Team-BHP

(

https://www.team-bhp.com/forum/)

-

Post-War

(

https://www.team-bhp.com/forum/post-war/)

Having had a chance to interact with Christopher whilst driving from Bangalore to Hyderabad in a Buick, we had many hours of car restoration talks.

I was impressed by his dedication and very pleased to see this lovely Daimler coming to life again in a systematic manner.

No short cuts for Christopherclap:

Having completed the front-end of the chassis, the next section which is the center part is being attended to.

Since the floor is wood, there is very easy access to the whole chassis.

Chris, demonstrates access due to the gaps

Cheers

KPS

Great restoration KPS!! I have heard that Chris is a legend. Do you have any thread on his works or details about him?.. I've heard he has achieved so much at such a young age...

Quote:

Originally Posted by car love

(Post 4343336)

Great restoration KPS!! I have heard that Chris is a legend. Do you have any thread on his works or details about him?.. I've heard he has achieved so much at such a young age...

|

I am indeed fortunate the have Chris working on my car. His detailing and commitment to the restoration is outstanding. He has the ability to partner with specialist and give you the best solution.

I had covered his restoration of the Gold Diamler, as seen

here

Updates of my car is that, there has been some delay on account of certain spares, which seem to be difficult to find, even in UK. However, we are getting some solution now. Wanted the car to progress before, I awaken this tread again

