News

Imperfect engine displacement & power figures in vehicles

I have googled a few times and have not found a convincing explanation yet for the "imperfect" engine displacements. I found one of the explanations interesting though.

Emvi recently shared this with other BHPians.

I have always been curious to know why are engine displacement and power output figures not a "perfect" number in automobiles!? Elaborating a bit further, when I say "perfect" I mean, from a 100cc bike to a 7.0L engined truck, neither the bike's engine is perfectly 100cc nor the truck's engine displacement is exactly 7.0L and so is the case for all the vehicles with various engine capacities. In addition to this, the power output figures throw quite interesting numbers too.

It is understandable that on occasions, manufacturers deliberately design and manufacture engines with "imperfect" displacement figures in order to comply with regulations that are in place in some countries/regions. For example, in India, the engine displacement for a "small" car shouldn't exceed 1.5L for a diesel and 1.2L for a petrol to comply with the "small" car tax regulations. So, invariably the engine displacement is kept below the limit at least by a cubic centimetre (cc)! A similar exercise was followed by Mahindra to comply with government regulations when they downsized the XUV500 engine to accommodate it under the sub 2L engine classification.

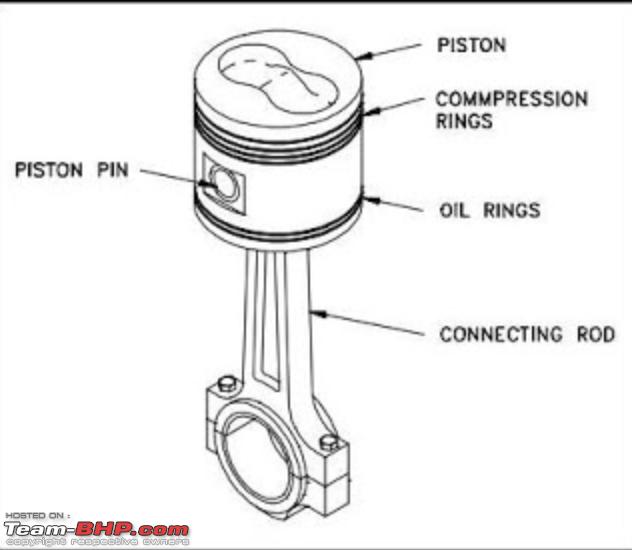

I have googled a few times and have not found a convincing explanation yet for the "imperfect" engine displacements. I found one of the explanations interesting though. πr²h is the mathematical formula to calculate the volume of a cylinder, where r=radius, h=height of the cylinder and the value of π=3.1428. Since π is not a whole number, the volume of a cylinder or in this case, the volume/displacement of an automobile engine is never a perfect number! Interesting, logical! So each and every cylindrical component in this world is imperfect dimensionally or in other words, the volume of a cylindrical component is never a perfect/whole number? I honestly don't know.

The way certain engines are classified by the manufacturers is quite bizarre as well. Curiously enough, the legendary 1.3L multijet Fiat engine is actually 1248cc! So it is essentially 1.25L and for the purpose of classification, logically it should be 1.2L, no? Another such example is Kia/Hyundai 1.4L GDI engines, which are actually 1353cc! There are plenty of such examples in our country and around the world.

Now coming to the power output figures in terms of BHP/PS and torque in terms of Nm, more times than not, these figures are not "perfect" numbers, are they? So, while designing and developing an engine, what is the thing that the engineers focus on? Do they develop an engine with displacement as the constraint and see how much power an engine can develop or do they decide on the power output requirement and then arrive at the displacement? Either way, it requires engineering and mathematics and I repeat why are these figures not perfect!? Consider Hero Splendor- 97.2cc engine capacity, 5.9kw or 7.912 BHP of power and 8.05 Nm of torque! Wow!

It is important to note that the dimensional deviations within prescribed limits are always allowed in the manufacturing industries owing to the practical issues in the machining processes, which are generally called machining tolerances. This may also add up to the imperfections in the dimensions and power output figures, of course not significantly. This further pops up a question in my mind. Now again taking Hero Splendor for the purpose of discussion, if each and every Splendor manufactured is identical in terms of engine capacity and power output figures, 97.2cc and 7.912 Bhp!? If they are not, by how much?

