| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  209,273 views |

| | #61 |

| BHPian Join Date: Sep 2010 Location: Mumbai

Posts: 294

Thanked: 1,273 Times

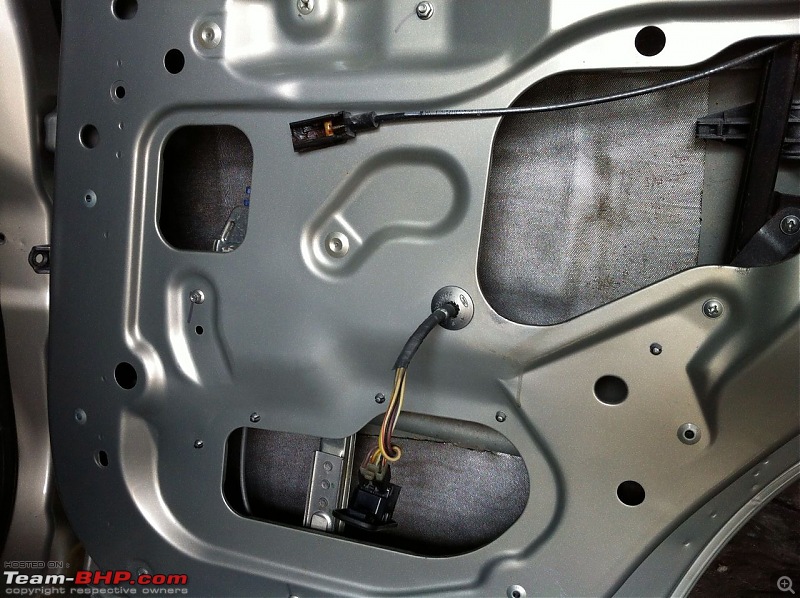

| Upgraded Brakes Upgraded Brakes After having completed the installation of the custom made exhaust and Weapon X ignition coil, the car was driven around for couple of weeks to get a better feel of the changes made and test the build for any problems. The car undertook 4 to 5 Mumbai – Pune runs and back. Along with these runs, the car was driven around both cities in all conditions that could be encountered. The car ran like a dream, smooth and responsive. The car is so good that Vikram is now thinking about buying a used Ford Fiesta to make it his own personal performance machine. He called me in the middle of the night after his first run, all excited and pumped up, asking if I know where to find one. However, these runs brought forth a rather vexing problem that has been plaguing the car since the day it was bought. The stock car has an Achilles’ heel. Right from the first Fiesta 1.4L, I had found the brakes to be weak and squishy. With the subdued power of 1.4L power plant this weakness does not come to the forefront and become apparent. When we bought the 1.6L the weak brakes became much more apparent. Don’t get me wrong, the brakes are adequate for the stock car, but this is an edge of the line case. Most people will factor the stopping power of the brakes into the driving experience and a few hundred kilometers of driving will embed the inputs into the subconscious decision making part of the brain. Like most people I too got wired to brake and their stopping power. I got so use to the same that I did not pay any attention to them other than an occasional thought in the passing that the car can do with better brakes. When my wife commented on the brakes I asked Vikram to source a set of Brembo brake pads, install them and bleed the brake lines properly. This improved things by about 10%. Other than that we simply lived with it and worked our driving around this chink in the armor. Therefore, while we were planning for the stage 1 modifications, we did not consider brakes as an area to be improved upon. We though we could leave it for stage 2 where we will install K-Sport or Brembo 4 or 6 piston caliper with larger ventilated and slotted discs along with rear wheel disc conversion. The other reason why we were planning for this change in stage 2 was the dreaded Parkinson’s Law; “Work expands so as to fill available resources”, had reared its ugly head up. As we worked on the details we found that the initial budget outlay we had planned for the build was running short and some things would need to be pushed to stage 2. During the runs between Mumbai – Pune it quickly became apparent that we had a major problem on our hands. While the brakes are barely able to cope up with an occasional hard braking situation, they were a downright disaster waiting to happen if they needed to be used in a more spirited situation. On couple of occasions when Vikram was in the seat he had over heating problems while coming down from Lonavala ghats. By the time he reached down the ghat, the brake pedal was touching the floor and the brakes were barely working. He came back and said “Sir, I cannot give this car to you in such condition. We will need to upgrade the brakes. Period!” This got me thinking about what to do. I am sure that once my wife gets to try her hands on this car, she is going to insist on making it her regular car. She is a very aggressive driver (and a good one). There was no way I could have her driving around with such brakes. I discussed my problems with Vikram. The crux of the matter was that there was no money right now to invest in a set of K-Sport or Brembo brakes. We discussed the problem at length. As most of the money had already been spent on procuring parts as planned initially there was very little left in the kitty to add anything major that was not already planned for. I also pointed out to him that there was little point in upgrading only the brake lines as the whole braking system was inadequate for the amount of power we were generating. Vikram asked for couple of days to think things through. He came back