Picking up where Crazy left off-

I Picked up the car as CD was moving abroad. It was a spontaneous decision to buy it!

On Dec 26, 2010, i sent CD a sms at night saying ill be hitting blore to check out the car the next morning. He met me at the bus stop with this gleaming black car and we went for a spin! I was amazed at the crisp acceleration. At that point of time i was using a SX4 vvt and a Mivec lancer in its NA form bac home. I was clear in my mind that if the car performed better than the sx4 and the 0-60 felt similar to the mivec, i would pick it up for the asking price.

As luck would have it, the car impressed me and i had to buy it(bye bye to all my savings + hello to a personal loan). By 9am i was the proud owner of the car!

After a sumptuous breakfast prepared by CD's wife, idrove straight to Belgaum for a function and all i can say is i loved every minute of the drive! The car was so composed and had a good torque curve. I reached Belgaum in record time with a big smile on my face! Mileage returned was 12.8kpl with constant redlining.

Like every blore car, this one had its share of dents and dings. Took it in for repairs and ended up changing all the wheel bearings as well. CD, a true gentleman that he is immediately reimbursed the money i spent on the repair as promised earlier.

Over the last 17 months, the journey has been filled with a lotta ups and downs. I had 2 GB failures, one of which left me stranded in the middle of nowhere at night. The Mandovi mech said the car made a lot of power and thats the reason the bolts holding a flange in place sheared off and got stuck between the 5th gear cogs. I was like.. Lotsa power..my A$$. It was just poor workmanship by the guy who worked on the GB last. The Bolts were fastened too much. I took a day off from work and made sure everything was done by the book. I was happy to see the mech using a torque wrench- No kidding!!

I was given an option of picking up a Cultus GB but finances were a bit of a concern so just rebuilt the extisting one.

P.S Ive never done a hard launch. Just normal driving but with some hard acceleration and redlining in higher gears.

Apart from the GB issue, we had a rat infestation and the fat buggers pulled out some wires from the Wideband. We had to rely on the WWW and some some guesses from Karthik @ race dynamics(over the phone) to get the wiring right. Once fixed, i havent faced a problem with it.

Small yet expensive(!!) stuff like weather strips, some rubber stuff and the batt were also replaced over this period. There was an electrical leak(fixed) and ofcourse a dead tacho(electrical prob again). There are some more things that ill put them up as and when i recall.

If you'll want to know if my happy with this purchase even after the things ive been through, the answer is a definite YES! Shes a dream to drive, quite reliable, a Maruti(!!), Full service history, beautifully maintained interior and exterior and last but not least, a great enthusiastic and trustworthy (previous) owner.

The clock currently relfects 58.2k and mileage in city cycle is around 7 without ac. The reason for the mileage is that the car is used quite rarely as i prefer the bike, i warm up the car for a minute every time i take it out, the AD07's are sapping power as they have worn quite a bit and i have a very heavy right foot!

Ill leave you'll with some pics of the car.

The Gleaming ol' girl

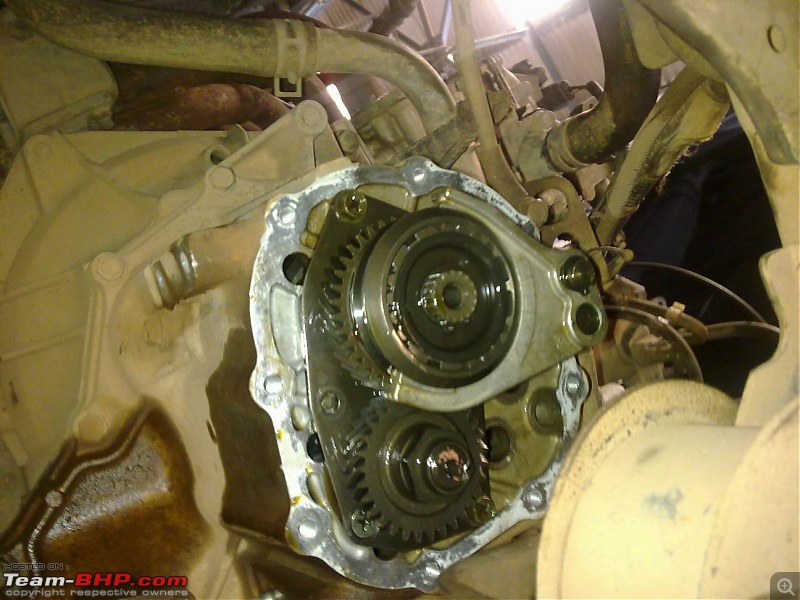

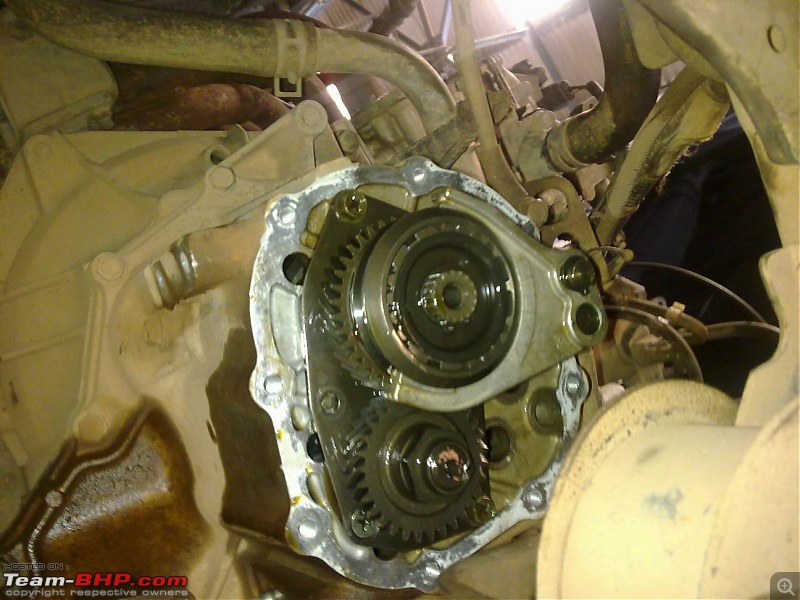

Pic of the GB the first time it broke down

The second time around i was wiser! I made them dismantle the entire GB, check every part for wear right in front of me and replace the parts that were out of spec.

The sheared off bolts that caused all the trouble on both the occasions.

The damaged 5th gr cogs (costed around 3k each)

Some weekend TLC. Swapping the wheels and spraying antirust into the door cavities etc.

Cheers!

(3)

Thanks

(3)

Thanks

(1)

Thanks

(1)

Thanks