News

Complex car electronics: Solving check engine light issue on my Jaguar

Many OBD scanners will add some sort of text to the code they receive from the car. This is where our problem starts.

BHPian Jeroen recently shared this with other enthusiasts.

Finally, I managed to sort out the problem with the Jaguar. It makes for an interesting story of what kind of challenges one might encounter when diving into modern car electronics and wiring.

I thought I would spend a bit more time and provide some more detail on this particular problem. I believe it is exemplary of how these so-called "electronic" niggles might present themselves. And how difficult the troubleshooting can be. Even with many resources at hand!

Just to recap; During one of my trips to my boat, the Jag popped its CEL (Check Engine Light). The electronics on older cars, especially Jaguar can be a bit temperamental. So I carry my fancy Autel OBD scanner in the boot.

This is the so-called P-code that I found: P1646

One of the reasons older Jaguars might have some electronics issues is the quality of the wiring and various (plastic) connectors. Over time the insulation of the wiring becomes brittle and might break off, causing a ground issue. Same with the plastic connectors, they break. very often the little clip that is supposed to hold them in place simply snaps. Subsequently, the connector becomes a bit loose, water might find its way inside the pins, causing all sorts of continuity issues.

Whereas these sorts of issues are very easy to fix, finding them can be a royal PITA! Those of you who have followed this thread will have seen me fix several of these sorts of issues on the Jaguar and other cars, including my Spider.

These are not electronic faults at all. These are simple electrical faults, or mechanical faults at best. Because they can be very difficult to trace, you might come across cases where people start swapping ECUs. I have vented my opinion about swapping ECUs several times across several threads. It is important to understand there are no P-codes that suggest you need to swap an ECU. Not a single P-code, or other fault codes that have a definition SWAP ECU attached!

So swapping an ECU is always done as a last resort, but not before you have exhausted every other possibility first. Here is another thought, the Jaguar has 12 computers. When faced with engine/transmission/auto box issues, which computer are you going to replace? At least 3 or 4 of the computers are involved in the correct working of the complete power train.

Somewhere on this thread, I have shared an official Jaguar Technical bulletin on ECU swaps. Jaguar technicians swap computers and they get sent to Jaguar who checks them. The vast majority of these 'swapped' computers did not have any issues. It is a bit of sobering thought, that if, by and large, very well-trained and equipped, Jaguar Technicians incorrectly swap computers around, how the hell do mere DYI technicians trace and solve these sorts of issues?

Well, partly because our DIY time comes free, partly because we like to fiddle with our cars, partly because we are pretty much obsessed with our cars and partly because we have the internet. Now, the internet is a two-sided sword. There is a lot of technical crap out there. But if you have been part of the online Jaguar community for as long as I have, you know whom to trust. And of course, I am extremely fortunate to know my friend Raymond, probably the most knowledgeable guy on Jaguar X300/308s here in West Europe.

How is it that swapping computers sometimes does solve the problems? There are different reasons. When you pull a computer you will have to disconnect all the connectors. Depending on the car, you might have to deep dive under the dash, move wiring looms to get to it and so on. Just disconnecting a computer, and putting it back, swapped or not, might help, because disconnecting and reconnecting these electrical connectors might solve a dirt issue or a partly loose connector.

The same is true for messing about with wiring looms. It is a known troubleshooting trick. Keep tucking at wiring looms, near various connectors and so on, see what happens! It is pretty basic, but as I explained, the root cause of these so-called electronic problems is often very basic and has nothing to do with electronics as such.

Back to the problem at hand

So I had a CEL and a P-code. It is noteworthy, as you will see, that the engine did not go into reduced power mode. Almost all modern cars have something like this. When a serious problem in the Power train (engine, transmission) is detected it ensures the engine can only run at a reduced performance, so as to limit any further problems and/or damage.

Initially, I just reset the code with my Autel Scanner. Started the engine and it ran fine, CEL was out and I drove on. But after I made another stop and restarted it again the CEL and same P-1646 code popped up. That kept repeating itself. After resetting the CEL and P code would pop up after each subsequent second start-up of the engine.

