The head gasket installed back in December proved to be leaking just slightly after the return to Manali. No coolant in the oil or vice-versa, and no real symptoms at idle speed, BUT under load (like every time we have to drive uphill), combustion leakage into the water jacket is evident. First effect was that pressurized air leaking into the block side of the cooling system was:

1) holding the thermostat shut; and 2) displacing coolant, causing overheating and also forcing that displaced coolant out into the overflow tank, filling it to overflowing.

Before I understood what was happening and why, I'd replaced the thermostat, thinking it faulty - which of course didn't help. Ran fine without the thermostat, since air escaping into the head area was free to flow up to the top of the radiator and out into the overflow tank. Lot better to let air out than water!!! But without the thermostat, the engine never really gets up to temperature, thus impurities / deposits in the oil and on the valves, etc, probably never get evaporated / burned off, and of course clearances between hot pistons and relatively cooler cylinders are going to be too tight, and etc, etc... so not good for long-term health.

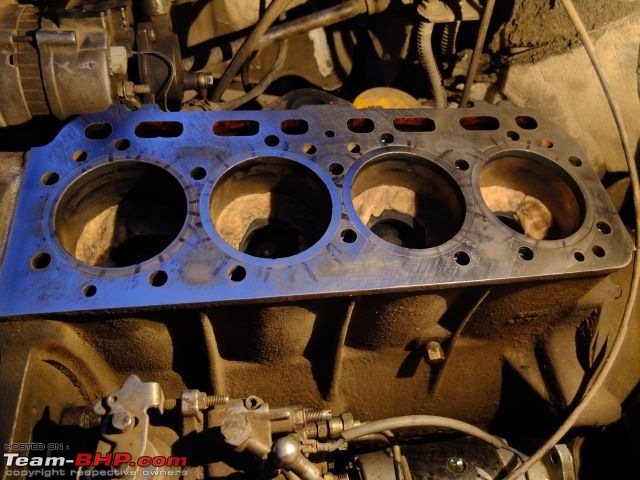

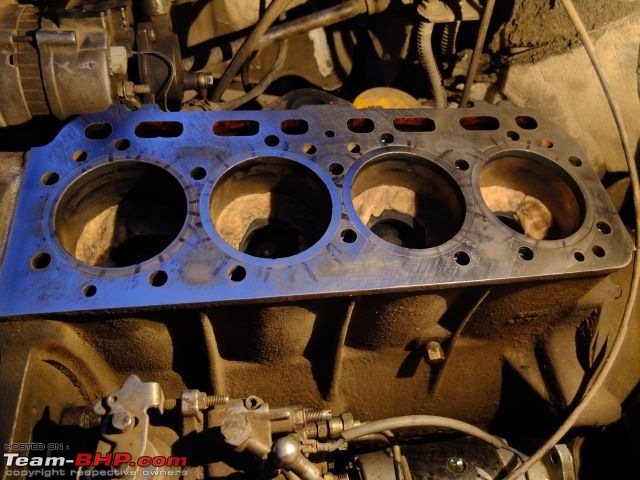

So I changed the head gasket myself, getting the head re-faced this time (it was suprisingly out for a cast-iron piece). Unfortunately, leakage situation didn't improve. Ran it a month or two, researched some, and figured I'd try again. This time did some hand-facing of the block deck with plate glass and emery cloth, as liner stand-out (protrusion of the cylinder sleeves above the block deck) was not consistent between cylinders and I figured I could even them up this way. Seems to be within a thousandth flatness overall now, though the liners are hardly above deck. Used a little aluminum paint on the steel rings of the head gasket, with some .010" copper wire attached under the rings, and some special sealer elsewhere.

Frustratingly, STILL DIDN'T WORK.

Thinking I'd overdone the j

uggad a little, tried again a few days later, this time with an original, untreated genuine Mahindra gasket.

DIDN'T WORK.

In fact exhibits much more leakage than earlier. Starting to wonder if it's something other than the head gasket (imperceptible crack in cylinder liner? Wish I'd bought that spray-can of Magnaflux I saw last time I was at Ajmeri gate, Delhi).

So here I am, few days of labor, two trips to Mandi, and some paise later: Almost complete, well-running vehicle that unfortunately has this internal leakage issue and thus is not suitable for anything but limited local use. Doesn't overheat anyway, nor push water out so long as the thermostat's out. I can still drive through our overflowed river and still pull tourists out of the local drains regularly...But not going to attempt crossing over Rohtang if it's like this.

So gotta either:

1) Figure this out, or

2) Risk a few hours' drive to Mandi and let them dismantle / examine / machine / replace / reassemble everything (but not sure whether even the best guys there have the facilities to check for micro-cracks or to re-machine things like sleeve shelves (counterbores), or if they have things like sleeve shims, so no real guarantees there as to whether I might get the same "chalega" approach and have the problem reappear again in a few months, as has happened with the "specialist" in Chandigarh....); or

3) Buy a second-hand replacement engine, whether another 15-year-old DI unit (being quoted Rs25,0000 complete, which seems high in light of the presently quite high supply / low-demand situation here), or a 2011-model MDI3200TC turbocharged unit at 45,000, including the larger radiator and silencer/pipe etc (currently mounted in a Mahindra Maxx people-carrier, which is pretty similar to the Marshal except for the body width).

Can hear both these engines run before purchase, and both come with a guarantee. And incidentally, as per a personal conversation with the RTO earlier, there doesn't seem to be any issues obtaining permission for the turbo upgrade - important as the car will have to go for passing next year (15 years).

Really wish this could've been resolved with a Rs450 head gasket and a few hours' labor, but we're way beyond that.

ANY IDEAS?

I'm basically satisfied with the standard DI's performance, and if it's built right, it is supposed to be one of the most robust / reliable / simple engines out there. If I'd be able to get my issue resolved with my original block, I'd be happy and would spend a lot less money than going for a replacement.

On the other hand, no denying that the turbo really has what feels like the "right" amount of power for this weight of car, and I'd be able to run it as-is, an un-opened, original, four-year-old engine, vs. having to deal with the unknown levels of

juggad that have been applied to any non-turbo DI, which will be a minimum of ten or eleven years old by now and most heavily used. And what I'm finding so far with most things on this car is that when I get a couple things resolved, at least one new issue shows up to deal with.

What I'd REALLY like to have is the M&M company service manual, which would tell me the specs for things such as cylinder liner protrusion, etc. Found them for what I guess is its predecessor, the old International Harvester D-414 series engines (same displacement and presumably basic block) - but not sure those would be the same on all points.

Thanks in advance,

Eric

(3)

Thanks

(3)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(3)

Thanks

(3)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(1)

Thanks

(4)

Thanks

(4)

Thanks