Team-BHP

(

https://www.team-bhp.com/forum/)

This time LT broke and then right cracked. Khan has the broken leafs with him now, so he should be able to post better pictures.

@ Spike - Why am I getting the feeling that MM is experimenting with CFLS. Right or wrong?

Regards

Sutripta

I wanted to see if there is a similarity in failure pattern, how did it shear off etc. Why do you have this ^^ feeling?

Spike:D

spoke with Dr Pawar.

I didnt know that there were 2 types of CFLs available, one for hardtop and one for soft top.

Quote:

Originally Posted by Desmosedici

(Post 2049791)

spoke with Dr Pawar.

I didnt know that there were 2 types of CFLs available, one for hardtop and one for soft top.

|

Really? The difference in the weight between hard and soft top variants is just 35 Kgs!

Is there any other factor which might force them to make a different CFL for hard-top variant?

thats the only difference Dr Pawar mentioned, to take care of the additional 50 odd kgs. Sounded a bit strange to me that for a 50 kg payload we would have 2 sets of CFLs. Anyways i am going to go for the hardtop CFL, as i plan to fabricate a partial hardtop made of metal.

Cost is 10K

Quote:

Originally Posted by SPIKE ARRESTOR

(Post 2049090)

I wanted to see if there is a similarity in failure pattern, how did it shear off etc. Why do you have this ^^ feeling?

Spike:D

|

To Diplomat/ Lawyer/ Politician Prateesh,

So in absence of a definite answer, I take it as a yes. :)

Regards

Sutripta

Quote:

Originally Posted by Desmosedici

(Post 2049892)

thats the only difference Dr Pawar mentioned, to take care of the additional 50 odd kgs. Sounded a bit strange to me that for a 50 kg payload we would have 2 sets of CFLs.

Cost is 10K

|

Strange is not the word, it sounds like a very silly statement to make, which leads one to casts doubts about whether the man knows what he is doing.

I would make the call on the basis of the load you will run the car with. 4 passengers plus luggage in addition to 2 in front would mean 300 kilos more load than just one/two up. I would think that the harder version would be better for loaded car use, while the softer version would work better if you used the car without load much of the time.

Basically though it is the garage/jugaad nature of this solution that has kept me away from it so far.

Quote:

Originally Posted by khan_sultan

(Post 2039930)

I guess I spoke tooo soon :Frustrati. I broke the 3rd set this weekend in the Sowmerpet trail.

The front left leaf broke/snapped at the point where the rear joint is. I was reversing the tyre over a 2ft boulder and it could not take the compression (-ve compression force) applied. I don't know if the -ve camber ability of these is adequate. Also, once the front left broke, the front right also could not take load and started splintering.

|

Sir is it possible that the leaf broke because of axle wrap? As you were reversing the front axle was experiencing the same stress which the rear one does in forward motion.

Do you have a traction bar for the front axle also?

This is my first post, but been lurking here for a few months. Just shifted to bangalore from california and looking to start a restoration project of some kind.

Khan_Sultan - In one of the events, I have seen a leaf set up for a samurai with a CFL over the axle AND a single leaf under the axle as well on extended shackles. The shackle was modified to accomodate both the leafs, with the leaf under the axle playing a secondary role after the cfl leaf absorbs the initial impact.

I have seen this set up in tractors and heavy trucks, where there are leafs under and over the axles on two sets of shackles to acoomodate the load. The samurai version was done with a analogous but different objective - to support the cfl beyond a certain point.

Could this be an implementable idea in a DIY effort? This could be a potential model for the front axle cfls so that the extra torsions are absorbed and gives insurance/peace of mind as well.

PP

Quote:

Originally Posted by gadgetman

(Post 2112850)

....

Khan_Sultan - In one of the events, I have seen a leaf set up for a samurai with a CFL over the axle AND a single leaf under the axle as well on extended shackles. ....

Could this be an implementable idea in a DIY effort? ...

|

Interesting. Well, do you have any pictures of sketches of this setup? I would be willing to try this out and ready to experiment if we have the sketches. In absence of the pictures it becomes very difficult to explain to the fabricators here :Frustrati.

Am game.. -- especially for the front, as I have the rear sorted out already.

khan_sultan - Unfortunately, I dont have pictures. I will describe as best as I can remember, it seemed simple enough!

1. perches on top and bottom of axle - seating the CFL leaf on top as SPOA and the single steel leaf on bottom as SPUA.

2. A pair of C bolts (rather than U) holding everything together

3. The steel leaf was a high arch version. It wasnt heavy duty as its purpose was as a secondary support. The CFL had a modest postive camber.