I also performed a couple of hard accelerations in normal and fast mode. Timed them. My Jags still shot from 0-100 km/h in under five seconds!!

It is an important part of troubleshooting to try and observe as many irregularities in engine/transmission behaviour. That means noises, vibrations, warning lights, sequence of occurrence, under what circumstances does it happens etc.

In this case, every second start-up is relevant, because it most likely means we need to look at something that gets monitored and is allowed to show one fault during one cycle. When a modern engine is started all kinds of parameters are being monitored. Depending on which one, the computers will ignore false and or incorrect values for a certain time. Just to allow the engine to settle properly.

Once I got back home, I started to investigate properly.

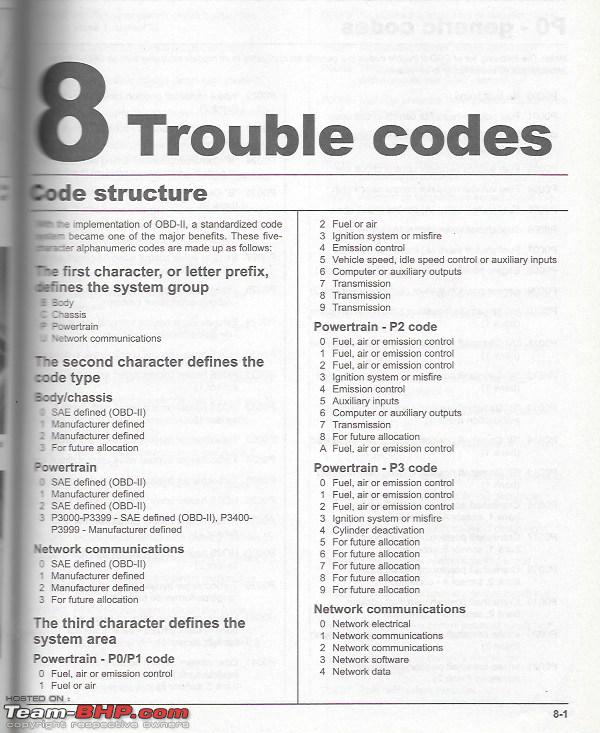

The first thing we need is some basic knowledge of OBD codes and OBD scanners.

Below you see an overview/structure of the various Codes your various computers in your car can throw at you:

(This is a page from my Haynes OBD manual)

So we have a P1646.

- P means we have a powertrain code

- 1 means it is a manufacturer-defined code

- 4 means it is an emission control-related code

If you have followed my various posts across TeamBHP you will notice I always advise members to get their engine codes read with a scanner that can handle "manufacturer-specific codes".

Most (cheap) scanners will only read the general or SAE-defined codes).

Whether you have a cheap or expensive OBD scanner they all do the same thing. It is your car's computer(s) that sends the actual code to the scanner. So the P1646 is generated inside the Jaguar computer and sent to the OBD scanner.

Many OBD scanners will add some sort of text to the code they receive from the car. This is where our problem starts. As long as it is a generic code, so something starting with P0xx, you can probably rely on the correct text being applied to the respective code.

But when you have a manufacturer-specific code, it becomes messy very quickly. Even my, not-so-cheap Autel OBD scanners get it wrong!! And my Autel scanner has a pretty comprehensive database. As part of setting it up, you need to choose the manufacturer, model, year and VIN number. So you would think they have a pretty elaborate kind of look-up table and logic implemented!

So to recap, if you have a code, manufacturer-specific or otherwise, the code itself is likely to be correct. But you can not rely on your scanner to tell you what the fault means!

About these P1xx manufacturer codes. They are what the name suggests. Try looking up a P1xx code for say a Jaguar and a BMW. For the same code, you are likely to see completely different meanings!!

But it gets more complex. Even within one manufacturer, or worse one model the same code can have different meanings depending on certain variables. (e.g. engine type)

So whenever I pull a code from my Jaguar it is back to my office and find out what that code might mean for my car.

