| | #121 |

| BHPian Join Date: Nov 2008 Location: india

Posts: 209

Thanked: 5 Times

| |

| |  (1)

Thanks (1)

Thanks

|

| |

| | #122 |

| BHPian | |

| |

| | #123 |

| BHPian Join Date: Nov 2007 Location: Mumbai

Posts: 384

Thanked: 611 Times

| |

| |

| | #124 |

| Senior - BHPian Join Date: Dec 2007 Location: CNN/BLR

Posts: 4,243

Thanked: 10,091 Times

| |

| |

| | #125 |

| BHPian | |

| |

| | #126 |

| BHPian | |

| |

| | #127 |

| BHPian | |

| |

| | #128 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #129 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #130 |

| BHPian | |

| |  (1)

Thanks (1)

Thanks

|

| | #131 |

| Senior - BHPian Join Date: Jan 2010 Location: TSTN

Posts: 6,236

Thanked: 9,643 Times

| |

| |

| |

| | #132 |

| BHPian | |

| |

| | #133 |

| Senior - BHPian Join Date: Jan 2010 Location: TSTN

Posts: 6,236

Thanked: 9,643 Times

| |

| |

| | #134 |

| Senior - BHPian Join Date: Jul 2009 Location: Pune

Posts: 1,074

Thanked: 660 Times

| |

| |

| | #135 |

| Senior - BHPian | |

| |

|

Most Viewed

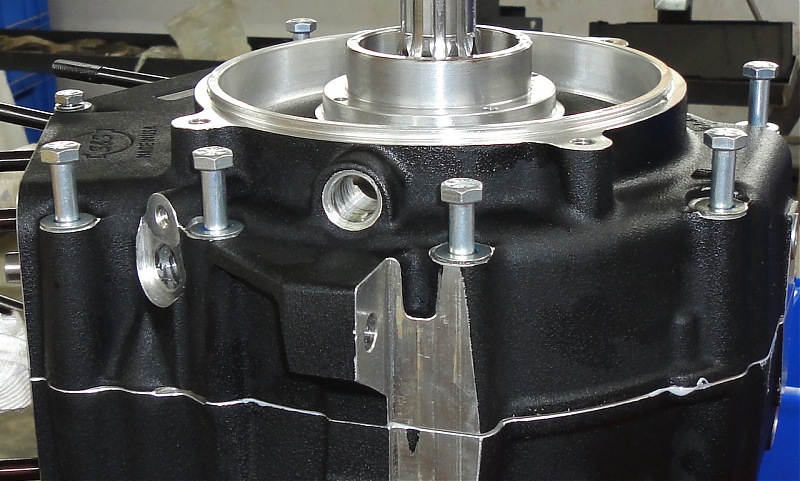

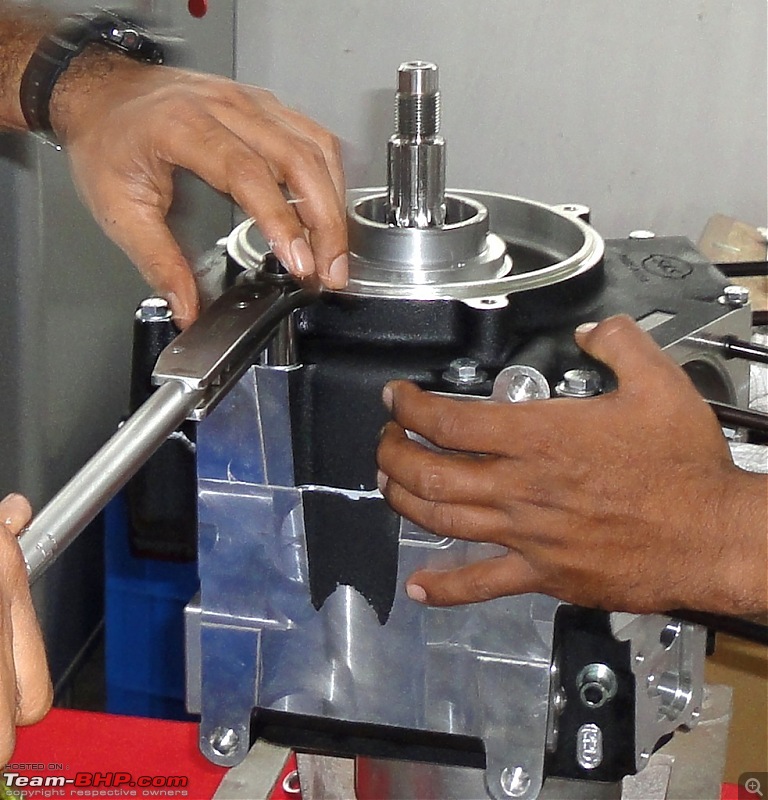

designed a TOOL for installation, checked, re-checked, tested and after putting in all that effort Mr. Timken just slipped over the crankshaft without applying any force or use of tool. On close inspection we realized that the bearing was not sitting on the crank shoulder, we finally got the opportunity to use our tool to guide it to the designated spot.

designed a TOOL for installation, checked, re-checked, tested and after putting in all that effort Mr. Timken just slipped over the crankshaft without applying any force or use of tool. On close inspection we realized that the bearing was not sitting on the crank shoulder, we finally got the opportunity to use our tool to guide it to the designated spot.