| | #1186 |

| BHPian | |

| |  (4)

Thanks (4)

Thanks

|

| |

| | #1187 |

| BHPian | |

| |

| | #1188 |

| Senior - BHPian | |

| |

| | #1189 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #1190 |

| Senior - BHPian Join Date: Dec 2006 Location: Mysore / B'lore

Posts: 1,668

Thanked: 4,122 Times

| |

| |  (9)

Thanks (9)

Thanks

|

| | #1191 |

| BHPian Join Date: Sep 2009 Location: Trivandrum

Posts: 932

Thanked: 1,217 Times

| |

| |  (5)

Thanks (5)

Thanks

|

| | #1192 |

| Senior - BHPian Join Date: Dec 2006 Location: Mysore / B'lore

Posts: 1,668

Thanked: 4,122 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #1193 |

| BHPian Join Date: Sep 2013 Location: Bangalore

Posts: 602

Thanked: 582 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #1194 |

| BHPian Join Date: Sep 2009 Location: Trivandrum

Posts: 932

Thanked: 1,217 Times

| |

| |  (7)

Thanks (7)

Thanks

|

| | #1195 |

| Senior - BHPian Join Date: Dec 2006 Location: Mysore / B'lore

Posts: 1,668

Thanked: 4,122 Times

| |

| |  (2)

Thanks (2)

Thanks

|

| | #1196 |

| BHPian | |

| |

| |

| | #1197 |

| Distinguished - BHPian  | |

| |  (1)

Thanks (1)

Thanks

|

| | #1198 |

| BHPian Join Date: Apr 2015 Location: Kolkata

Posts: 109

Thanked: 66 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #1199 |

| Distinguished - BHPian  Join Date: Jun 2007 Location: Chennai

Posts: 11,007

Thanked: 26,449 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| | #1200 |

| BHPian | |

| |

|

Most Viewed

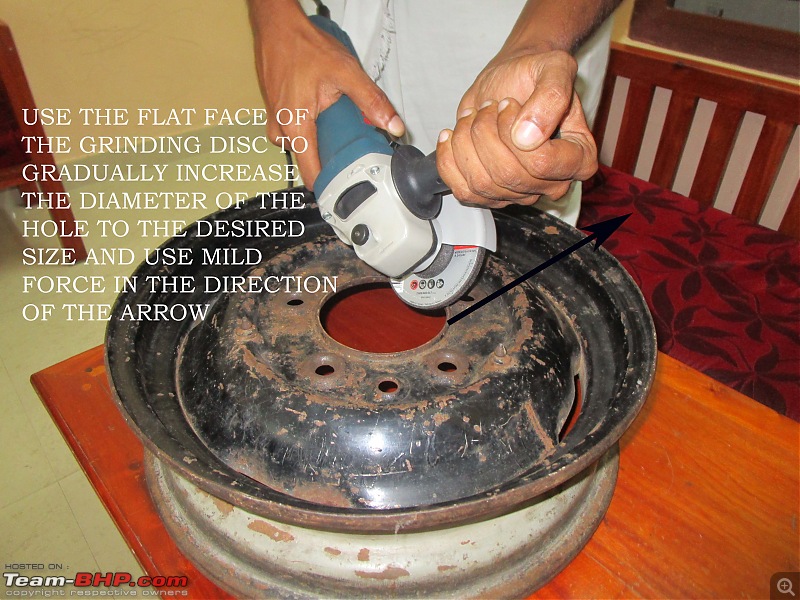

although my arms got blasted quite nicely. Any tips on how to avoid the burns?I always held it such that the sparks would fly away from me but they still ricocheted and kept hitting my arm.

although my arms got blasted quite nicely. Any tips on how to avoid the burns?I always held it such that the sparks would fly away from me but they still ricocheted and kept hitting my arm.