Team-BHP

(

https://www.team-bhp.com/forum/)

Quote:

Originally Posted by pixantz

(Post 3795108)

That also may be very much possible. Or mayhap there is no databases anywhere at all. The elm or cables just do the transfer part and the softwares whether on PC or mobile decode/decipher the can info and communication offered by the ECM in the required protocols. Rest is the price of the software which determines which algorithms of how many manufacturers or how detailed a reading it can cough up.

|

I have several OBD analysers. The most versatile is this one:

https://www.autoenginuity.com

Standard it will allow you to scan all standard codes. Per manufacturer you buy for an additional fee all of the manufacturers specific codes. It also provides a host of static and dynamic measurements. With it you have more or less the same analytic capabilities as any modern main stream dealer. But it comes at a price, obviously.

Jeroen

I ordered SuperMini ELM 327 v2.1 and got it from amazon. I have got the Torque Pro installed in my Samsung Note 2. It paired and detected the ECU and connected fine and was very easy :thumbs up. The vehicle is Vento TDI Highline (2011).

Just to try out, I have selected few PIDs for logging and started the engine to see if it actually logs the data. The engine was idle for about 15 mins. It did capture the log and I was able to get the .csv file.

I have few questions / clarifications for the experts (trying to learn :D):

- Engine load (%) started at 51% and gradually reduced and settled around 30% at the end of about 15 mins. There is no load applied (No AC, It was in neutral). Is this normal?

- Volumetric Efficiency (Calculated) started at 55% and settled at 70% after 3 mins. Is this normal? Would the Volumetric efficiency increase when engine is loaded? What is the normal range for Volumentric efficiency?

- Find below the EGR Commanded and EGR Error values. How do I interpret these values? Are the normal or I need to be worried? I have given only few sample rows from the log and for the entire duration the values are in the same range.

Quote:

Originally Posted by AutoInt

(Post 3804087)

I have few questions / clarifications for the experts (trying to learn :D): - Engine load (%) started at 51% and gradually reduced and settled around 30% at the end of about 15 mins. There is no load applied (No AC, It was in neutral). Is this normal?

- Volumetric Efficiency (Calculated) started at 55% and settled at 70% after 3 mins. Is this normal? Would the Volumetric efficiency increase when engine is loaded? What is the normal range for Volumentric efficiency?

- Find below the EGR Commanded and EGR Error values. How do I interpret these values? Are the normal or I need to be worried? I have given only few sample rows from the log and for the entire duration the values are in the same range.

|

the engine load shows the how much percentage of the peak torque ( available at that RPM) is being used.

I think the volumetric efficiency you have to feed in at settings of the Torque pro app. As per Torque pro, the usual volumetric efficiency is 85%.

The EGR commanded is from the EGR valve position. What you are reading may not mean that EGR is flowing, since Usually EGR valves need more than 30-40% to get some flow that will reduce emissions. The EGR error is the difference between the EGR that the ECU is asking for VS the actual EGR flowing into the engine

Quote:

Originally Posted by AutoInt

(Post 3804087)

- Engine load (%) started at 51% and gradually reduced and settled around 30% at the end of about 15 mins. There is no load applied (No AC, It was in neutral). Is this normal?

|

Is the rpm also coming down and settling during this time ? With Petrol engines, the rpm can be at a higher value at cold start, and when the engine gets warm it comes down gradually.

Quote:

Originally Posted by nijelj

(Post 3805163)

the engine load shows the how much percentage of the peak torque ( available at that RPM) is being used.

I think the volumetric efficiency you have to feed in at settings of the Torque pro app. As per Torque pro, the usual volumetric efficiency is 85%.

The EGR commanded is from the EGR valve position. What you are reading may not mean that EGR is flowing, since Usually EGR valves need more than 30-40% to get some flow that will reduce emissions. The EGR error is the difference between the EGR that the ECU is asking for VS the actual EGR flowing into the engine

|

Thank you nijelj for the clarification.

I was worried about 30% load during the idle while RPM hovered around 800. If this is 30% of available torque at the at this RPM then it sounds fine. I also noticed later switching on AC increases the engine load by about 10%

I have fed the value of 85% volumetric efficiency in Torque Pro application. The range I quoted is during the idle from the start and how it settled down while the RPM remained the same.

Thank you for the EGR commanded clarification. Good know that EGR flow would actually happen only when ECU commands about 30 to 40%.

Quote:

Originally Posted by amalji

(Post 3805209)

Is the rpm also coming down and settling during this time ? With Petrol engines, the rpm can be at a higher value at cold start, and when the engine gets warm it comes down gradually.

|

RPM was between 780 to 800 and this is a diesel engine.

Quote:

Originally Posted by AutoInt

(Post 3805232)

Thank you nijelj for the clarification.

