| |||||||

| Search Forums |

| Advanced Search |

| Go to Page... |

|

| Search this Thread |  571,717 views |

| | #1 |

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| DSG, demystified! All you need to know about VW's Direct-Shift Gearbox DSG. The very mention of the word can bring about a range of emotions – right from  to to  In this thread, intend to capture and publish the entire range of emotions with as much as underlying data as possible. I have tried to assimilate information with an intention for all of us BHPians (and of course, the wide world too) to refer to a ONE VIEW or place for anything and everything related to the subject of DSG. If there is anything that you feel needs to be added to enhance the contents of this subject, please feel free to do so. Ofcourse, as you will see, I have tried to arrange and present information in a certain chronological way (by means of an index) and would appreciate if you can suggest contributions or recommendations accordingly. By no means, do I claim this compendium to be exhaustive – infact, it is expected to be a “living” discussion - that evolves, lives and grows over time. Presenting the index:- The DEFINITION - well, just to start off the discussionHope you enjoy "revving" the thread! Last edited by Aditya : 4th October 2021 at 21:42. Reason: As requested |

| |  (75)

Thanks (75)

Thanks

|

| The following 75 BHPians Thank JoshMachine for this useful post: | --gKrish--, 773.raviteja, Aceman82, akash_v12, anshumandun, arjab, audioholic, Aurum, bhpfaninblr, biller777, BMvW.Rajat, CarLoverJosh, cs_rajesh, Deep Blue, DrANTO, Driver 33, epicenter.rulez, Evyas, francis_vaz, Gannu_1, ganny, GForceEnjoyer, Grand Drive, GTO, hemanth.anand, hmansari, IndigoXLGrandDi, jagzrk, jailbird_fynix, Javelin, Jeevith, Joxster, KA19Rao, Keynote, Leoshashi, MotorDev, Mukund, n.devdath, N33raj, nachiketparate, neoonwheels, nsd9, Omkar, R2D2, Rigid Rotor, roadie_swift, roadrunner_nv, Roy.S, Rudra Sen, sandx, Sankar, satya180, sechebe, shancz, sharktale, Shrix458, SILVER-ARROW, Simat, SLK, SnS_12, sriharsha_m87, stringbh, Surprise, Surya1, Sutripta, Thad E Ginathom, The Rationalist, The_Outsider!, TOR, Tormoz, TSIboy, Turbanator, Varun_HexaGuy, Vik0728, vinitbarve |

| |

| | #2 |

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox The DEFINITION Parentage German. Name: Direkt-Schalt-Getriebe / Dual Shift Gearbox, commonly abbreviated as DSG. Perhaps this widely viewed YouTube video on its functioning is a good way to start off the proceedings: Albeit, VW also has a video on 'Knowing your DSG' but it doesn’t “shift” much, if you get what I mean:- Needless to say, there are tons of videos out there which explain the concept vividly. The most elementary definition of the DSG is perhaps that it is an electronically controlled dual-clutch, multiple-shaft manual gearbox i.e. it comprises two separate manual gearboxes (and clutches) contained within one housing and working as one unit. Back to index Last edited by JoshMachine : 11th December 2018 at 13:43. |

| |  (33)

Thanks (33)

Thanks

|

| The following 33 BHPians Thank JoshMachine for this useful post: | --gKrish--, akash_v12, amit1agrawal, ashis89, audioholic, Driver 33, epicenter.rulez, Gannu_1, GForceEnjoyer, GTO, hemanth.anand, hmansari, jailbird_fynix, Joxster, MotorDev, N33raj, PearlJam, R2D2, roby_dk, Roy.S, Rudra Sen, sagwal, Sankar, Santoshbhat, shancz, Shrix458, Simat, SnS_12, Sutripta, tchsvy, Thad E Ginathom, The_Outsider!, Varun_HexaGuy |

