DIY Fuel System Clean: After the fuel pump failed in 2017 due to sediments, I decided to have a look inside the tank to gauge the cleaning frequency. I was surprised that even after 3 years, there was considerable amount of sediment inside.

Didn't want to take GG to MASS as they will hardly dedicate this much time and effort to clean things. I wanted to do it my way with inputs from friends, mechanic and ex-SA Dhiraj.

Since I was alone doing it, couldn't take as many pics as I'd have wished. This is all I could manage:

1. Relieve the fuel pressure. To do that, I took out the fuel pump relay and let the engine run till it died. Then opened the tank cap, to release the built up pressure. This is important in MPFI cars and don't miss it. Carb owners may skip as there is no pressure in your lines.

2. Jack up the car from behind to access the fuel tank. First disconnect all hoses. There will be a thick inlet hose, a thin vapour line, One high pressure line from pump to filter, and a hose from filter to metal pipes.

3. Put a jack below the tank so that it gently touches it. Remove the 4 bolts holding the tank to the body. Slightly lower the tank and then disconnect fuel pump coupler and fuel gauge pin.

4. Lower the tank and then carefully pull it out.

Noticed this wet part which indicates a leak.

The gasket of fuel level sender unit was gone again. Unfortunately it's gasket doesn't come separately. But since I had a new sender unit, I used it's gasket.

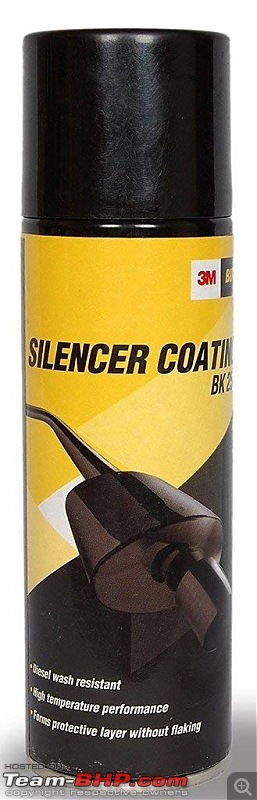

Also took this opportunity to remove the catcon and the silencer for another DIY:

The dirty Fuel Pump:

Drained around 3L of fuel and washed the internals once. Then allowed it to soak with APC overnight.

Cleaned the pump externally to reveal that it was originally a Japanese made unit:

New Sender Unit: It's gasket was used since the old unit was working flawlessly.

Cleaned and polished the hoses to reveal its actual condition. They were all in excellent shape.

Since the longer High pressure hoses are rare plus expensive( close to 3k a piece), I was advised by Dhiraj to cover it with a protector, since they are often targetted by rodents. Used MGP's protector.

20 Year old hose, still in excellent shape:

Ready to go in:

After tank had dried, it went for a fresh coat of paint. Didn't bother much about finish, protection had to be good:

Thanks to the summers, it was ready to touch and work with in an hour. Also installed new filter.

Opted to color code the HP and LP hoses

:

Cleaned the fuel pump coupler and applied electrical grease:

Replaced some frayed hoses:

Keeping a good stock at home helps, no running around for spares:

Needed some lock washer and bolts, found in my stock again!:

Using Jack again to mount the tank. The masking tape was used to protect the tank along edges during installation:

Also thought why stop at this. While the soaking was going on, decided to pull out the injectors and cleaned them myself using aerosol cleaner and the contraption I have made. Took a hose, put injector at one end and blocked the other end with a bolt. Made a tiny hole in between for cleaner nozzle to pass. Also made two wires to go into the injector terminals. Failed a couple of times, but after some mods(like putting clamps), it worked great. First tried to give voltage as pulses, as that's how the injector gets it. Continuous voltage should be avoided unless the injector is clogged(one in my case was) as the solenoid tends to get hot.

The contraption:

Sealed the tiny hole with glue gun and taped it later.

Working:

Hope you all liked it.

Regards,

Shashi

(18)

Thanks

(18)

Thanks

(35)

Thanks

(35)

Thanks

(4)

Thanks

(4)

Thanks

(5)

Thanks

(5)

Thanks

(8)

Thanks

(8)

Thanks

(27)

Thanks

(27)

Thanks

(3)

Thanks

(3)

Thanks

(2)

Thanks

(2)

Thanks

(5)

Thanks

(5)

Thanks

(4)

Thanks

(4)

Thanks

(1)

Thanks

(1)

Thanks

(4)

Thanks

(4)

Thanks

(1)

Thanks

(1)

Thanks

(2)

Thanks

(2)

Thanks

(1)

Thanks

(1)

Thanks

:

:

Avoid 80W90.

Avoid 80W90.

The gasket of fuel level sender unit was gone again. Unfortunately it's gasket doesn't come separately. But since I had a new sender unit, I used it's gasket.

The gasket of fuel level sender unit was gone again. Unfortunately it's gasket doesn't come separately. But since I had a new sender unit, I used it's gasket.

:

: