News

Did a Bhilai-Pune road trip in my XUV700 for a Mahindra plant visit

At the entrance of the Samruddhi expressway there is a huge round-about and the road is illuminated for quite a distance, which makes it prominent in the dark night.

BHPian Sommos recently shared this with other enthusiasts.

Drive to Pune - M&M plant visit:

One fine afternoon (28th April) received the above invitation from M&M. Dialed the toll free number, as soon as I could, and booked a slot. In the evening narrated the whole thing to my spouse; I knew that she would be very excited, as visiting Pune means a chance to meet and stay with our son.

During May I was busy with Annual Accounts Closing and statutory audit and there was no further communication from M&M. Sometime in the third week of May rang up the toll free number again and asked for confirmation. They verbally confirmed our booking on 27th May (fourth Saturday) and informed us to proceed with hotel booking and other planning for the journey. Our stay was booked at Courtyard Marriot, Chakan, which was very near to the M&M factory. The route would be Bhilai-Nagpur ORR-Samruddhi Mahamarg up to Shirdi-Pune (Chakan). Had read many stuff about accidents and lack of facilities on the Samruddhi Mahamarg – so was in a bit of dilemma. Sufficient dry fruits, sweets and other snacks were carried in anticipation.

The Journey:

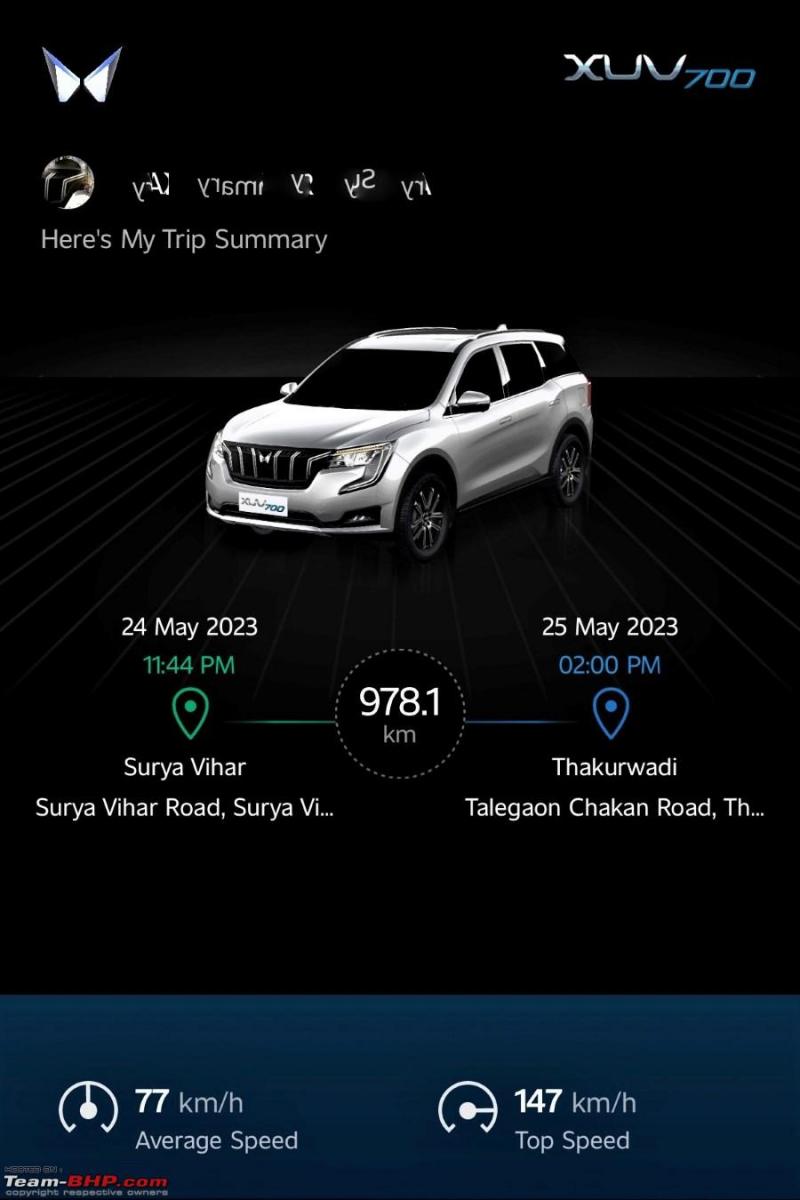

Started just before midnight of 24th May from our home and Bhilai to Nagpur drive was smooth. However, I had to search quite-a-bit to feel up the tank before entering the express way. Finally found a BPCL pump that was open just before entering the Hyderabad by-pass and filled up the tank. Crossed the toll both on Nagpur ORR at 03:56 AM and may have entered the Samruddhi Mahamarg 15/ 20 minutes after that.