Cheers

KPS

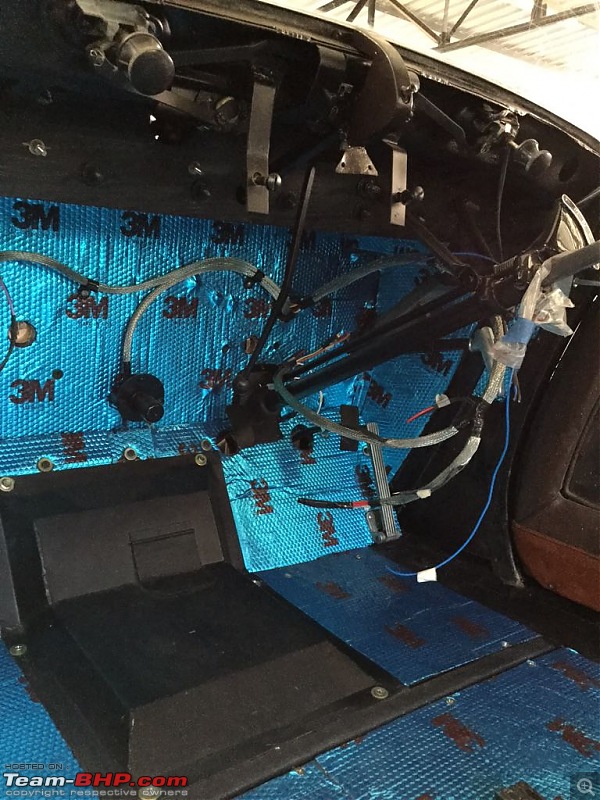

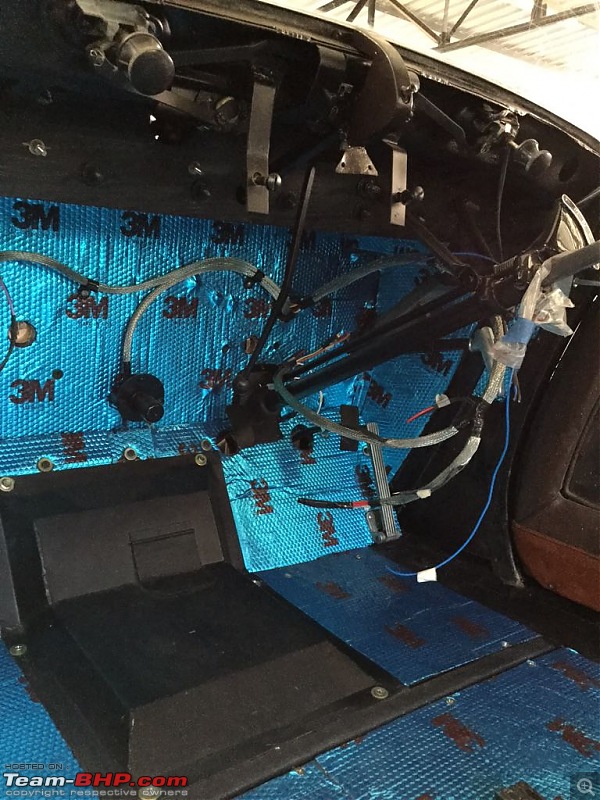

The chassis, suspension and wiring has been completed. The goal is to make the car more safe, reliable and so we have done some practical upgrades.

Seen in the picture is the under chassis. Originally the car came with a sound damper in the under chassis. This was made of cotton wool, jute cloth and tar pitch as a fire retardant. We undid, this as we thought that this was risky to retain.

The completed chassis is seen. Chris takes me through the work done.

We have changed the wiring from positive earth to negative earth. This is a safer option. New wiring was done.

You can also see the 3M material used to retard heat in the cabin and also damp the sound from outside

We will start on the tinkering work from Feb'18. We have to work on the body alignment and take car of the minor rust. Once this is done, we will do the painting and upholstery. The parts for the engine are expected to arrive by April/May'18

Cheers

KPS

Quote:

Originally Posted by KPS

(Post 4362465)

You can also see the 3M material used to retard heat in the cabin and also damp the sound from outside

Cheers

KPS

|

Great progress, Would you please elaborate more about the 3M, like the thickness, cost involved and durability etc.

Quote:

Originally Posted by KartikeyaL

(Post 4364037)

Great progress, Would you please elaborate more about the 3M, like the thickness, cost involved and durability etc.

|

This is basically a Butyl rubber with aluminum product for reduction of Noise, Vibration, Harshness (NVH) in cars, developed by 3M. This is very pliable and takes the shape of the car body for a good tight fit. By the nature of insulation material used, it does reduce the thermal impact too.

On my next visit to the workshop, will try and get more details.

Thanks

Subbaiah

Lucid and pertinent as always, Subbaiahji! Looking forward to the rest of the work done record. Though it is unlikely that I will ever need to venture into these waters of car restoration, it is very heartening to know that we have craftsmen of Chris' caliber in the country now.

Are you planning to use the 3M material on the under-body areas too instead of the original material?

Regards,

Shashanka

Quote:

Originally Posted by shashanka

(Post 4365739)

Are you planning to use the 3M material on the under-body areas too instead of the original material?

Regards,

Shashanka

|

Thanks Shashanka for your comments. We have used Marine Ply for the wood work at the bottom. Will just paint it to make it durable.

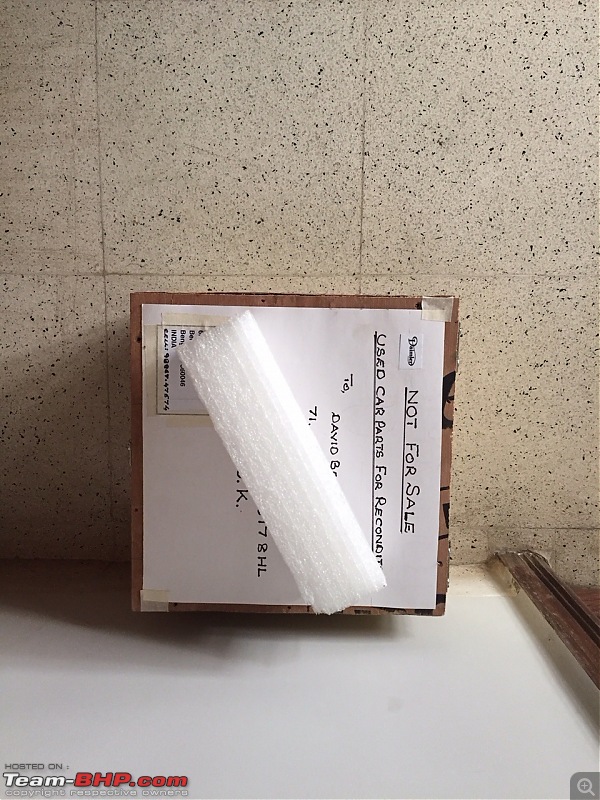

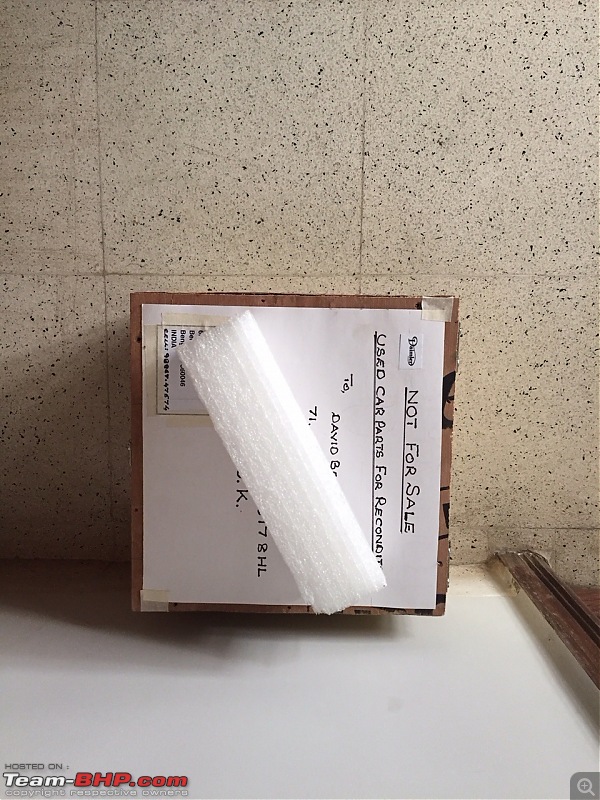

In the mean time, I shipped through DHL Courier to the UK, the Harmonic Balancer for reconditioning , Main Bearings for 10+ rework and one piston to make 10+ size piston rings set. We made a wooden box from plywood, so as to secure the parts for shipment. The parts were accessible as it had to be inspected prior to courier and for UK Customs. Luckily no customs for used parts going for reconditioning.

The parts were tightly packed.

Ready for despatch. Even though the weather in the UK was very bad, the same was delivered in 36 hours

Meanwhile, I have start to collect the other parts for the engine rebuild. The Big End Bearings, Complete Gasket Set, Timing Chain, etc has been procured.

Cheers

KPS

Quote:

Originally Posted by KPS

(Post 4366312)

Thanks Shashanka for your comments. We have used Marine Ply for the wood work at the bottom. Will just paint it to make it durable........In the mean time, I shipped through DHL Courier to the UK, the Harmonic Balancer for reconditioning ,

Cheers

KPS

|

This is marvelous! - thanks again, KPS (and Chris of course!) for this surfeit of information & details on a subject so close to the heart! A pity that I can't indulge this passion, but no matter - it is now only a matter of winning that Derby!

In the interim, thanks to wonderful people like for giving us this rare treat.

Regards,

Shashanka

As we wait for the engine parts, we have commenced to tinker the car. The primary focus will be on the alignment of all the panels.

Over the years, the door and window seals had hardened and lost their sealing abilities. This must have lead to water accumulation at the bottom parts, when washing the car or in the rains. Though the rust was very minor in nature, we decided to attend to it with a long term view.

The car was completely stripped and tinker start to work from one section to another.

The front door post tinkering and initial alignment.

The rear stepney cover which house the number plate needed some work and the bottom half had to be replaced.

Rear door is work in progress.

