Team-BHP

(

https://www.team-bhp.com/forum/)

-

Post-War

(

https://www.team-bhp.com/forum/post-war/)

Quote:

Originally Posted by KPS

(Post 4473432)

|

Way to go, KPS! This is the least those chaps could do! It is wonderful that today our country too can boast of professional, painstaking restoration of the kind that you have undertaken.

Waiting for more, as and when.......

Regards

The problem with cars which were produced in low numbers is that some parts are very difficult to get. The main bearings set are one such critical item. Needed 0.010" main bearings, but these are almost impossible to get.

Sent the standard ones taken out of the car, to a specialists shop in UK for machining. Here is a picture of the redone main bearings, ready to be shipped back to India.

Cheers

KPS

Quote:

Originally Posted by KPS

(Post 4481552)

The problem with cars which were produced in low numbers is that some parts are very difficult to get. The main bearings set are one such critical item. Needed 0.010" main bearings, but these are almost impossible to get.

Sent the standard ones taken out of the car, to a specialists shop in UK for machining. Here is a picture of the redone main bearings, ready to be shipped back to India. Attachment 1809863

Cheers

KPS

|

Sir,

I can understand that machining can remove scratch marks caused by abrasion but how are you going to Compensate for the wear of bearings unless it replaced by next under size and also crankshaft grinding.

Quote:

Originally Posted by ARUN.V

(Post 4483512)

Sir,

I can understand that machining can remove scratch marks caused by abrasion but how are you going to Compensate for the wear of bearings unless it replaced by next under size and also crankshaft grinding.

|

The main bearings on removal from the engine, were found to be at the standard size only. This is the first time that the engine is being opened up.

Since we could not get new bearings for the next size, these bearings removed from the car, were sent to UK to be machined to the next size only.

Hope this clarifies

Thanks

KPS

Quote:

Originally Posted by KPS

(Post 4483593)

The main bearings on removal from the engine, were found to be at the standard size only. This is the first time that the engine is being opened up.

Since we could not get new bearings for the next size, these bearings removed from the car, were sent to UK to be machined to the next size only.

Hope this clarifies

Thanks

KPS

|

Though It is not clear to me , what I would assume is that they have a process where the material is built up on the worn bearing shells to bring it to the original standard size.

Quote:

Originally Posted by ARUN.V

(Post 4483989)

Though It is not clear to me , what I would assume is that they have a process where the material is built up on the worn bearing shells to bring it to the original standard size.

|

Essentially what you are saying is the process

The following is from a good friend who is a restorer based in Dubai (KPS, you know who :))

"Likely these bearings like rest of the bearings of that period would be made of white metal, to which new white metal can be melted on to the (old) shell and when cold it can be machined to size required.

I have done this in India long ago in 1970s on 1140 KW Skoda generators, which of course is huge in size.

The same can be done on automobile bearings as well. The Crank Jouranals will have to be mirror finished with good lubrication as otherwise this white metal will scrape on any rough surface and cease the engine.

I am sure this engine is a low RPM engine and probably long stroke"

Hope this clears your doubt in this regard

Best Regards & Drive Safe

Ram

Quote:

Originally Posted by r_nairtvm

(Post 4484594)

Essentially what you are saying is the process

The following is from a good friend who is a restorer based in Dubai (KPS, you know who :))

"Likely these bearings like rest of the bearings of that period would be made of white metal, to which new white metal can be melted on to the (old) shell and when cold it can be machined to size required.

I have done this in India long ago in 1970s on 1140 KW Skoda generators, which of course is huge in size.

The same can be done on automobile bearings as well. The Crank Jouranals will have to be mirror finished with good lubrication as otherwise this white metal will scrape on any rough surface and cease the engine.

I am sure this engine is a low RPM engine and probably long stroke"

Hope this clears your doubt in this regard

Best Regards & Drive Safe

Ram

|

It is now clear to me.

Actually it is rebuilding a bearing of which machining is only a part of the process , if Iam not wrong.

Happy to note that you have done this as early as 1970s

Thanks for your reply.

Regards

Arun.V

Quote:

Originally Posted by r_nairtvm

(Post 4484594)

Essentially what you are saying is the process

The following is from a good friend who is a restorer based in Dubai (KPS, you know who :))

"Likely these bearings like rest of the bearings of that period would be made of white metal, to which new white metal can be melted on to the (old) shell and when cold it can be machined to size required.