I do have a lot of documentation, but not all. I also check the various Jaguar forums on P-code as well. Immediately it became clear that P1646 is a contentious topic in the X300/X308 community!!

In essence, P1646 on my Jaguar, a 2002 Super Charged version, means a problem with the secondary fuel pump. On earlier and or non Supercharged models P1646 means a problem with the upstream Lambda sensor on the passenger side (bank) of the V8.

But not everybody agrees with the above. Worse. I could not find a solution to the P1646 on a supercharged Jaguar at all.

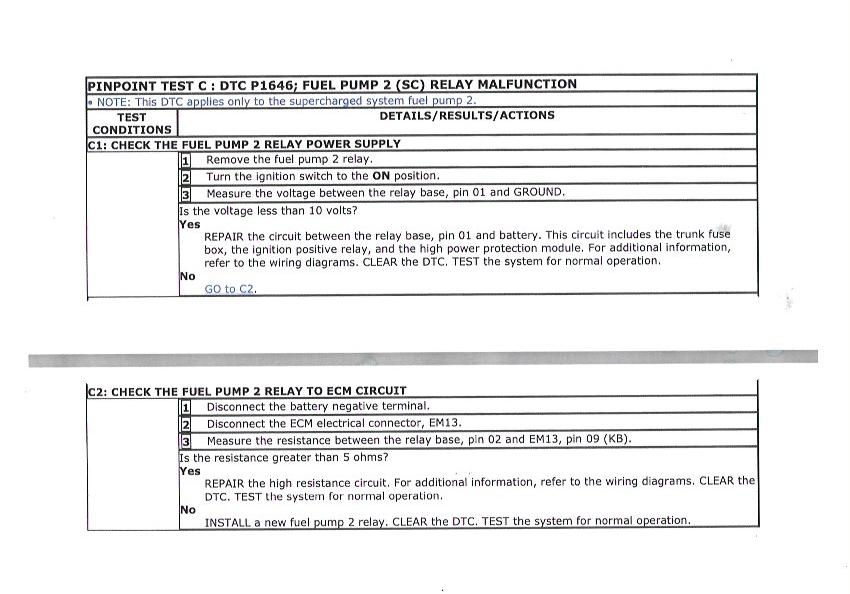

Let's have a look at what I found in my documentation:

But before I start testing, I like to understand how the system I will be testing is supposed to work. That is not always that easy to figure out, but with the help of the internet, some documentation and some tests as I will show you I got a fairly good idea.

Here is the wiring diagram that shows how the two fuel pumps are operated by two relays, controlled by the EMU. Very useful when you start doing electrical troubleshooting.

The secondary fuel pump kicks in, very briefly when you turn the ignition on. It helps prime the fuel system to the correct pressure. During normal driving the secondary fuel pump does not run at all. It only kicks in at (very) high engine loads. High revs with high power.

When I began to figure out the P1646 was related to the operation of the secondary fuel pump, and a simple relay was involved. Very first thing I did was to just swap the relay with another one. Did not solve anything. I did notice that when I pulled the secondary fuel pump relay, I would get the CEL and the P1646.

So next I just went through all the various tests described above.

Which involves testing for correct voltages at various terminals and measuring for continuity (lack of resistance) in the various wires going from the Jaguars computer (EMU) and the relay. The EMU sits at the front under the hood and the relay sits in the boot.

Disconnecting the correct connector from the EMU

The relay and fuse box in the boot. Notice the thin grey wire sticking into the relay socket? I used that wire to perform the continuity (resistance) test as mentioned above under C2.

I also injected 12 V directly into the fuel pump. I could hear it turn and fuel being pumped around the tank.

After a couple of hours of fiddling, I had not found anything out of the ordinary. Time for some more road testing. My Autel OBD scanner also has a live data function. So it can scan hundreds of different sensors, and parameters all over the car. So I took the Jag for another spin.

The first thing I wanted to check is whether the secondary fuel pump really kicks in under acceleration. Look at this, sure it does!