few days later with a proposal to upgrade the brakes. He proposed that till we do the stage 2 changes he would source a set of larger discs and caliper from another car model and install the same. This should solve the problem in the near term and would be relatively cheap. I was very hesitant to consider the proposal. Right from my childhood I was taught that engineering solutions that are temporary ‘fix’ is just that; ‘temporary’. They are never good design and will not last and almost always are bad for the health of product. No offense to anyone but ‘jugaad’ concept is something that only delays the problem, and does not really deal with the problem. I discussed my apprehensions with Vikram. I told him that I am not looking at this as a temporary solution, if implemented; it should be good enough to last the lifetime of the car. It should not look crude and makeshift. And most importantly, it should be extremely reliable. Vikram assured me that the implementation would be like OEM fitting. There would be no unnecessary use of spacers and washers just for the sake of getting the correct mounting tolerances. Nor would there be any make shift mounts. Once he assured me, I gave the go ahead for the mod. The stock car has a 258 mm diameter rotor and an single piston caliper setup. Interestingly, the Ford Fiesta Mk5, on which this car is based has an identical brake setup, however the car is a hatchback with a much lower kerb weight of 976 kgs. This car has kerb weight of 1130 kgs due to the added boot design.  Stock Disc & Single Piston Calliper Setup   Note the Brembo Pads. Not very effective. Still had life of about 30,000 kms.   258mm Stock Disc. Identical setup as Ford Fiesta Mk5 Hatchback.  Vikram proposed using was a 278 mm diameter rotor and a correspondingly larger diameter single piston caliper setup. That’s full 20 mm bigger disc. This along with the larger diameter caliper pistons would surely take care of the braking woes suffered by the car.  Upgraded 278 mm Disc.  Installation of a bigger disc and caliper are not bolt on and comes with its own set of complications. The stock mounting brackets points are no longer good enough to mount the caliper as the disc size and the caliper piston are bigger and the mounting position on ‘x’ and ‘y’ axis shifts due to the increase in disc dimensions. It is quick and tempting to create a mounting plate to take care of the ‘y’ axis and use thrust washers and spacers to take care of the ‘x’ axis. However, where breaking forces are concerned stiffness along the ‘y’ axis of an assembly matters (‘x’ axis is floating as it needs to align itself to the disc) and use of thrust washers and spacers creates an overall weak assembly, which is prone to flexing along the ‘y’ axis under heavy braking situations. Vikram took very careful dimensions by first mock mounting the new disc and caliper and then designed a one-piece dog bone mounting plate that took care of mounting on both the axis. The dog bone was first designed on Siemen’s Solid Edge 3D modeling software before being machined from a solid billet of mild steel on a VMC machine. In case you are wondering why we have used mild steel instead of high carbon steel or even exotic titanium (as has been done on my bikes), the complete stock mounting assembly is in mild steel. For the time being we do not see any reason to go down this road when there are plenty of other things to do. The result of all this effort is a mounting system that is as good if not better than the stock OEM system.  Upgraded 278mm Brake Setup. As good as OEM. The car was taken out for a spin and there was an immediate difference in the braking power and initial bite. The brakes are now sensitive and starts gripping the disc as soon as you give a light touch to the brake peddle. Off hand I would say that braking power has increased by 35% to 40%. We have now covered over 1,000 kms with the new brake setup and it works flawlessly. Once the custom made steel braided brake lines are installed the brakes should be even better. Bottomline: We cured a perennial problem that has been facing this car since the day it was bought. The solution now allows us to make the most of the increased power output. Next: Car Body Work. Last edited by PratikPatel : 27th June 2016 at 12:53. |