I was worried about 30% load during the idle while RPM hovered around 800. If this is 30% of available torque at the at this RPM then it sounds fine. I also noticed later switching on AC increases the engine load by about 10%

|

30-50% load still looks high for me on a Diesel engine when idling. It could be even due to wrong values given by Torque pro. I'll check this on my Etios, and will let you know.

AC increasing the load by around 10% is ok though.

Quote:

Originally Posted by amalji

(Post 3805250)

30-50% load still looks high for me on a Diesel engine when idling. It could be even due to wrong values given by Torque pro. I'll check this on my Etios, and will let you know.

AC increasing the load by around 10% is ok though.

|

In my case, engine load @ idle ( around 770 rpms ) - 15%

When AC is switched on, increases to 30%

Quote:

Originally Posted by AutoInt

(Post 3804087)

pp[*]Engine load (%) started at 51% and gradually reduced and settled around 30% at the end of about 15 mins.

|

Quote:

Originally Posted by amalji

(Post 3805250)

30-50% load still looks high for me on a Diesel engine when idling.

|

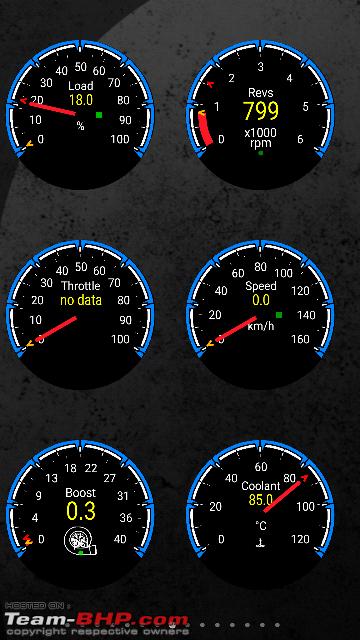

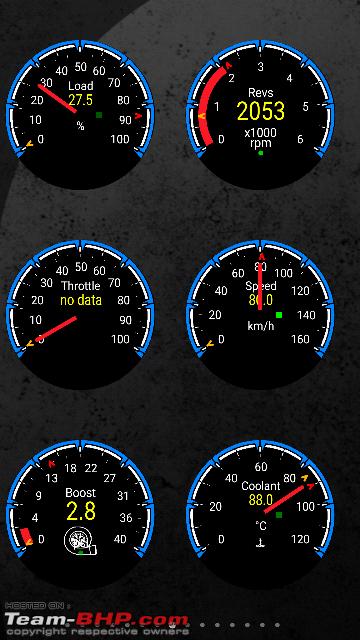

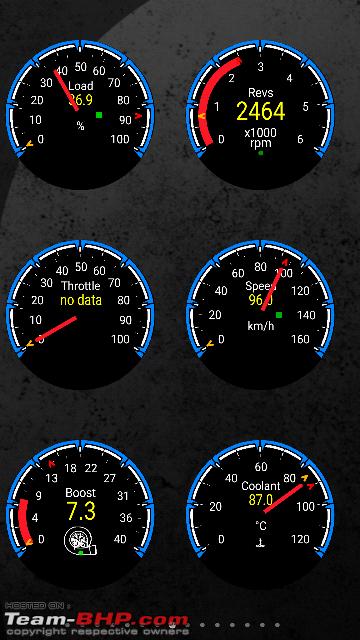

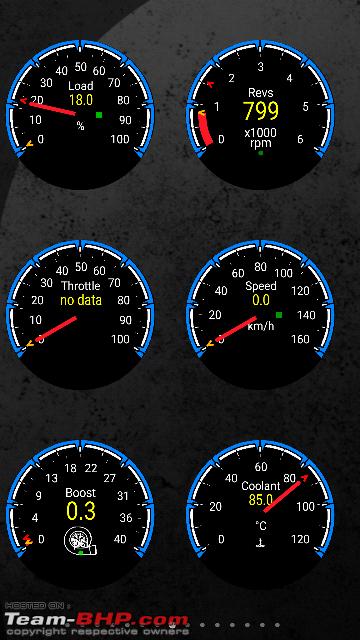

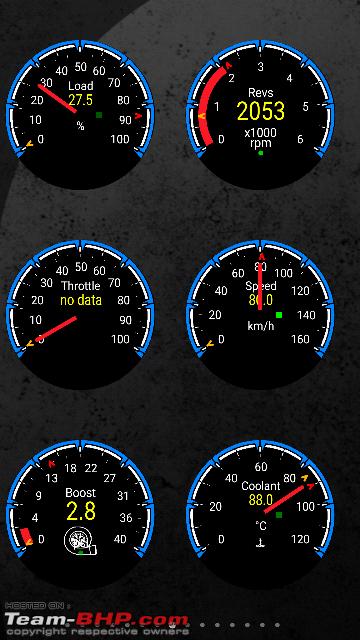

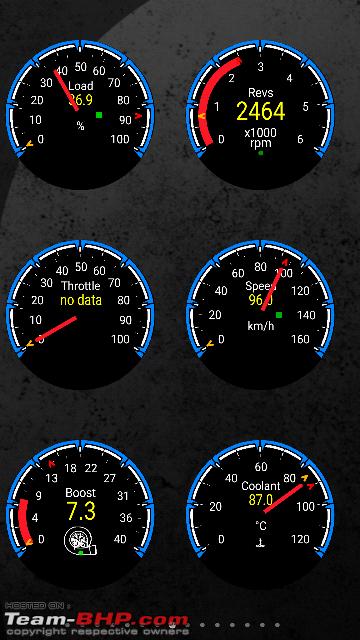

I tried to see what values my Swift ZDi gives for Engine Load parameter.

Here are the screen shots :

At Idle (Without A/C):

At 80 kmph (Without A/C):

At 100 kmph (Without A/C):

At 100 kmph (With A/C):

So what load values your getting isn't right IMO. 30% is high. I am getting 16 to 18% at idle. Hope all electricals are OFF.

Quote:

Originally Posted by a4anurag

(Post 3805287)

I tried to see what values my Swift ZDi gives for Engine Load parameter.

So what load values your getting isn't right IMO. 30% is high. I am getting 16 to 18% at idle. Hope all electricals are OFF.

|

Thank you a4anurag. No electrical were on and no AC either. It was indeed started at 51% and come down to 30% at idle.

I am attaching the logs if you want to have a look at it. One when it is idle and another one while on the move.

All these idle loading numbers are off the wall. When an engine idles there is virtually no load. Idling cold or warm has less then marginal effect on the idle loading which is very low anyway.

Your typical AC would draw 3-5 horsepower max and that includes both the compressor and fan. So 10% is way off as well. Would be interested to understand how this kit calculates loading, because it cant measure it. It can only calculate it based on its input parameters.

Jeroen

I'm finding it hard to understand why are we wondering about parameters and other jargon when a trained technician or mechanical engineer is the apt guy supposed to be worried about this stuff. I mean, it's not like discussing congress bjp politics, no? These are highly technical details/ readings and I don't feel that just about anybody is supposed to understand them clearly. Believe me, those mechanical engineering journals are really thick and heavy. Just saying....

Quote:

Originally Posted by Jeroen

(Post 3805431)

