| | #106 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| |

| |

| |

| | #107 |

| BHPian | |

| |

| | #108 |

| BHPian | |

| |

| | #109 |

| BHPian | |

| |

| | #110 |

| BHPian | |

| |

| | #111 |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,766

Thanked: 9,054 Times

| |

| |

| | #112 |

| BHPian Join Date: Dec 2007 Location: USA / Bangalore

Posts: 209

Thanked: 23 Times

| |

| |

| | #113 |

| BHPian | |

| |

| | #114 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #115 |

| BHPian | |

| |

| | #116 |

| BHPian Join Date: Jun 2007 Location: Hyderabad

Posts: 54

Thanked: 2 Times

| |

| |

| |

| | #117 |

| BHPian | |

| |

| | #118 |

| BHPian | |

| |

| | #119 |

| BHPian Join Date: Nov 2008 Location: india

Posts: 209

Thanked: 5 Times

| |

| |

| | #120 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

|

Most Viewed

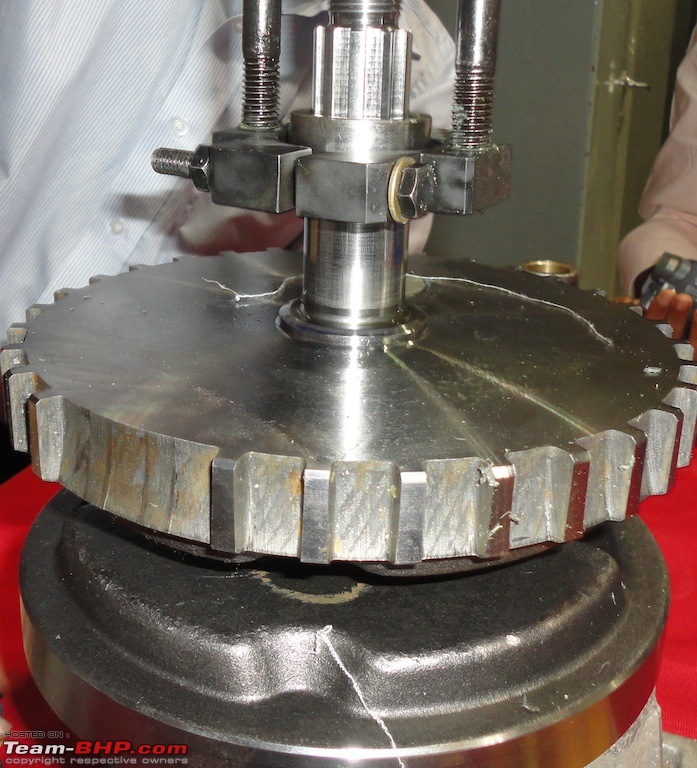

. This was unacceptable and meant that we had to design and develop the tool in house. I will not go in to the details of that process. At the end of about a week the tool was designed, machined, checked one final time and sent for heat treatment.

. This was unacceptable and meant that we had to design and develop the tool in house. I will not go in to the details of that process. At the end of about a week the tool was designed, machined, checked one final time and sent for heat treatment.