I am sure this engine is a low RPM engine and probably long stroke

Hope this clears your doubt in this regard

Best Regards & Drive Safe

Ram

|

Thanks Ram of giving a better explanation. My regards to the restorer in Dubai.

Absolutely right in that, this is a low RPM and long stroke engine!

Arun, thanks for your interest.

Finally the engine parts will shipped from UK this week by courier.

Time to speed up the body work and complete the painting

The roof needs little tapping. The painting team fortunately is uncompromising!

The rear view of the body

The work is being completed with much care

The naked B Pillar shows the quality of the car

Cheers

KPS

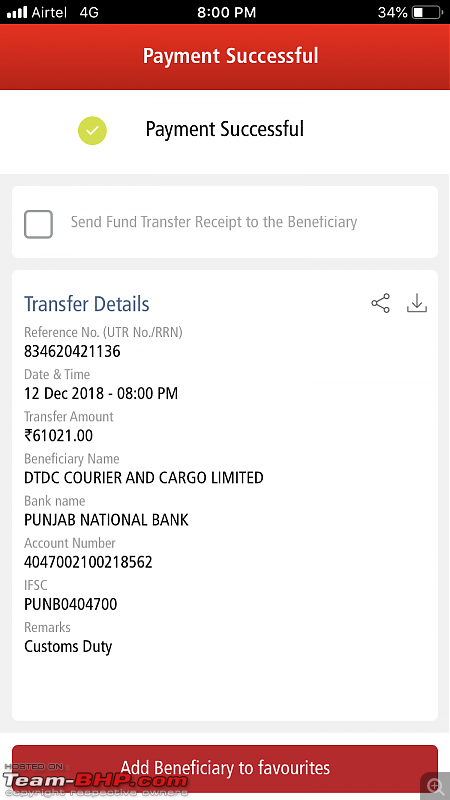

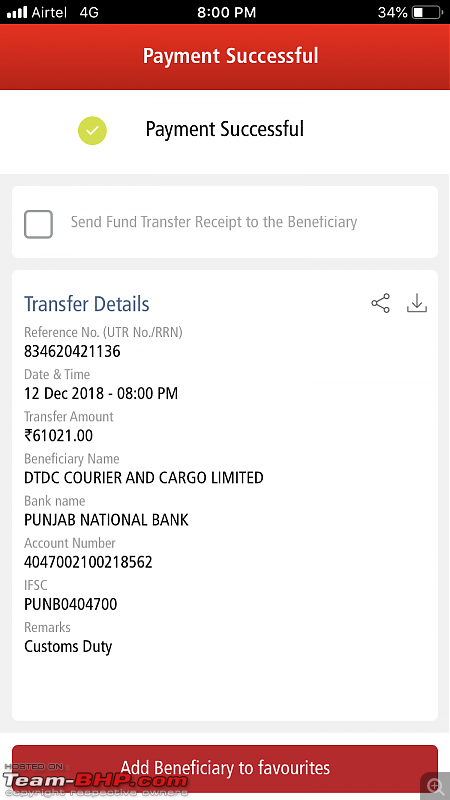

My last parcel from England arrived after significant delay. The supplier had delayed by 6 months and the courier guys took another 40 days to clear the same through customs!

I was tense as this parcel was most important considering it had key engine parts, namely the main bearings, piston rings and the harmonic balancer.!

Customs duty at 40+ percent. I was more relieved that the parcel had not been opened and all the parts arrived safely.

I went to the courier office and collected the parcel. All after these tense days, I was not going to wait for them to deliver.

Some other rare to find items also arrived. The jewel lights in my car were in very bad condition. Was able to get a replacement, used ones in good condition

The cigarette lighter has been missing for decades. The period photos too show this as missing on the dash. This is very difficult to get and I am so glad to have been able to get it. Completes the dash fully.

Thanks the David Beales, the DB18 specialist in UK for sourcing the jewel lights and cigarette lighter.

Cheers

KPS

Quote:

Originally Posted by KPS

(Post 4487430)

My regards to the restorer in Dubai.

