Team-BHP

(

https://www.team-bhp.com/forum/)

-

4x4 Vehicles

(

https://www.team-bhp.com/forum/4x4-vehicles/)

- -

1990 M&M Cj340

(

https://www.team-bhp.com/forum/4x4-vehicles/63255-1990-m-m-cj340-27.html)

Job done...

3M anti-corrosive (Under body treatment) liquid is actually so solid, that no painter agreed to spray it using their std spray gun, they said it needs a special applicator.

So I went ahead with a 60Rs brush, did a DIY, then got this Bitu sheet for 90Rs per meter. The plastic will peel off ONLY when the sheet is cool not hot/warm!!! Once peeled off - it is just a stick on job.

Quote:

Originally Posted by svsantosh

(Post 2467929)

Job done...

3M anti-corrosive (Under body treatment) liquid is actually so solid, that no painter agreed to spray it using their std spray gun, they said it needs a special applicator.

So I went ahead with a 60Rs brush, did a DIY, then got this Bitu sheet for 90Rs per meter. The plastic will peel off ONLY when the sheet is cool not hot/warm!!! Once peeled off - it is just a stick on job. Attachment 592685 Attachment 592686 Attachment 592687

|

Wow! good job Santosh. I feel Bitu to be interesting, any specific standard/brand you need to ask for, I am not sure if it is available in Hyderabad, if any one please let me know the location, I guess this will solve the issue of rusting inside as the these monsoons are harsh on our Jeeps, water and moisture tends to stay below the carpets and starts eating the floor. I hope I find one this kind in Hyderabad.

Chanu, the brand name is in the pic. I think this bitu-tech-industries is a fairly common product. The place you need to go to is any hardware store that sells asbestos roofs (used in temporary hutments, factories etc). This product is called 'roof shield' and does exactly that. See prev page for more details of it. Let me know if you need me to send it over in a truck... (not worth it, costs cheap to buy but weighs a TON!!) 10 meters costed ~1000Rs but was nearly 15Kilos.

The only problem with using this sheet is that it is combustible and if you need to work on any metal part with a welding torch, it could be a problem!

Quote:

Originally Posted by jyobeb

(Post 2468643)

The only problem with using this sheet is that it is combustible and if you need to work on any metal part with a welding torch, it could be a problem!

|

Does this also means that the area near exhaust piping / silencer is prone to damage/melt or in worst case cause fire ?

I have heard people using this on vehicles & now seeing it in detail . I have never used it ( on vehicle ) though I was tempted many times as I have used similar material elsewhere ,but stayed away as I never got correct Info on this point.

Sudarshan

Yes it will melt. This are bitumen sheets that are used on roofing to stop leaks. If it will catches fire it will smolder for a long time.

You are Correct Jyobeb, My jeep already had some leftover bitumen sheet from previous owner/rebuild. So while tinkering was happening, the leftovers used to smoulder and melt under the intense heat of tinkers torch. Needed a dab of water to douse it...

Quote:

Originally Posted by jyobeb

(Post 2468643)

The only problem with using this sheet is that it is combustible and if you need to work on any metal part with a welding torch, it could be a problem!

|

Uh-Oh, there go my plans for installing this sheet in my Jeeps.

Quote:

Originally Posted by svsantosh

(Post 2469330)

You are Correct Jyobeb, My jeep already had some leftover bitumen sheet from previous owner/rebuild. So while tinkering was happening, the leftovers used to smoulder and melt under the intense heat of tinkers torch. Needed a dab of water to douse it...

|

Santosh then i suggest you reconsider using this material. I was actually thinking of using this in the engine compartment and firewall but this is a potential time bomb and i think ill pass. I will stick to the Wurth treatment.It is called the SKS Stoneguard and im told by the Wurth representative that, its the thing to use in the floor pan of cars. Very much like the Raptor bedliner, Fazalbhai has used in his CL340.

I hope Pavan is not using this in his engine compartment, given how prone to catching fire a VW beetle and micro bus engine is.