| |  (17)

Thanks (17)

Thanks

|

| The following 17 BHPians Thank PratikPatel for this useful post: | anachronix, blackwasp, deetjohn, frankmehta, jprash75, kutlee, NiXTriX2004, Rehaan, rosaf, S2!!!, somspaple, suhaas307, swiftnfurious, Teesh@BHP, tharian, theexperthand, Viju |

| |

| | #62 |

| Senior - BHPian | Re: Project ST: Ford Fiesta 1.6 Duratec A much required upgrade on the previous generation Fiesta, the amount of feedback from the brakes during spirited driving was always a downer. A few questions! 1. Is it only the front discs that were upgraded? 2. Have you considered testing the brake bias after the upgrade? You might face over-steer during spirited driving around corners. The car can fishtail on a straight line braking as well if the bias is too much to the front. 3. I might have probably missed it, your's is a non-ABS car? |

| |  ()

Thanks ()

Thanks

|

| | #63 | |

| BHPian Join Date: Sep 2010 Location: Mumbai

Posts: 294

Thanked: 1,273 Times

| Re: Project ST: Ford Fiesta 1.6 Duratec Quote:

1. Yes, currently only the front discs have been upgraded. For stage 2, we have identified the parts required to do a full all wheel disc conversion along with 4-piston caliper upgrade in the front (its become one of our top priorities). 2. Yes, we have tested the car for brake bais after the upgrade. The drums are surprisingly good at their job. As a matter of fact, comparatively the drums are far better at their job than the stock front discs. There is slight over-steer during down hill runs, otherwise on straight roads it is not noticeable, its there but wonít come to the forefront till the car is taken to track conditions. However, we aim to address the issue by sourcing a complete 1.6S steering system (will have to study it further to see if it will work and solve the problem rather than create new issues). Under very hard braking the car stops in a straight line. This again is due the extra kerb weight and the drums performing well enough to keep the car inline. 3. Yes, my car is not equipped with ABS. | |

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank PratikPatel for this useful post: | anachronix, samaspire, swiftnfurious, theexperthand |

| | #64 | |||

| Senior - BHPian | Re: Project ST: Ford Fiesta 1.6 Duratec Cool! That will be a great upgrade for the Fiesta. Quote:

Have you got the upgraded tires on the car already? Only the steering rack is different from the normal Fiesta in the S. If you can get access to the child part I think you could save some bucks. The column is the same. The steering rack in the S improves the feedback/feel on the steering a lot and reduces effort in steering when running wider tires. Not sure if this aids the stability under braking in any way. Quote:

Quote:

| |||

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank anachronix for this useful post: | motorpsycho, PratikPatel |

| | #65 | |

| BHPian Join Date: Sep 2010 Location: Mumbai

Posts: 294

Thanked: 1,273 Times

| Re: Project ST: Ford Fiesta 1.6 Duratec Thanks for the inputs on the 1.6S steering rack. It's really helpful. We have still not changed the tyres. We will do that after the car is painted. Any idea if the ABS unit is independent from the EEC system? If it's independent then it becomes easier to install. Quote:

| |

| |  ()

Thanks ()

Thanks

|

| | #66 |

| BHPian Join Date: Sep 2011 Location: Goa

Posts: 969

Thanked: 1,297 Times

| Re: Project ST: Ford Fiesta 1.6 Duratec |

| |  ()