I also checked all available parameters. Based on various discussions on the internet I was particularly interested in the operation of the lambda sensors. My car has four, two on each side of this monstrous V8. One upstream and one downstream of the catalytic converter.

I looked at all the data and compared left to right, right to left but I could not detect anything abnormal. These are heated lambda sensors. So they have a heating element as well as providing the actual O2 measurement (as a voltage)

So all my tests and measurements brought no resolution as to the cause of this P1646 and CEL. As I mentioned, I did have a CEL but not reduced performance. As I dived deeper and deeper into the Internet and my documentation that was odd. Because with P-1646 on my Supercharged Jaguar, I should have also seen "reduced performance"? Confused, I certainly was by this time.

In the end, for lack of other options, I decided I was going to take a closer look at this blasted Lambda sensor. Sure enough, when I measured the resistance of the heater circuit I found it to be infinite!

Time to call super Jaguar specialist Raymond. As always Raymond gave me a very elaborate explanation. He never uses P codes or the sort of measurements from the Jaguar documentation. He has a very advanced Jaguar-specific diagnostic system. Which will tell him, immediately what the problem is and what else to check and to replace. I would love to own one. But it cost more than my Jaguar, so I doubt I will get Mrs D to approve such an expenditure.

Based on his experience, Raymond was 100% sure it was the Lambda sensor. He replaces some 40-45 of these annually!

He told me to remove it and send an image of the connector. There are dozens of different sensors out there. But the so-called connector code tells Raymond what sensor I needed. The connector code is the shape of the connector in combination with the various notches on its edge.

Getting a Lambda sensor out of its socket can be a bit of a struggle. I was relieved to get it out fairly easily. Albeit by using one of my large spanners with a 1-meter-long extension. These things are tight!

I had to remove the air filter intake filter housing, with the air mass flow meter and tubing to the throttle body. Simple job, two bolts, five clamps on the filter and one electrical connector.

Again, one of the clamps on the filter body broke off. Did I mention the cheap quality of Jaguar plastic! JW weld to the rescue as always.

The spannering itself was not all that difficult, once the air inlet assembly was removed.

You can clearly see the Lambda sensor sticking out, just above the catalytic converter.

Here we have the old sensor on my workbench, amidst endless Jaguar documentation.

I spoke to Raymond around 1500 hours. I send him the image of the connector by 15.30. And by 1600 hours Joke, Raymond's wife had dispatched the new Lambda sensor by courier to me!! That is outstanding service!

The next day it arrived around 10.00 o'clock. All the couriers and mailmen know, if nobody answers our doorbell, check the garage!! Because I am usually in my garage.

As per my usual, checking old and new. Although, the chances of Raymond sending an incorrect part are probably close to zero, if not actually zero!!

Put the new sensor in, and took the Jaguar for a spin. I am happy to report that I have driven over 500 km with the new Lambda sensor. No CEL, no P-codes.

It still remains a mystery to me and many folks on the internet what is going on here. There is no doubt that pulling the secondary fuel pump relay triggers the CEL and P1646 on my supercharged X308. There is substantial evidence out there in the shape of many official Jaguar documents that confirm, that my car P1646 is related to the secondary fuel pump!

Even so, the root cause of the CEL and P1646 was the heater in the Lambda sensor giving out.

As always, there were some folks suggesting to swap out the ECU or rather EMU as Jaguar calls it. But to them, I say what I always say. Statistically, the chances of anything being wrong with the ECU/EMU or any computer are extremely slim at best.

My best guess is still some errors in the Jaguar documentation. One of the problems we have is that there is a lot of Jaguar documentation about it. But not all, and you never know if you have the latest revision. Even on these old cars.

Obviously, there are a few known ECU troubles on come cars. But they tend to be well-known by the respective make/model community.

I am very happy with having solved this problem. Learned a lot too.

I hope this little story might help other members too, when discussing the intricacies of troubleshooting "electronic" problems on modern cars.

Check out BHPian comments for more insights and information.

.jpg)