Gogi - engine bay - NO NO... Everywhere else, np. If you have seen the 'thar' used in road surface, this is just that. It is not a easily combustable material. Even under a welders torch it will only melt and deform and start to smoulder but not flame out as in paper, for example.

Even if have/wish to, I cannot take it out of the jeep now!! It is that sticky and has already bonded to the sheet metal like skin. I need a kerosene blow torch to burn/melt out the entire stuff out!! Two days in hot sun in the same position as pic ^ has made it a permanent mod!!

As for the wuerth treatment - do a DIY. Get a 3M antirust paint can (not exactly a paint, it is called rubber paint in local shops), get a brush and some petrol/thinner, thin the product and just spend 30mins to cover the entire floor.

Ref :

POST in samus thread.

Quote:

Originally Posted by DHABHAR.BEHRAM

(Post 1991485)

.....As far as solenoid switch is concerned, after you remove the 27 mm spanner switch body (for which you would ideally use a 27 mm size deep box spanner), there is a plunger inside. If you remove the plunger and keep it and put the 27 mm cover only, the solenoid does not perform its intended function of stopping the fuel flow so you can merrily drive the vehicle even with a dead battery or in the worst case even without a battery. I recall that in the rotary FIP, there used to be a mechanical stop lever, which could be operated by a cable similar to the MDI engine. Just check if the lever is there. If yes, please attach a cable and use it to stop the engine and just knock the solenoid plunger off.

|

Dear Dhabhar ji, Stage 1 Completed : I have attached a (choke) cable from a Trax Judo to the 'mechanical stop lever' in the FIP. Now the jeep stops with the pull of this lever.

Stage 2 of removing the solenoid will be done tomm, after a day of testing this cable mod.

^^^

Anyone can now push start your vehicle and drive away with it!

Regards

Sutripta

Quote:

Originally Posted by Sutripta

(Post 2472799)

^^^

Anyone can now push start your vehicle and drive away with it!

Regards

Sutripta

|

Talking about push start, in the last two weeks, three jeeps have been stolen from Coonoor. High time we think of some real fool proof mechanism to prevent theft.

Quote:

Originally Posted by V-16

(Post 2469540)

I will stick to the Wurth treatment.It is called the SKS Stoneguard and im told by the Wurth representative that, its the thing to use in the floor pan of cars. Very much like the Raptor bedliner, Fazalbhai has used in his CL340.

|

Gogi Bhai,

Raptor

(2 coats) has an advantage, it comes out thicker than Wurth, which translates into better dynamics, lesser road sound, less vibration. Use Wurth for under body. I did too.

I have not done any matting yet, or pasting heatlon on the vertical fire wall which is due after monsoons, this will bring down the present heat and noise levels radically. Another advantage with Raptor is its anti corrosive properties, during AKC and EXAMM, and until I got back to Hyderabad, there was water and dampness on the cabin floor all through due to rains and water fording, still not a spot of rust.

Regards,

Quote:

Originally Posted by Sutripta

(Post 2472799)

Anyone can now push start your vehicle and drive away with it

|

Aara Dada... As if having a key was fool proof :D ... During Dr.Madhus (black 540) jeep restoration I lost the key in the pitch dark area of the welder shop. Took 1 screw driver and removed the switch assy and made the wires direct and drove the jeep for 2 days before I could bring the spare key from docs home.

--------------------------

Stage 2 complete:

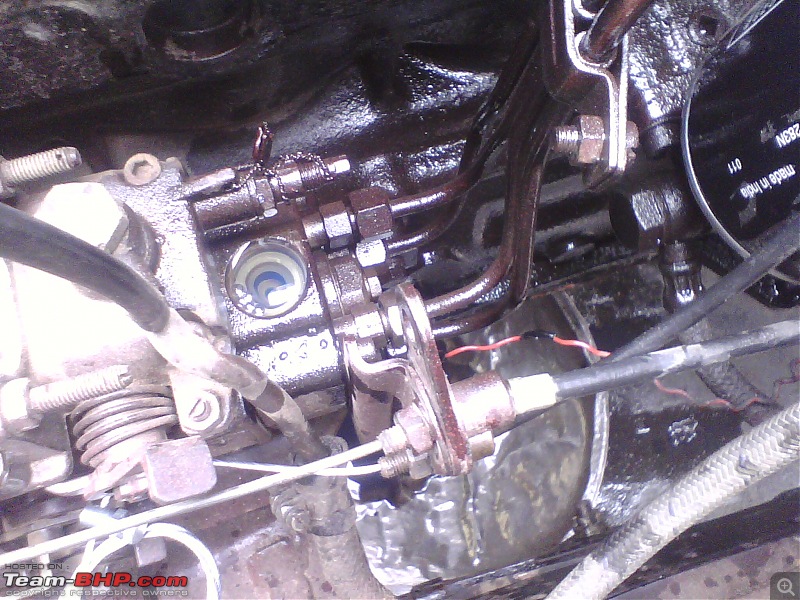

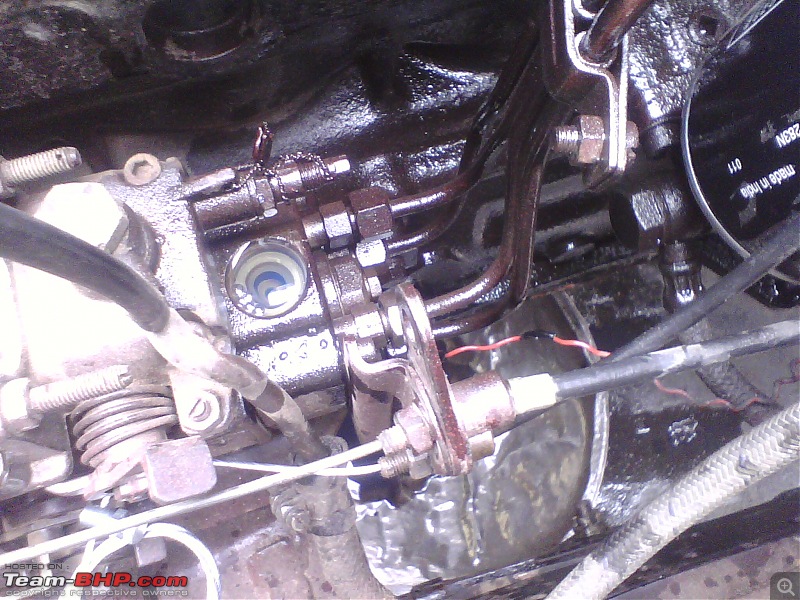

Samu, you would be surprised the this operation took only 10 mins max. See the position of the spanner used by my mech.

This side with the tiny little thread is what is visible from outside and the wire connects here.

Side view

Bottom where the actual moving part sits

Actual switch with a moving spring in it

FIP without the solenoid in it - Ps, there was tiny amount of dust visible in here, mech quickly pumped the filter and diesel gushed out taking out the dust along with it.

The weakest part of the whole topic here - Mech explained (roughly) that if this spring fails/expands then the flow of diesel will restrict and lead to a choked engine. Dhabhar sir - please explain in your words...

Samu - this is the exact position in which the solenoid came out, did not need a box spanner, nor did any other filter/pipe came out of the way. Only the engine breather pipe was removed...

Now, for a video how to start/stop my jeep.

Jeep with choke cable - YouTube ...fin...

Quote:

Originally Posted by svsantosh

(Post 2473302)

Aara Dada... As if having a key was fool proof :D ... During Dr.Madhus (black 540) jeep restoration I lost the key in the pitch dark area of the welder shop. Took 1 screw driver and removed the switch assy and made the wires direct and drove the jeep for 2 days before I could bring the spare key from docs home.

|

Hi,

There is another scenario which you should consider. If you park your vehicle on an incline, step out for a recce, and the vehicle rolls, it will start up and run away from you! (Of course there are ways round it).

Thiefproofing a Jeep is difficult.

Regards

Sutripta

| All times are GMT +5.5. The time now is 20:11. | |