Thanks ()

Thanks

|

| | #67 | |

| Senior - BHPian | Re: Project ST: Ford Fiesta 1.6 Duratec I can check with my folks and come back to you Pratik. From what I know, it can be done. I will get you more details on this and share over PM! Quote:

| |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank anachronix for this useful post: | akshay380, PratikPatel |

| | #68 |

| Senior - BHPian Join Date: Mar 2008 Location: Mumbai

Posts: 1,910

Thanked: 10,138 Times

| Re: Upgraded Brakes |

| |  ()

Thanks ()

Thanks

|

| | #69 |

| BHPian Join Date: Sep 2010 Location: Mumbai

Posts: 294

Thanked: 1,273 Times

| Re: Upgraded Brakes

Work is on going. Unfortunately Vikram's dad had suffered a transient stroke so work had to be suspended for a few days, however we are back on track. Will start updating the thread in 10 days time. |

| |  (6)

Thanks (6)

Thanks

|

| The following 6 BHPians Thank PratikPatel for this useful post: | akshay380, frankmehta, Rehaan, rosaf, S2!!!, swiftnfurious |

| | #70 | |

| Newbie Join Date: Nov 2005 Location: Mumbai

Posts: 16

Thanked: 12 Times

| Re: Upgraded Brakes Quote:

A fundamental question, since you've done a fair bit of research in unearthing why the Fiesta's brakes were, by design, inadequate in the first place (increased kerb weight due to the Mk5 hatch being converted to a sedan for India) - What contributes more to braking efficiency - the front discs - or the rear drums - of front-wheel-drive car? Would upgrading the rear drums be a more cost-effective (and less engineering-intensive) solution? Mod Note : Please quote ONLY the relevant bits of a post. Quoting a full, long post inconveniences our mobile readers. Thanks! Last edited by Akshay1234 : 3rd August 2016 at 20:52. Reason: Removing the complete quoted post | |

| |  ()

Thanks ()

Thanks

|

| | #71 | |

| BHPian Join Date: Sep 2010 Location: Mumbai

Posts: 294

Thanked: 1,273 Times

| Re: Upgraded Brakes Quote:

The first law of motion; "An object in motion continues in motion with the same speed and in the same direction unless acted upon by an unbalanced force". In this case as the car is moving at a particular speed and in a particular direction, to slow or halt the car we need to apply a unbalancing force to overcome the motion of the car. When we apply the unbalancing force the second law of motion comes into play; " The rate of change of momentum of a body, is directly proportional to the force applied". In other words the faster you want to stop, the more force you will have to apply. Thus when we apply force as per the first and second laws of motion, the third law comes into play: "For every action there is a equal and opposite reaction". Thus when braking forces are applied, the car tries to resist the braking force by trying to continue its forward motion, whereas the braking forces try to slow the car down by resisting the forward motion. Now lets say that a front engine/front wheel drive car has a weight bias of 55/45 front/rear. In this tug of war, when the braking forces are applied the weight bias of the car changes, with weight shifting from the rear to the front as the car tries to resist the braking force to keep moving forward. This weight transfer suddenly (depending upon how much force is applied) unloads the rear wheels making them specially sensitive to wheel locks, whereas the added weight in the front makes the front wheel resistant to wheel locks (they will eventually lock with enough force being applied). Even if the car had a 50/50 or a 40/60 weight bias, while braking weight will move from rear to the front to a significant extent. Due to the above scenario the front wheel brakes do most of the heavy lifting as far as slowing down cars/bikes are concerned. This is the reason that you will find larger disc systems in the front vis-a-vis rear. Very few cars (read 'high performance') have discs that are of equal size at the front and rear. As for your second query; the answer is no. Conversion from drum to disc in the rear is a major upgrade and would be much more complicated than what we have currently done with the front discs. Also as @anachronix rightly pointed out there is a fine balance between the front and rear braking systems. It is interesting to note that for non ABS Fiesta, Ford has provided a brake pressure reduction valve for the rear break circuit in order to provide a workable front/rare brake bias. Last edited by PratikPatel : 4th August 2016 at 16:49. | |

| |  (17)