| | #3 | ||||

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

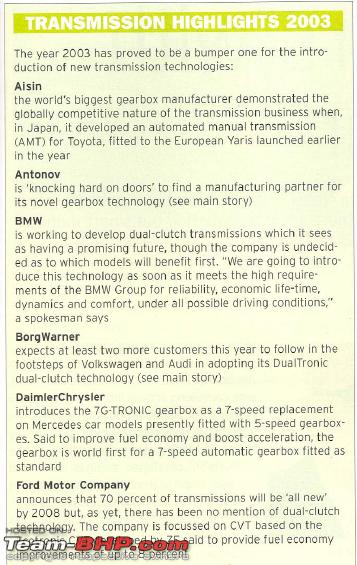

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox The LAUNCH and INITIAL SUCCESS

Back to index Last edited by JoshMachine : 11th December 2018 at 13:46. | ||||

| |  (39)

Thanks (39)

Thanks

|

| The following 39 BHPians Thank JoshMachine for this useful post: | Added_flavor, amit1agrawal, ashking101, audioholic, CarLoverJosh, Driver 33, Evyas, Gannu_1, GForceEnjoyer, GTO, hemanth.anand, hmansari, InControl, jailbird_fynix, Jeevith, Joxster, Leoshashi, MotorDev, N33raj, PM - B, R2D2, Rajeevraj, roby_dk, Rudra Sen, sagwal, Sankar, Santoshbhat, shancz, shipnil, Shrix458, SILVER-ARROW, SilverSmoke, Simat, SnS_12, suhaas307, Sutripta, tchsvy, Varun_HexaGuy, WasavaTyres |