Precision engineering is one of the key elements in the automotive industry. Ironically though, certain noteworthy aspects in an automobile are far from being precise/perfect, like the one in the discussion, at least numerically.

Here's what BHPian Jeroen had to say on the matter:

Certainly, when it comes to engine displacement, it is completely useless to aim for a round number. The required displacement and power output are associated / depending on a whole lot of other factors.

If anything, from a production point of view, something like a bore is nice to have as a whole number, which will always lead to a not rounded number of displacement obviously.

It is not a result of tolerances in the machining process. Dialing in 20mm in the milling machine is less prone to mistakes, than say 19,87625568 mm.

Production tolerances are so small they don’t even show up in these sort of calculations. Bore and stroke are machined within less than thousands of a mm.

In essence they are just rounded numbers, because anything else doesn’t matter.

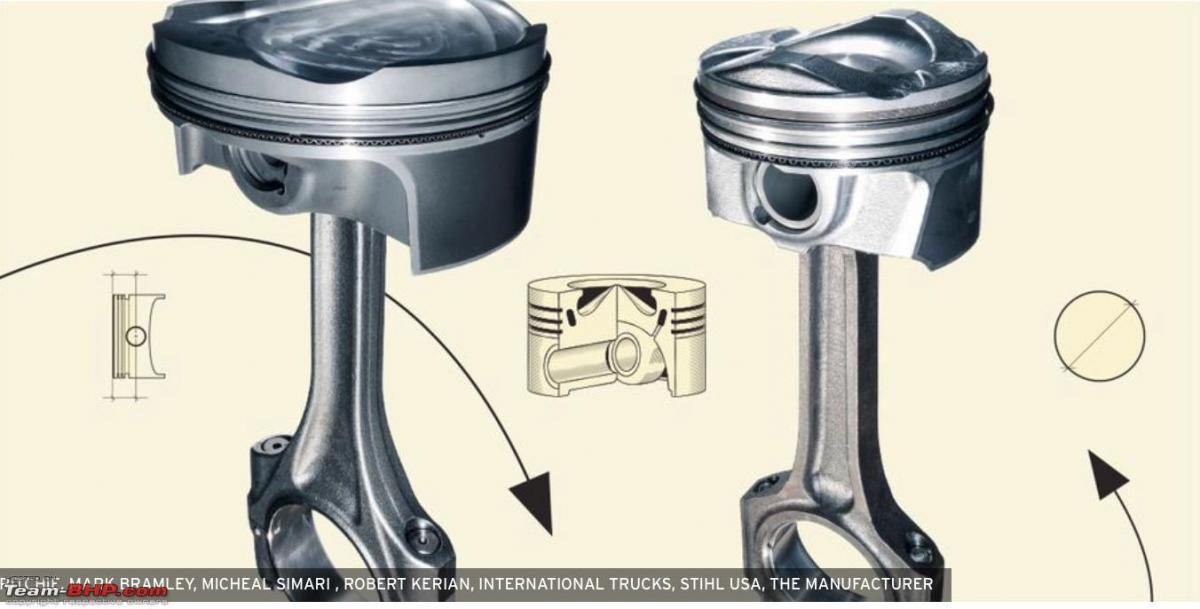

The discplacement/volume is not calculated using the height of the cylinder, but primarily the stroke of the piston, which is always less. And even that is not entirely true. The displaced volume is also depending on the volume trapped between the cylinder / piston and top piston ring (assuming no leakage). Also, your piston might not be flat on the top. It can be rounded, or have indents. So you need to add for that as well. So you have to add or subtract a bit.

Here are a few examples:

You can calculate it if you have all the dimension. Or you can measure it. Put the piston in the bottom end position. Take the spark or injector out, fill with oil to the brim, now carefully rotate the crank through 180 degrees to get the piston to top bottom position. You need to carefully measure the oil that spills out; the volume of oil displaced is the exact volume/displacement of that particular piston/cylinder.

I have done it a few times at Naval Engineering school on some marine diesels. It was interesting to measure the differences between cylinder, as an indication of potential wear without having to take the cylinder heads off.

Check out BHPian comments for more information and insights.

- Tags:

- Indian

- Other

- Engine

- Displacement

- Power

.jpg)