Thanks (17)

Thanks

|

| The following 17 BHPians Thank PratikPatel for this useful post: | AbhisheKulkarni, aqualeo2040, deetjohn, humyum, jprash75, MaddyCrew, neil.jericho, pavanmadhini, petrolhead_neel, Rehaan, S2!!!, SteveSR1, suhaas307, tharian, theexperthand, VinNam, vishal.joshi |

| |

| | #72 |

| Newbie Join Date: Jan 2015 Location: Chennai

Posts: 15

Thanked: 27 Times

| This comment alone is worthy of being a chapter in a physics textbook. I know the mods look down upon comments that don't advance the thread significantly, but some one had to say this... This thread rocks! |

| |  (1)

Thanks (1)

Thanks

|

| The following BHPian Thanks luckystryker for this useful post: | akshay380 |

| | #73 | |

| Newbie Join Date: Nov 2005 Location: Mumbai

Posts: 16

Thanked: 12 Times

| Re: Upgraded Brakes Quote:

P.S. Not that it matters now, but what I meant when I said "upgrading the rear drums" - was using a drum-upgrade kit comprising of a larger bore cylinder - and NOT changing the rears brakes to discs. Someone told me that was a better approach to compensating for the loss of rear bias - under extreme braking - in front-wheel drive cars. Came across a few articles on this subject which were worthwhile reads for the uninitiated like yours truly  http://stoptech.com/technical-suppor...brake-upgrades http://www.mpbrakes.com/techtalk/dru...or-gm-and-ford | |

| |  ()

Thanks ()

Thanks

|

| | #74 |

| BHPian Join Date: Oct 2012 Location: pune

Posts: 132

Thanked: 178 Times

| Re: Project ST: Ford Fiesta 1.6 Duratec Awesome Job Pratik Sir, You have paid such attention to detail.Inspiring and Mind blowing  Cant wait to know and see the end result of your Fiesta. I am myself thinking of getting used 1.6 Fiesta now. |

| |  ()

Thanks ()