Cheers

KPS

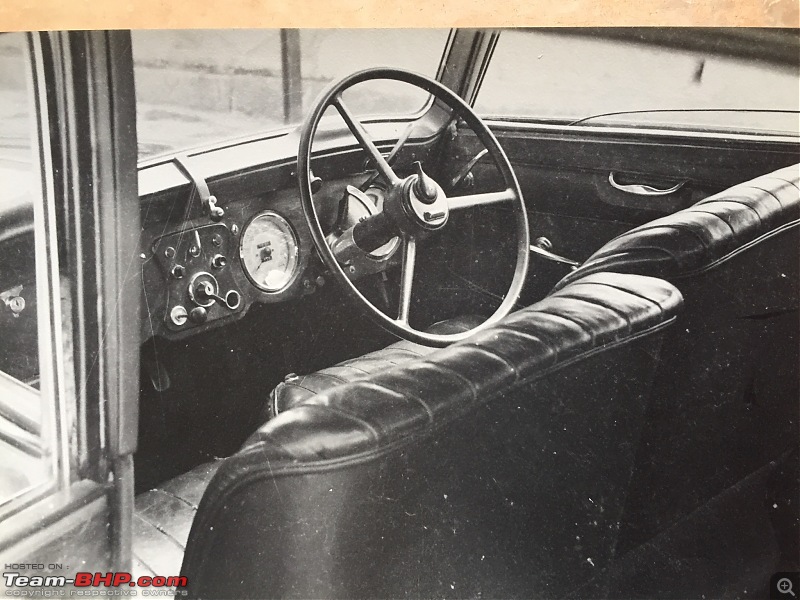

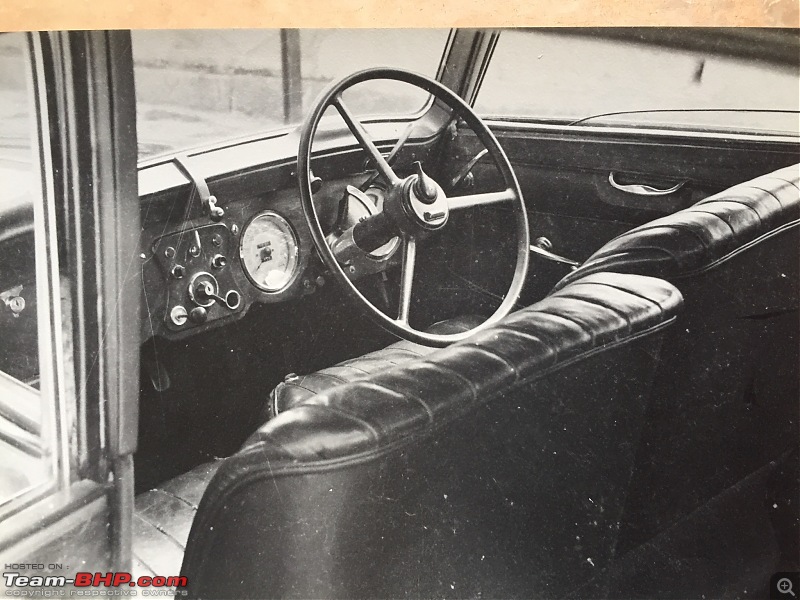

Sripathi has been kind enough to provide me some old pictures of the Daimler.