At the entrance of the expressway there is a huge round-about (I noticed this only while returning back) and the road is illuminated for quite a distance, which makes it prominent in the dark night. Had heard many stories of police checking the vehicles, specially the tyre conditions at the entry to the E-way. Frankly I did not witness any such checking either at Nagpur or at Shirdi entrance during the return journey. There was very scarce traffic from Nagpur side and the triple lane E-way was empty. The lanes are very clearly marked and the left lane is for HV, the middle for LMV and the right lane is overtaking lane. There is several signboards with the above instruction as well as showing the max speed limit for each class of vehicles. Set the ACC at 105 KMPH and had a cool journey for about six hours on the Sanruddhi Expressway. Though this is an access controlled E-way, but I did notice a couple of bikes – don’t know how they managed to enter. The e-way was blocked with barricades at Shirdi indicating the end of the road – which was opened up on the very next day till Mumbai. Overall it was an extremely soothing experience. The toll from Nagpur to Shirdi was Rs. 900.00 and the exit time at Shirdi toll gate was 09:55 AM.

We realized that we should have carried tea/ coffee in a flask as you would not get any decent tea / coffee on the route. We decided to have our breakfast at the Marigold Regency, where we had stayed earlier. After a refreshing breakfast with a cup of tea & coffee and an hours break, we started for Pune. There were several crossroads in this part and I had trouble staying on route as the Vi sim of the XUV700 lost connection and the maps started behaving erratically. Finally, wife’s Android mobile came to the rescue and we reached Courtyard Marriott, Chakan, Pune at around 02:00 PM. The check-in at the hotel happens at 03:00 PM and we had to wait one long hour at the lounge, however, as a compliment they up-graded our booking to a suite.