| | #4 |

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

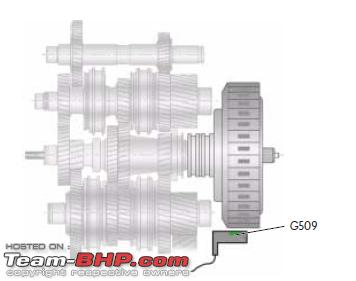

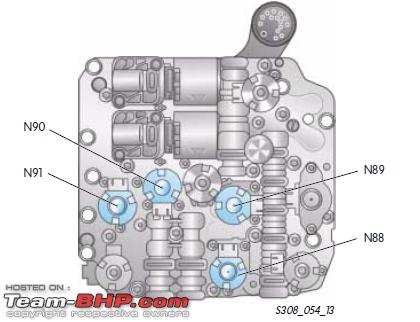

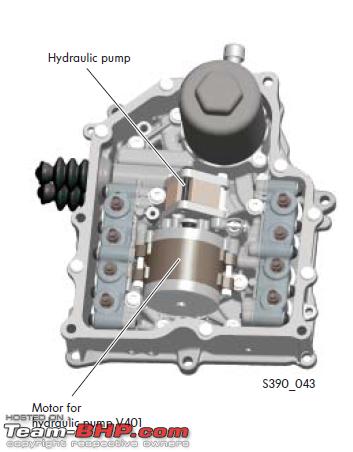

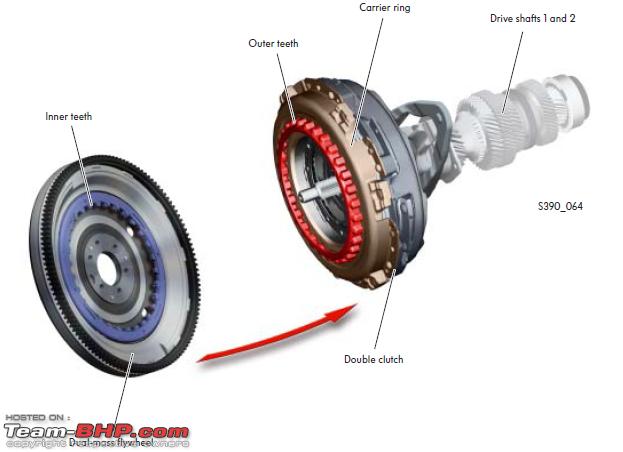

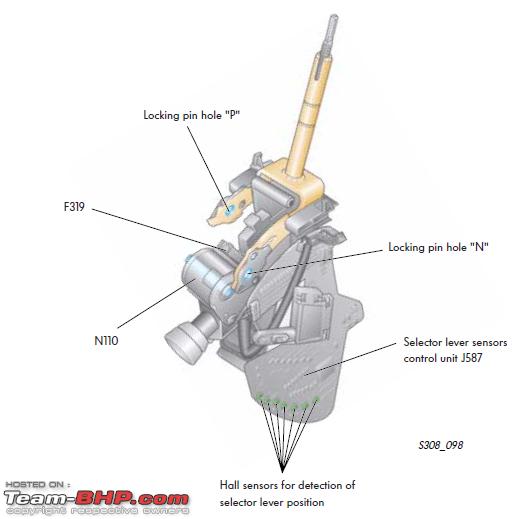

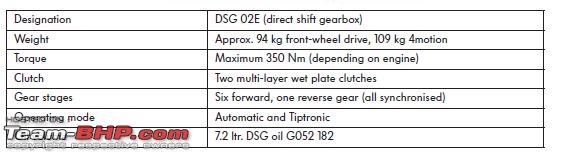

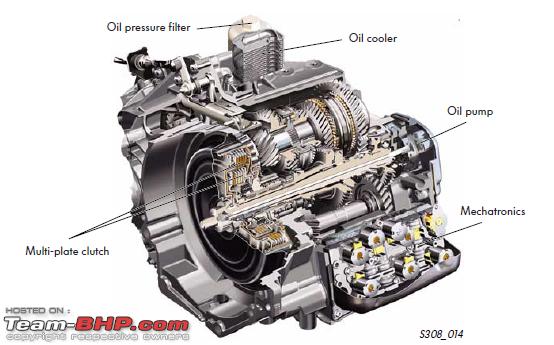