No idea as to when these pictures were taken

This appears to be period pictures, probably post 1957, under the new ownership

Cannot recognize this place

This picture is at Indian Institute of Science in front of Jamshedji's statute

Parked in from of Attara Kacheri, which is now the High Court of Karnataka

Cheers

KPS

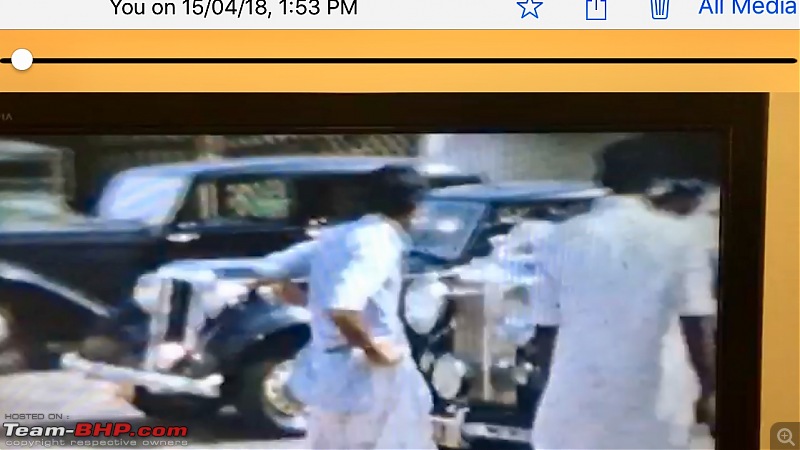

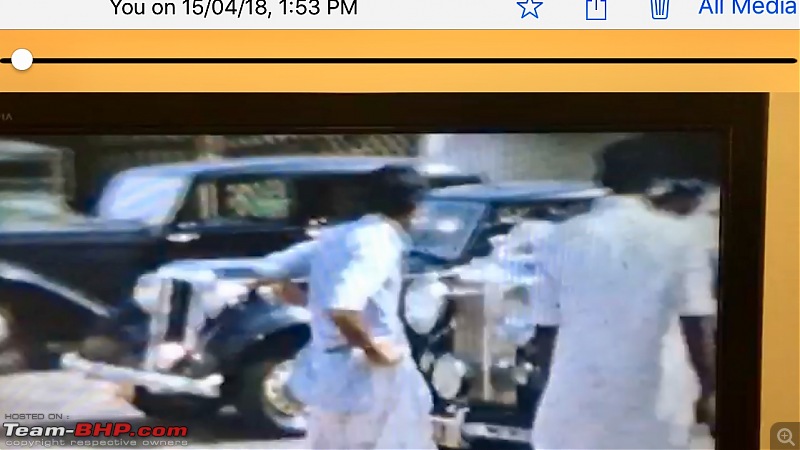

Want to share some very exciting news!

The grand nephew of Maharaja Jayachamarajendra Wadiyar, shared with me a video taken in the 1950's of some events of the Mysore Maharaja.

In the video there is a small section on Dasara events showing the Maharaja offering prayers to some of his cars as part of the rituals.

Further on in the video, there is a some function where we see 3 Rolls Royce Silver Ghosts being driven and amongst the cars in the background is my Daimler DB 18.

Here is a screen shot of the video with my car! Sorry for the poor quality but we are working to digitize this and get better video and picture quality.

It appears that the original colour combination was black and cream. This was changed to black and yellow under the next owners, at some point.

All the cars in the video were sporting red Mysore plates! We get to see together in the distance the Dharmasthala DE36, Rolls Wraith and the DB18 sporting red Mysore plates, but we cannot make out the number!

Here is a Silver Ghost "Mysore 45" in the same video

Hopefully once we clean and digitize the video we should have more clear shots!

Cheers

KPS

Has been to the workshop yesterday. The tin work is almost coming to an end. The next phase will be assembling all the panels and check out the alignment of complete body. Once this is done, we send the car off to paint.

The rear will always be a mystery. The tinker is very clear that the car has never been rear ended at any point of time. However, the rear glass was plexiglass and we need to tap the boot door a bit, to align. My guess is something must have fallen on the car causing minor damage and breaking its glass. Nothing major though.

However the rear glass is a bit of challenge as it is slightly curved. Hence we are making a mould in fibreglass to cast a new glass for the rear window.

Aligning the panels

The trim under the door was made and fitted for inspection. This is now ready for chrome

Cheers

KPS

Great progress KPS!! Where do you plan to do the chrome/electro plating? The so called "best" guys Vijaylakshmi is atrocious. I hope you are not headed that way. They wasted my money..Cheers

| All times are GMT +5.5. The time now is 15:56. | |