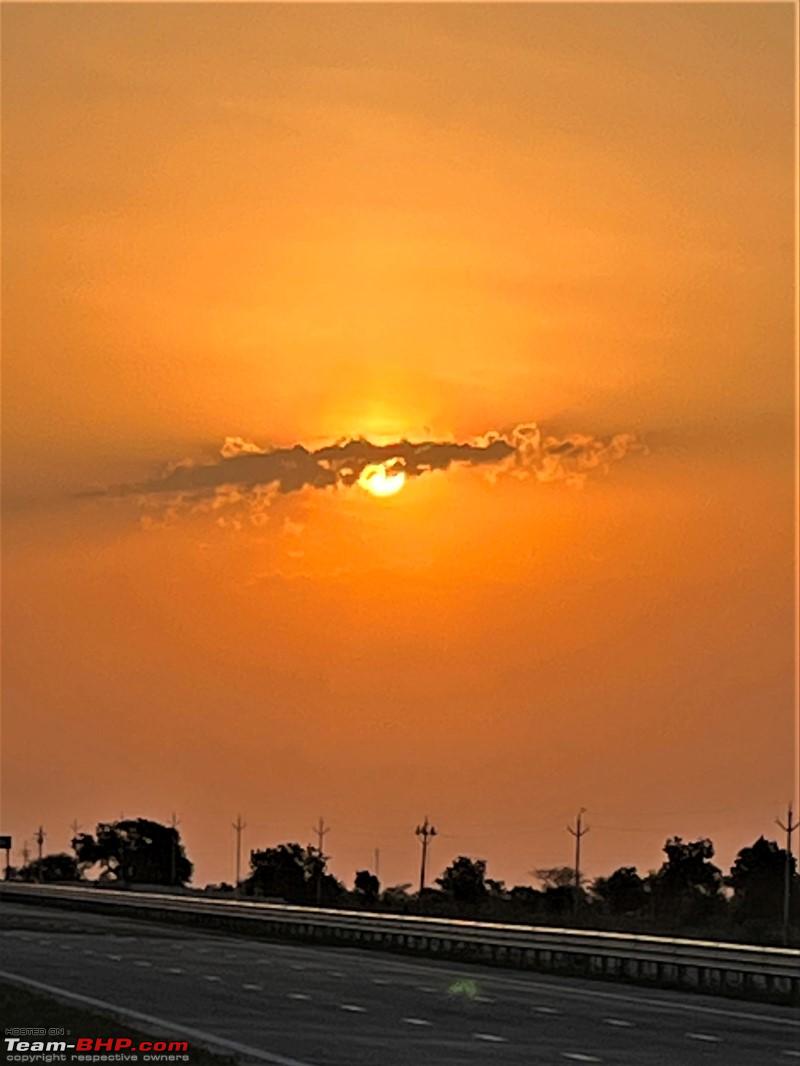

Some pictures of the morning sun on route:

26-06-2023: For the next two days I did not get to drive the car as the keys had been taken over by my son. At the end he was thrilled to have driven such a big car in the busy roads of Pune without any words of caution from me. We spent our time in the Pheonix Mall and also went to Tiger Point, Lonavala to enjoy the sunset. On our return from Lonavala, in the evening we also had an experience of the horrific traffic on the Mumbai-Pune H-way.

Mahindra plant visit (27-06-2023):

Just after entering the gates of the plant, we were instructed to park our car in an area, which was earmarked for visitors. Just opposite to the parking area was the reception where we had to enter our details (KYC documents were already submitted to M&M earlier). They had arranged a bus to carry the visitors, but since we were early, we were taken in a XUV500 to the Body Parts Shop, where they had arranged for breakfast. There were total 42 confirmed bookings out of which 36/37 turned up. Slowly everyone arrived by 09:30 AM and there was a brief introduction with presentation and instructions. Some guest was provided with safety shoes and aprons by the team and we finally started the visit at 10:15 AM.

The following shops were offered by the team, and the group can choose any three

- Press Shop

- Body Shop.

- Paint Shop and

- Assembly Bay.

Test drive on their internal test tract with demonstration of all the ADAS feature (mainly for those who have not received their car yet) was also part of the programme. The group decided to skip the Press Shop and visit the rest.

The Body Shop: The monocoque structure consists of three parts – the rear (from second row seat to the boot), the mid (front of the second row to the dash) and the front (i.e. the engine bay). All the three parts are fed to the production line from three different conveyors from the sides and welded together by robotic arms to form one single piece.

In the second part the sides are fitted in place and welded and in the third part the roof is fitted in place. Each and every body is machine checked after this stage.

The paint shop : The Electro coating area was not shown to us. The group was taken straight to the area where the sealants were being applied to the cars. At an intermediatary stage the sealant application was being manually inspected and corrected by manual intervention. One floor above this is the ultimate production line where the base coat and the clear coat is applied and the whole line is vacuum sealed. The final product is manually checked by a group of technicians for certification/ rejection.

The certified painted bodies are stored in a huge multilayered frame sort-of structure within the same building.

The Assembly Shop/ XUV 700 Shop: This area was huge in size and spread and the group was allowed to walk in only one straight path where we could observe men working on both sides. Here the production line keeps on moving at a set speed and each group moves with the vehicle (up a small distance) and perform their job at the same time. Each group/ work station consists of four to eight technicians and each team is entrusted with performing one particular job like one team fits the engine & front suspension, the next fits the dashboard etc. Each work station is fed with the required/ designated assembly from the side. Each and every team works in such unison and cohesion and also completes the job within the schedule time – it was really beautiful to watch the groups perform.

At the end of this production line we saw how a naked automobile body transforms into a beautiful piece of engineering marvel. One batch of KUV100 cars were also being assembled in the assembly shop. They were LHD and for export purpose. This is one shop where the group photo was taken and we also took liberty to snap a couple of shots.

The Test Track: After coming out of the assembly shop, each-and-every vehicle is tested in the test track to check the suspension set-up, the alignment and the ADAS features and finally certified as “ready for dispatch”. M&M has a small 2.5 KM test track within the plant for this purpose. Our group was taken to the test track prior to the Assembly shop visit and the purpose was to explain and demonstrate the ADAS features in real driving conditions. The prospective buyers were very excited to experience live demonstration of these advance safety features – mainly the Lane keep assist, AEBS and the ACC.