4. The distance between the perch surfaces for the leafs was about 3 inches.

5. The shackles bushings on each side of the leaves was on plates about 5-6 mm thick welded to chasiss beam.

6. The plates had multiple holes about 1 inch apart to change bushing placement, suggesting it was a bit of trial and error. I would say the distance between bushings was about 3-4 inches.

7. The steel leaf was on a single shackle on the front

I guess the the high arch of the SPUA steel leaf, its (longer) length and the shackle placement and the hang length of the shackle determines when the secondary leaf starts to take the load after the initial load absortion of the primary leaf. Will see if i can sketch this out but on the road through next week so may be delayed.

I will PM you for your contacts.

PP

In case of the conventional steel multi-leaf springs, one can vary the stiffness by adding or removing a leaf, according to the requirements. But this may be difficult to do with a composite leaf spring.

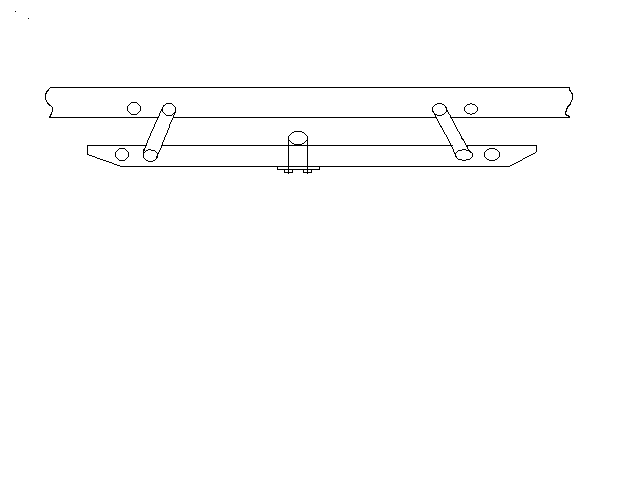

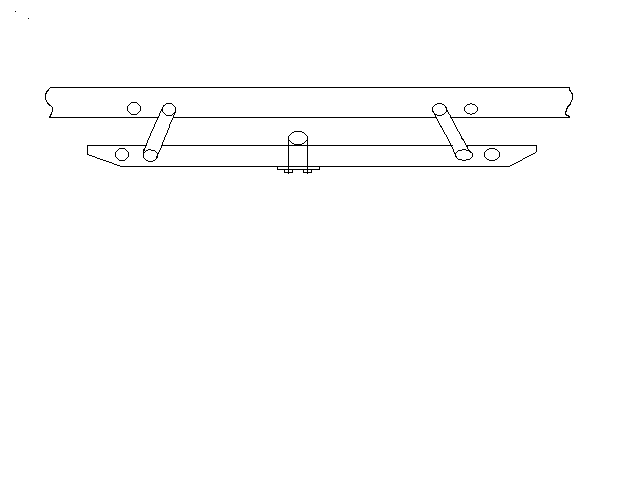

However, I wonder whether it could be possible to have an arrangement which I have thought of (depicted crudely below without the camber angles etc. by using Paintbrush to the best extent!) :

In case a softer ride is required, just move the shackles to the outer holes. Maybe longer shackles will be needed at the outer holes to maintain the ride height / bump stop clearances.

To go a step ahead, instead of the extra holes, one could also have a slot with suitable packing (to fill up the extra slot volume) to have the hinge point at any desired length, to offer a wide variety of spring rates.

Some thoughts on this would be welcome :)

Has someone installed CFLs at the rear-end Ford Endy and has done Leh? How has been the drive. I intend to do the same this year (from Mumbai) with luggage in the rear and 4 healthy people in the car. If it works, i.e., the ride improves and the durability doesn't get impacted negatively, then I would like to look for it. How much would they cost and where could one get it in Mumbai?

I am being quoted 14k for front and rear of Gypsy for a total of 28k by ARC here. That's a 40% increase over the 10k price quoted to Desmo in Aug 2010!!

I don't feel it is justified. What are the other options to improve suspension?

--ragul

Edit: just spoke to Dr. Pawar. The width of the leaf has increased to 5" from 2.5. And there is now a supporting plate for the CFLs and also a buffer/bush provided. This is for the rear.

The front is now 3", the max width possible. This change was made in the last 4 months. Another improvement he mentioned in an earlier call is that the leaves now handle stress in upwards and downward directions better (did he mean negative compression stress?). I am no mechanical engineer and a complete dud at all these things. So your elaborations or corrections on the above are welcome.

| All times are GMT +5.5. The time now is 14:26. | |