KPS

|

KPS, you recall your visit to the Dubai Restorer's premises? He has now shifted his mundane (cotemporary) cars works to a new place and has revamped the old premises exclusively for classics. This is a sample of what it looks like now :)

Quote:

Originally Posted by KPS

(Post 4513167)

I was tense as this parcel was most important considering it had key engine parts, namely the main bearings, piston rings and the harmonic balancer.!

|

Glad that you got all of your key parts list inclap:

Look forward to the finished works

Best Regards & Drive Safe

Ram

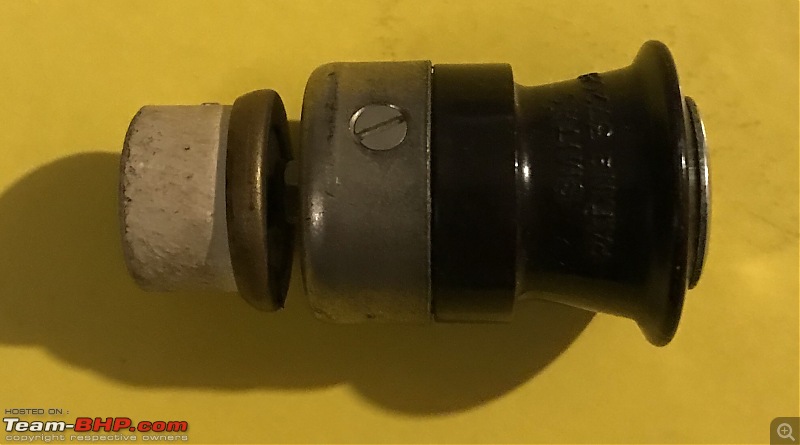

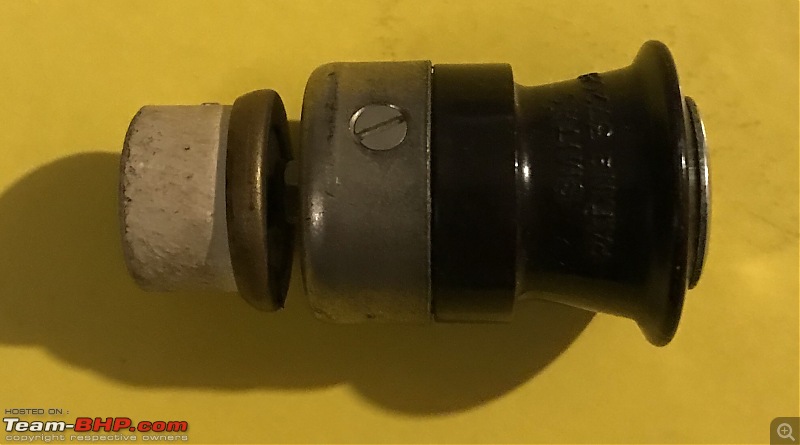

The quality of work is outstanding. Chris too was very pleased that our decision to send to the UK the Harmonic Balancer, Main Bearings and a Piston for accurate measurements to make rings, was worth it.

Quote:

The crankshaft harmonic balancer is a device connected to the front of an engine's crankshaft, usually built into the crankshaft pulley, which easily absorbs any harmonic vibrations that could harm the engine otherwise.

|

There rubber between the two metal pieces which absorbs the vibrations

The pulley in the from end

The main bearings

The oil rings in the piston

Piston rings

We can now peacefully start the engine rebuild work. Pistons are standard.

Cheers

KPS

The next few months are going to be exciting as we enter the final lap on this restoration.

Bulletboy is going to complete the paint job, Chris will simultaneously do the engine build up. Post painting, the car will come back to Chris's shop for the upholstery and final trim fitment, as Chris completes his work

The parts are now being moved to the paint booth. Bulletboy's team has done a super job in preparing the car for the paint.

Cheers

KPS

The bonnet has been prepared for the paint job

We apply Epoxy Primer on the bare metal, followed by Glasurit surfacer. 3M Body Filler at each stage, to ensure that the lines are good.

Thanks

KPS

Hi Mr. KPS

Excellent bodywork work and finish KPS.

Are you getting it done in Bangalore or somewhere else? If its in B'lore hope you don't mind if i can take a look at it when i am there in B'lore next week.

cheers

Dr. Kannan

Quote:

Originally Posted by Drkannant

(Post 4523028)

Are you getting it done in Bangalore or somewhere else? If its in B'lore hope you don't mind if i can take a look at it when i am there in B'lore next week.

cheers

Dr. Kannan

|

Yes this is in Bangalore. You are most welcome to see the car. The work is being done by Bulletboy at his workshop. Even I am getting excited as the work is coming towards completion of the paint job.

Thanks

KPS

| All times are GMT +5.5. The time now is 09:51. | |