All these idle loading numbers are off the wall. When an engine idles there is virtually no load. Idling cold or warm has less then marginal effect on the idle loading which is very low anyway.

Your typical AC would draw 3-5 horsepower max and that includes both the compressor and fan. So 10% is way off as well. Would be interested to understand how this kit calculates loading, because it cant measure it. It can only calculate it based on its input parameters.

Jeroen

|

Thank you Jeroen for your response. The adapter used is Mini ELM327 Bluetooth EOBD bought from amazon.in and TorquePro application in Android mobile.

Not sure about the calculation this kit uses, I am assuming it is read from the ECU as "Calculated Engine Load Value" is supported by the ECU. The vehicle is VW Vento 1.6 TDI

Quote:

Originally Posted by AutoInt

(Post 3805232)

I was worried about 30% load during the idle while RPM hovered around 800. If this is 30% of available torque at the at this RPM then it sounds fine. I also noticed later switching on AC increases the engine load by about 10%

.

|

Firstly, disregard calculated load value, since the calculations done are very random. So random that this parameter in my WagonR is dependent upon throttle position and commanded idle. So I can switch off the engine, floor the accelerator and yet the calculated load will remain showing some value.

What you can check is the absolute load or actual load PID if that's available. This will be more accurate.

Coming to EGR, the error you see is the behavior of the control system. It is constantly adjusting the position and making small corrections wrt the error in position. You should worry if the error percentage goes to a larger extent than such minute values.

Quote:

Originally Posted by pixantz

(Post 3805455)

I'm finding it hard to understand why are we wondering about parameters and other jargon when a trained technician or mechanical engineer is the apt guy supposed to be worried about this stuff. I mean, it's not like discussing congress bjp politics, no? These are highly technical details/ readings and I don't feel that just about anybody is supposed to understand them clearly. Believe me, those mechanical engineering journals are really thick and heavy. Just saying....

|

Why? Because there are a bunch of folks like us who like to wonder about parameters and other jargon and make an attempt to learn whatever we can. Of course, things needn't be explained or learnt to the fullest extent. Hence, we try to get a small part of what the journals actually convey. Not losing anything no? As long as one has the time and interest to discuss something, I don't see a reason to question the intentions.

Quote:

Originally Posted by audioholic

(Post 3805477)

Why? Because there are a bunch of folks like us who like to wonder about parameters and other jargon and make an attempt to learn whatever we can. Of course, things needn't be explained or learnt to the fullest extent. Hence, we try to get a small part of what the journals actually convey. Not losing anything no? As long as one has the time and interest to discuss something, I don't see a reason to question the intentions.

|

I fully agree and support. In fact I know quite a few DIY guys who over they years built up a an astonishing insight in how their cars work.

It's just a matter of interest, it is not rocked science or black magic. It is actually, pretty straightforward engineering. And there is a wealth of information available on line. And those thick manuals? most of the them can be found online as well these days, or you can at least buy them online.:) I know I have

Jeroen

Quote:

Originally Posted by audioholic

(Post 3805477)

Firstly, disregard calculated load value, since the calculations done are very random. So random that this parameter in my WagonR is dependent upon throttle position and commanded idle. So I can switch off the engine, floor the accelerator and yet the calculated load will remain showing some value.

What you can check is the absolute load or actual load PID if that's available. This will be more accurate.

Coming to EGR, the error you see is the behavior of the control system. It is constantly adjusting the position and making small corrections wrt the error in position. You should worry if the error percentage goes to a larger extent than such minute values.

|

Thank you audioholic. I am just getting to understand these parameters. Let me check if absolute load or actual load PID is available.

Quote:

Why? Because there are a bunch of folks like us who like to wonder about parameters and other jargon and make an attempt to learn whatever we can. Of course, things needn't be explained or learnt to the fullest extent. Hence, we try to get a small part of what the journals actually convey. Not losing anything no? As long as one has the time and interest to discuss something, I don't see a reason to question the intentions.

|

I agree. It is individual interest. There are folks who want to learn / understand and spend time. It also serves you well when you interact with the SA and mechanic at ASC.

Quote:

Originally Posted by a4anurag

(Post 3805287)

I tried to see what values my Swift ZDi gives for Engine Load parameter.

Here are the screen shots :

At 100 kmph (Without A/C): Attachment 1416582

At 100 kmph (With A/C): Attachment 1416583

So what load values your getting isn't right IMO. 30% is high. I am getting 16 to 18% at idle. Hope all electricals are OFF.

|

Comparing the load at a speed can be tricky because it fluctuates heavily based on the following.

- Whether the vehicle is climbing or descending ( even slight slopes can create huge variations in engine load. We might not even realize that we are on a slope because of the comparative slope of the terrain that we are on )

- Whether the vehicle is accelerating, decelerating or steadily maintaining speed with constant accelerator input.

If comparison needs to be done, it should be done on the same road on 2 vehicles using the same driver trying to maintain a constant speed on the same gear with fixed throttle input.

Quote:

Originally Posted by Jeroen

(Post 3805431)

All these idle loading numbers are off the wall. When an engine idles there is virtually no load. Idling cold or warm has less then marginal effect on the idle loading which is very low anyway.

|

Engine load is zero when descending with engine braking. ( like coming down a slope on 3rd gear without accelerator input ). To keep the engine on idle, there is indeed a load.

Quote:

Originally Posted by Jeroen

(Post 3805431)

Your typical AC would draw 3-5 horsepower max and that includes both the compressor and fan. So 10% is way off as well. Would be interested to understand how this kit calculates loading, because it cant measure it. It can only calculate it based on its input parameters.

Jeroen

|

If we assume that the torque at 800 rpms is 80 Nm, the power at that rpm is 9 HP.

15% of 9 HP is just 1.35 HP. So, it doesn't seem to be way off target at all.

Quote:

Originally Posted by pixantz

(Post 3805455)

I'm finding it hard to understand why are we wondering about parameters and other jargon when a trained technician or mechanical engineer is the apt guy supposed to be worried about this stuff. I mean, it's not like discussing congress bjp politics, no? These are highly technical details/ readings and I don't feel that just about anybody is supposed to understand them clearly. Believe me, those mechanical engineering journals are really thick and heavy. Just saying....

|

Not necessarily. If you know what happens inside the engine, it's easier for you to take any issues to a closure in a faster way. for instance, initial batch of Etios diesel had a software bug where the threshold for normal air intake was set very low, and the vehicle would fall into safe mode where there is a huge loss of power. The service engineer didn't have a clue of it. It's because I kept on insisting that the Fuel:Air ratio is not correct is when they found out the root cause and fixed it with a firmware update ( with the help of Toyota ). I'm not a mechanical engineer. I'm an electronics and communication engineer. And if there is any knowledge that I have today on mechanical engineering, it's through these discussions that I read and be a part of in team-bhp.

Quote:

Originally Posted by audioholic

(Post 3805477)

Firstly, disregard calculated load value, since the calculations done are very random. So random that this parameter in my WagonR is dependent upon throttle position and commanded idle. So I can switch off the engine, floor the accelerator and yet the calculated load will remain showing some value.

.

|

It's not the same for me. Maybe because it's showing absolute load. Not sure.

| All times are GMT +5.5. The time now is 20:01. | |