The plant visit was followed by lunch at the Courtyard Mariott, Chakan and each were gifted with a M&M coffee mug and leather key chain before they parted.

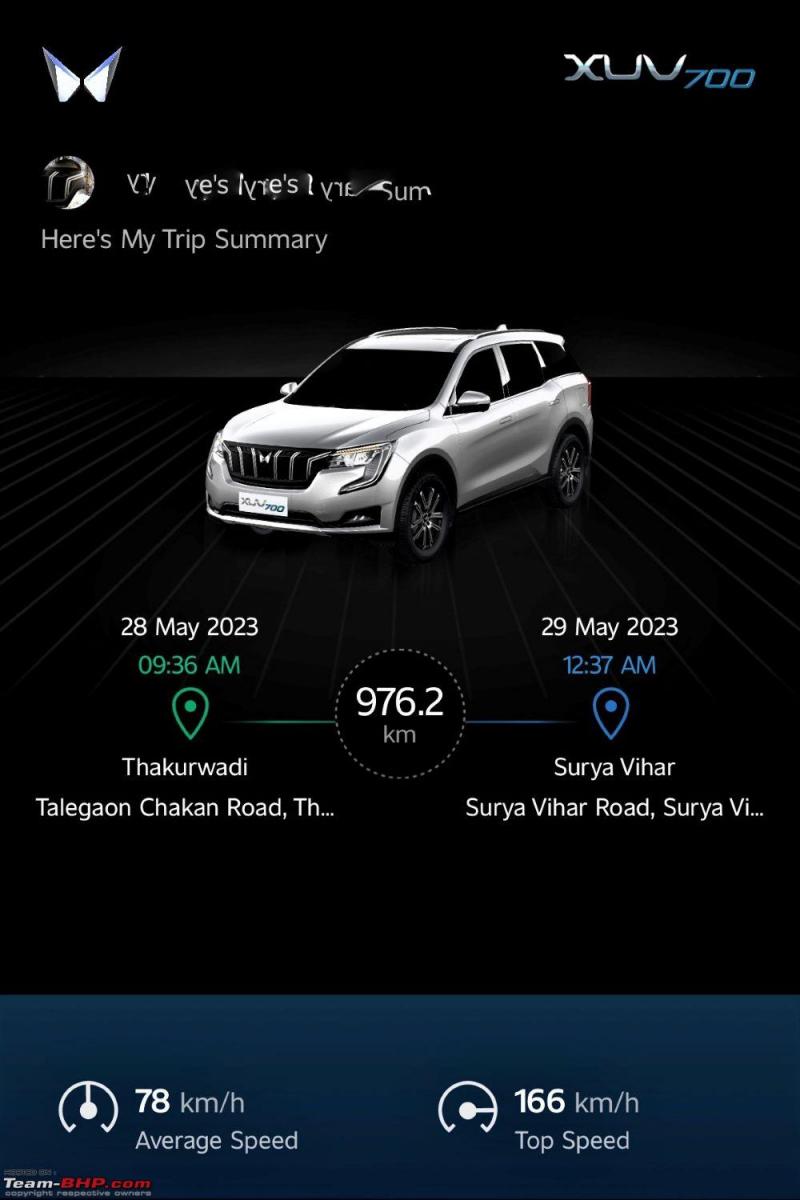

Return on 28-06-2023: We returned to Bhilai the next day via the same route. In spite of all our efforts we could start only at 10:00 AM and reached home half hour past midnight. Our return journey till Nagpur was uneventful but after that we lost two hours due to road blockage at three different spots by the local admistration (for reasons unknown to me) plus we had to stop for dinner on the way.

During our return we saw an accident (may have occurred some 10/15 minutes before our arrival). The car was a grey coloured hatchback, which had turned 180 degrees and the front left hub seemed broken. Six / seven cars were already there and people were helping the victims out of the car. One aged lady, with multiple cuts & bruises on her body, had just been taken out of the back seat and she was seating on the road. Another lady was still there on the rear seat.

At the end of the day, Orion brought us safely home after a memorable driving experience.

The Shirdi and Nagpur toll:

Road ahead:

Onward & return journey stats:

Lonavala:

Check out BHPian comments for more insights and information.