Thanks

|

| | #75 |

| BHPian Join Date: Sep 2010 Location: Mumbai

Posts: 294

Thanked: 1,273 Times

| Car Body Work and Painting Car Body Work ĎRustí is a dreaded word in the world of cars and bikes. After dust it is considered to be the worst enemy of the automobiles and is detrimental to the health of the car. It can create various problems ranging from making the car look bad to reaching a stage where it can cause metal fatigue breakdown and be life threatening (as metal corrodes it weakens). So why does rust form? Most people will say due to water and they will be right too. However, there are other factors to consider. Rusting is a product of an electrochemical process called corrosion. To create rust (Iron Oxide) three things need to be present; anode, cathode and electrolyte. The carís body acts as anode and cathode and water acts as an electrolyte. Now consider this; not just water in its liquid form but also in its diffused form i.e. moisture, will act as electrolyte. Therefore, even if the car has been covered it can develop rust. To add further misery, if there is salt content in the moisture it will develop rust at much faster rate. By living in Mumbai where it rains four and half months a year and humidity during these months can be as high as 95% I was not helping my case (year round average is 75%). There is also the fact that I live about 3 kilometers from the sea shore which means that there is some amount of salt in the air. Add to all of the above, I donít have covered parking space. So the car is out in the open 365 days a year and exposed to all weather elements. There are couple of other habits which further exuberate the problem. The habit of washing a car daily is one of them. I have tried to explain this one to my wife on a number of occasions but believe me when I say it is as lost a cause as it is arguing with your better half on the need to change clothes twice and thrice a day when you are on a vacation (donít ever put Ďthe heavy bag lifting has to be done by youí argument). The daily washing of the car done in most residential buildings in Mumbai as a daily morning ritual is a recipe for rust formation. The other reason is parking the car under trees. Yes, you read it right, parking under trees. Before I go in to the reasoning, how many people have notice that car designers have incorporated water draining and management systems into the car body? Water is an unrelenting and incessant force. Just keeping water out of the cabin is major challenge and requires some intelligent designing to ensure water it taken away from the nooks and crannies before it collects in enough amount to force it self through the seals. The complicated body shapes of todayís cars do not help the cause. To know how water is managed, take a look at the doors of your car. When you look at the bottom of the door you will see 2 or 3 small square or rectangle orifices. These are water drain orifices. Water, which hits the window glass and flows down will not flow its entirety on to the door and down. Some of it will collect at the window bottom trim seam and leak through into the door. Such water is drained out through these orifices. For another example, open the boot of your car, look at the bumper under the rubber seal trim at the bottom, you will find small rectangle shape orifices. These again are water drain orifices. Another example is the front windshield cowl. This cowl has a grated design and many may feel they are a pain to clean. Open the hood of your car and see how the 2 ends of the cowl are shaped. You will notice that they are shaped like funnels. The job of the cowl is to collect all the water that falls on the windshield and flows down to the bottom and channel it to each end of the engine bay and let it fall under car, thus ensuring that no water ever reaches the engine bay. Now coming to the parking under the trees part; the worst possible tree to park under is the gulmohar tree. The tiny leaves of this tree have a tendency of falling on to the car and then slipping right between the windows, windshields and the rubber seals. Once they enter inside the doors and also collect in the windshield cowl, the leaves collect and coagulate into a solid mass blocking drain orifices. Water collects in the doors and windshield cowl and other orifices and the corrosion begins in earnest. When we decided to do the bodywork and the painting we thought we had a general idea about the amount of corrosion there was. It was estimated that to bring the car back to really good condition would require about 10 days. However, we were in for a rude shock. There was so much corrosion in the car that it took almost a month to complete the bodywork. You can see from the before and after photos that Vikram has done some really good work to restore the car.  Leaves block front windshield cowl drain channel which overflows water on to the front suspension mounting plate. Water collects on the mounting plate and causes corrosion.    Block water drainage holes started rusting and the damage inside the doors while not visible is extensive.  The car ready to be degrease and prepared for application of base coat after body work.  One of the doors after body work and filler application.  The window edges were also badly rusted. All redone. For painting we wanted to only the best materials and therefore we selected to use Standox exclusively. The filler, thinner, basecoat, paint, hardener and clear coats are from Standox and the high definition polish is from Autoglym. All other consumables were sourced from 3M. Standox officials were consulted on the recommended system for best results. They provided and discussed in great detail best system to maximize results. They provided formulation with exact ratios of various ingredients and method of application. A digital scale was used to ensure an exact ratio of ingredients was obtained. The bodywork was completed the car was thoroughly cleaned and degreased in preparation for painting. All blemishes were corrected with filler and ground with 3M emery papers. A coat of basecoat was applied and a through examination of the body was carried out. Any blemishes further identified were dealt with filler and ground. A coat of paint formulate was applied and allowed to dry. Once again any blemishes found were dealt with filler and ground. Once we were satisfied with the results of the initial foundation of filler, basecoat and paint, 2 additional paint coats were applied and with allowance for drying between the coats. After we had finished the painting a through inspection was carried out to find any defects. After the inspection, 2 clear coats was applied and allowed to dry.     The car is currently undergoing polishing with Autoglym High Definition Polish. The current photos due to their low resolution do not do justice to the paint job. We will post high definition photos once the car is ready. |

| |  (17)

Thanks (17)

Thanks

|

| The following 17 BHPians Thank PratikPatel for this useful post: | Blow Horn Ok, CGB, deetjohn, Dennis, frankmehta, Karthik1100, Leoshashi, NiXTriX2004, Rehaan, S2!!!, sai_ace, somspaple, suhaas307, sumeethaldankar, theexperthand, Vysakh, wbd8779 |

|