Quote:

As far as I know the least the resistance exerted on the exhaust gases, the more the power to the engine (Don't know how and also not sure if I am right !). Could any one tell me how the SILENCER is related to MILEAGE and POWER. | |

| |  ()

Thanks ()

Thanks

|

| | #922 |

| Senior - BHPian Join Date: May 2009 Location: Lucknow

Posts: 1,391

Thanked: 18 Times

| Hi The correct relation is between back pressure and torque. You will find better low end torque with a more constricting exhaust path. This might be the reason Nasirkaka's bull was lugging at low speeds. However, I would advise against continuing at very low revs, just downshift if you feel the revs are falling. It will be much better for your engine. Cheers  PS: @Sanjeet I am back in Delhi. |

| |  ()

Thanks ()

Thanks

|

| | #923 |

| BHPian Join Date: May 2010 Location: Dehradun / Bangalore

Posts: 69

Thanked: 19 Times

| @ nasirkaka - The front disk brake calipers are the moving type , meaning that the position of the caliper assembly with respect to the disk is not fixed and the assembly can move , perpendicular to the disk face. This allows any minor run out or non parallel disks to function and also compensates for wear on the pads. The rubber cap covers a rod along which this movement occurs. This needs to be greased when the assembly is opened for cleaning. |

| |  ()

Thanks ()

Thanks

|

| | #924 | |

| BHPian Join Date: Oct 2010 Location: Pune

Posts: 52

Thanked: 0 Times

| Quote:

| |

| |  ()

Thanks ()

Thanks

|

| | #925 |

| BHPian | Simply superb review my friend ...a one well defined and detailed |

| |  ()

Thanks ()

Thanks

|

| | #926 | ||

| Senior - BHPian Join Date: Dec 2009 Location: Bangalore

Posts: 1,343

Thanked: 3,168 Times

Infractions: 0/1 (5) | Quote:

The only knowledge i had was not to press the brake lever when the assembly was out of the disk. On opening the rubber cap, i found minute traces of grease on the metal rod, but as i did not have grease with me, i fitted it back without re-greasing. The reason i opened the disk pad assembly was that since the beginning, my disk had been making squeaking noise. Its SO loud and regular that i do not have to use the horn. The squeaking noise from the disk scares people on road, as it sounds exactly like an old bus. Every service i complain about the noise, they clean the pad, and noise vanished for exactly 2 days. But it is always back to haunt after 2 days. I have tried other methods of cleaning with the compressed air, compressed air with water, but not much help. This time, i opened and removed the pads, cleaned and sanded them with a sandpaper, and installed it back. The bike ran for 2-3 days without any noise, before squeaking again. Now, i am planning to replace the abrasive pads and see if that helps. Is there anyother way out? Some adjustments somewhere? Could it squeak because there is no or very little grease in both the perpendicular metal rods? I am not sure if its the issue with the circular disk as the wheel rotates freely without any sound or hint of friction. Quote:

Sharing a link to some pics of the bike from the recent trip: http://picasaweb.google.com/nasirkak...ngWithTheRain# Last edited by nasirkaka : 2nd December 2010 at 20:49. | ||

| |  ()

Thanks ()

Thanks

|

| |

| | #927 |

| Senior - BHPian Join Date: Oct 2007 Location: Brighton

Posts: 1,193

Thanked: 355 Times

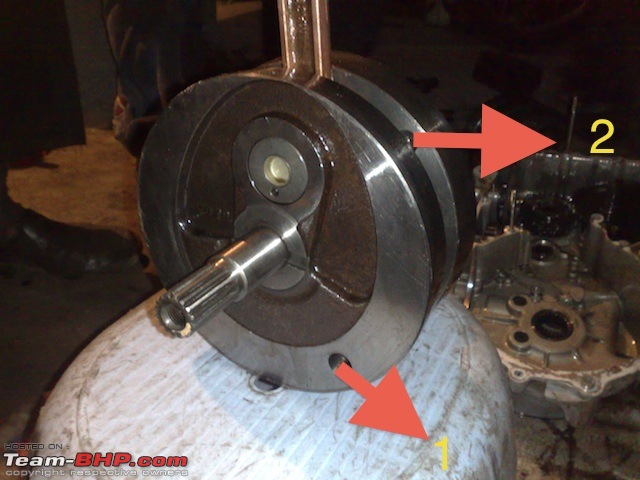

| @Nasir- welcome back  Did you got the air filter cleaned? Did you got the air filter cleaned?@Achint- I will think twice before coming to Delhi now, construction going on all the way till Panipat. barely made it in one piece to Chandigarh last week with almost zero visibility. @cooded-Seriously mate, you need to find a good mechanic around. We could lead you off track with our advice and your problem could be very small to start with. What all I can suggest is to put your bike in centre stand and put in gear to see where exactly the noise is coming from. Meanwhile find a C5 owner who is a bit experienced to help you out. Anyone on here from Pune who can help out a fellow bulleteer please? @epvineesh- Thanks mate. Hitting the rev limiter on C5 and some info on C5 crank A month ago I was revving my bike a bit to see what max speed I can achieve in a gear. Accidentally I hit the rev limiter, I thought it was on second gear but later upon trying again it turned out to be in third gear. I wouldn't advice you all to do that due to the fact that there is a big concern or issues about a said part which has very high risk of failing on the bike so do it on your own risk. I tried it just because my bike was going in for a re-built so took the opportunity to exploit it. Meanwhile during that I have observed something marvellous about C5 engine which makes me love this bike even more. Will disclose it a bit later. Anyways I hit the rev limiter at 50km/h in 1st gear 85km/h in 2nd gear 110km/h in 3rd gear In 4th gear I reached 125 but did not hit the rev limiter and ran out of straight road so left it there. Just loved it when it kept bouncing off the rev limiter  Now for the crank @Bradhey and rest of the gang- When I got the new crank in, I was informed by an RE official that they have increased the weight of the C5 crank by 600gm for less vibrations and mine was the new upgraded one. So before the rebuilt I weighed the old crank and the new one. Turned out the older one was 10.5kg and the new one was only 50gm heavier as supposed to be 600gm heavy. I am on my third crank so there is a possibility that my previous crank was a upgraded one but the new upgraded one came out only few months back so it contradicts the statement. But I am sure it is coming in all new C5 since few months back has the mechanics at RE workshop were telling me that RE has done something(they were not aware of the new heavier crank)in the bike as they felt the new bikes were really smoother then the predecessor. Well my 2nd crank was 10.5kg and the 3rd one is 10.550kg. I tried to make out any physical difference and measured the thickness of the crank weight but couldn't see any. On very detailed comparison between the two crank I found out one difference. There are small holes on the crank weight. As in picture below, there is one hole on booth the crank weight which goes through but there are two more on the left bank of the crank weight which does not go through. You can see them only from middle of the crank. On my previous crank those two holes were drilled into about 3-4mm but the new one were far deeper then the previous one.  I think it is just a way of balancing the crank by removing a bit of weight rather then adding too much. Although I will try to confirm more on this from RE. Now is there any difference I observed with the new heavier or well balanced crank? Hell yes! there is something about it which I instantly noticed. Previously I observed the vibrations used to start to creep up on handle bar above 100 and quite bad at 125 plus. Now I have more vibration at 60 or should I say I can feel the thump till 60 and as soon as I accelerate, it vanishes. I really mean there is nothing I feel in the handle bar and it does not stop there. To give you an idea how smooth it is, its like when you are doing 80. If I close my eyes and plug my ears, I won't be able to tell if I was doing 80 or 115km/h. So in short, 60 to 115 is way too smooth. Only around 115 the vibrations start to creep up but nothing like I used to experience before. I feel the top end will be far more comfortable then I had experienced at 140. My bebe is way too smooth now. Kind of loving it and hating it at the same time. Come on RE, thumpers are all about vibrations and you have taken away the love out of it. @Nasir- can you feel any grooves formed on the disc rotor? Can you post a picture of the rotor please. Last edited by Randhawa : 2nd December 2010 at 21:21. |

| |  ()

Thanks ()

Thanks

|

| | #928 | |

| BHPian Join Date: Mar 2010 Location: BLR/MAA

Posts: 55

Thanked: 4 Times

| Quote:

please tell us no..? please tell us no..? | |

| |  ()

Thanks ()

Thanks

|

| | #930 |

| BHPian Join Date: Oct 2010 Location: Pune

Posts: 52

Thanked: 0 Times

| @Nasir: Well apparently the rear wheel bearings were faulty. Got them replaced and the noise is gone. @Randhawa. Now heres where i made a terrible mistake. In my quest to make my bike problem free i ended up showing atleast 3 mechanics in my city. 2 were authorized and the third one has an extensive experience in the older REs. Now i got the 1st servicing done at one of the authorized service center. And then someone suggested me the other authorized service center. The guy there convinced me that i had minor tune up problems in my bike and he got the chain cover opened and the chrome part of the engine just under the petrol tank. I think he tightened the autodecomp on the timing gears and he put back the covers again. Nothing has changed in my bike except for the addition of one more noise from the engine. I should have stuck to only one mechanic for atleast the 1st 4 servicings. Ok...here is a general thought. this is my first Enfield and the reason why i bought one was because i wanted to experience good amount of thrust pushing me and high speeds that i can only dream of on any of the other bikes in the Indian market. I ended up spending 1.5l for the same and here are my thoughts: 1. No peace of mind since the day i bought her.Primarily because i invested such a heavy amount from my 1st job and here i am investing more money and time to get my "BRAND NEW BIKE" trouble free. 2. Terrible terrrible machining. Build quality is very poor.Feels like RE is still using machines which they found in the ruins of Harappa and Mohenjodaro. 3.I get a feeling that RE thinks that they are doing a favour by producing a bike in 1,5l and that the customer should be paying them much more. 4. RE has no bench mark that i can compare my bike to and be satisfied and have a peaceful sleep. 5. With such never ending problems i am going to be of the opinion soon enough that RE looks good parked in other people's garage and not yours. 6. Yes i am very frustrated, irritated..etc. It hurts so bad to know that my bike has problems and that i am unable to solve them and to top all that the mechanics, the dealers, throw bull**** at you day in and day out when those are the only people u can trust.It hurts to hear noises coming out of my bikes engine with every beat and i know that they are killing her slowly.I only wish for a trouble free bike for atleast the 1st six months.How difficult is that for RE to deliver? 7.To sum it up i am having a very painful experience with RE right now.I have a feeling that this will be my last RE unless some angel comes along and changes everything. I just cant see my bike suffer and with RE that is going to be difficult. 8. In any case i just cant give up on my bike, i am going to do whatever it takes to fix her right. Please  do help me out. do help me out.Last edited by cooded : 2nd December 2010 at 23:43. Reason: wrong grammar |

| |  ()

Thanks ()

Thanks

|

|