| Re: MPR 4142, 1959 Fiat 103D Select Restoration.

Guys I am back after being blocked due to a malware attack on my PC. Thanks to GTO for understanding the problem.

Some updates my Fiat - After the mechanical restoration I have had few issues with the original distributor. So a replacement Lucas was sourced temporarily and with that car runs nice.

However The only issue - Non vacuum original carb with Vacuum distributor so I am not utilizing the full potential of the engine. But it drives great. So original MM distributor will have its paly taken out and and electronic point will be put in place.

And also it was decided to paint the car - Verde (Green), so paint shade of fiat green from Glasurit was chosen, however that turned out to be - the famous Bangalore Autorickshaw color.

So Gave a 1:18 Triumph Spitfire in BRG to paint the car.

Here is the car, getting washed after all the work.

The car in the parking. Note the eleven hundred logo which was resin casted at home.

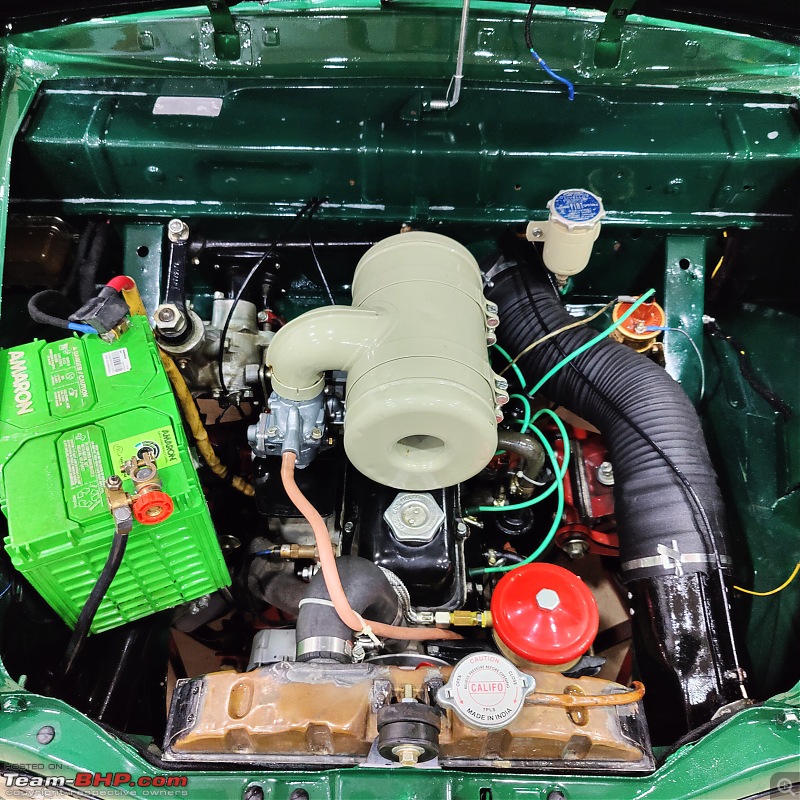

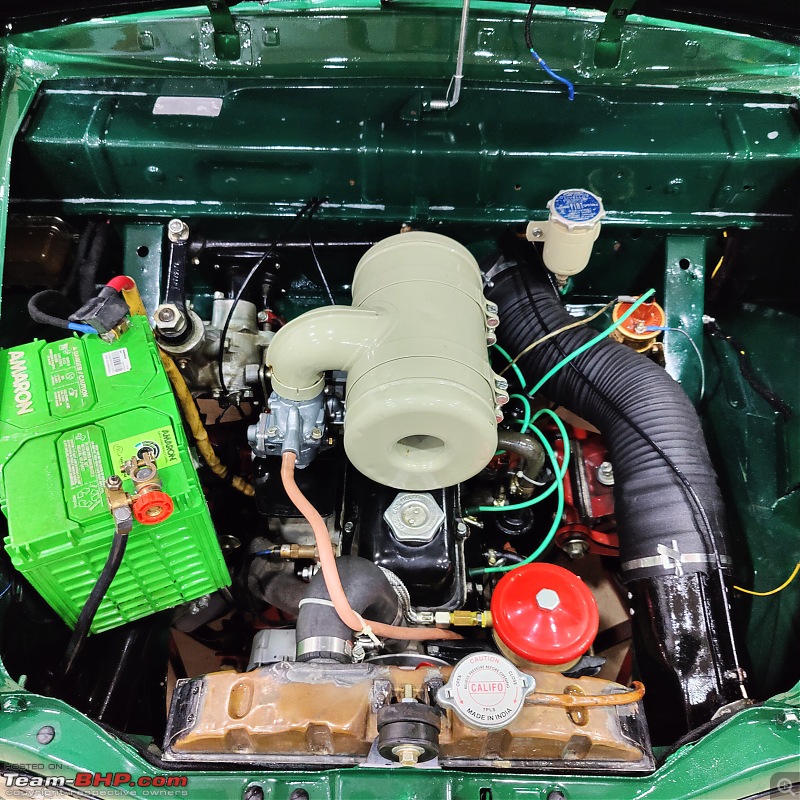

The engine bay is all cleaned and nice - The air hose is reproduced as original by bhpian Rony Vesuna @President - Many thanks for that. The Air duct was purchased from USA and thus comes with an electric fan.

Fiat experts have corrected me on the radiator top tank color and that has been done after this. Holding good so far.

The carburetor is all shiny, thanks to bhpain DKG @DKG for vapor honing and Chandana grinding to surface grind the faces.

CDC logo adorns the windshield - provided by bhpian Prithvi @mbz180

The ignition switch receives the badge, this is again resin cast at home from original.

Lastly it had been nearly impossible to get parts, the windshield washer bottle is one of that - thanks to bhpian Sarajit @Twincam for gifting me a broken one to measure accurately, with that I have a 3d print. so resin cast in clear will be done in near future.

There are more updates but that will come later. Thanks for watching. It's good to be back.

Last edited by manishalive : 10th June 2023 at 17:59.

Reason: Spelling correction.

|  (1)

Thanks

(1)

Thanks

(10)

Thanks

(10)

Thanks

(29)

Thanks

(29)

Thanks

(3)

Thanks

(3)

Thanks