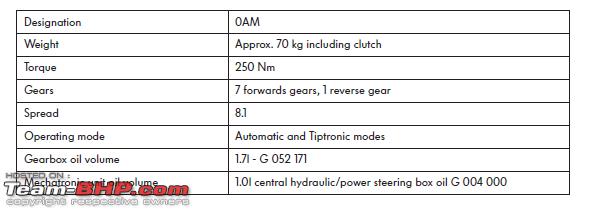

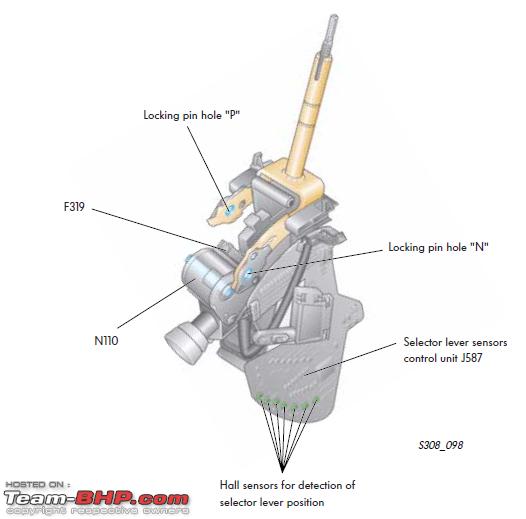

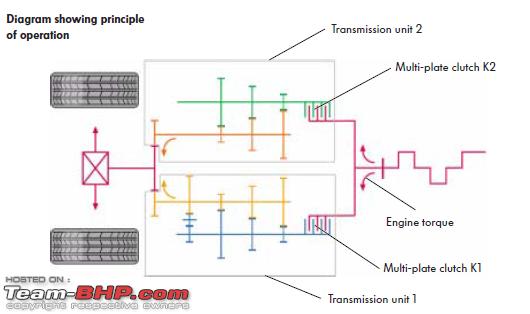

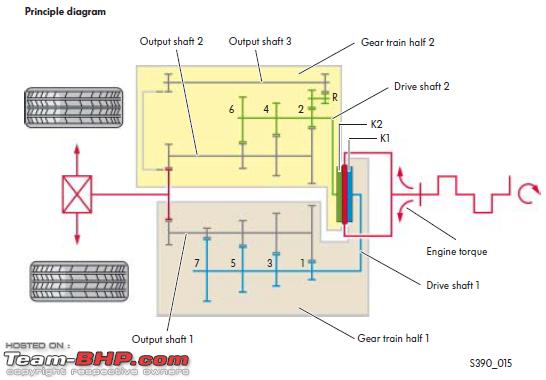

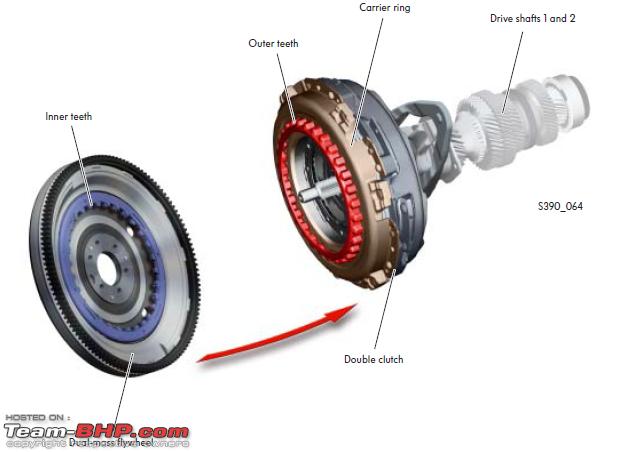

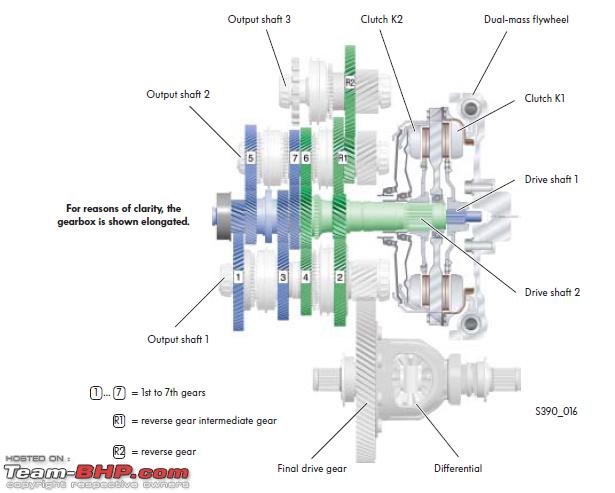

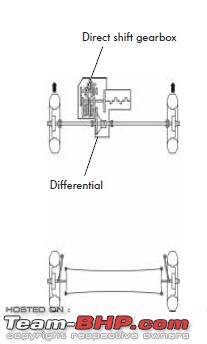

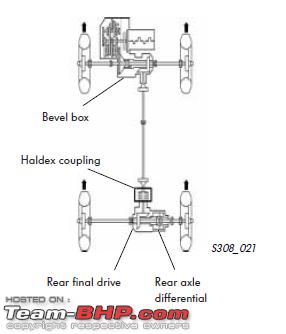

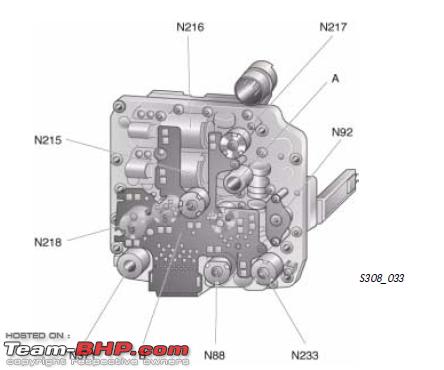

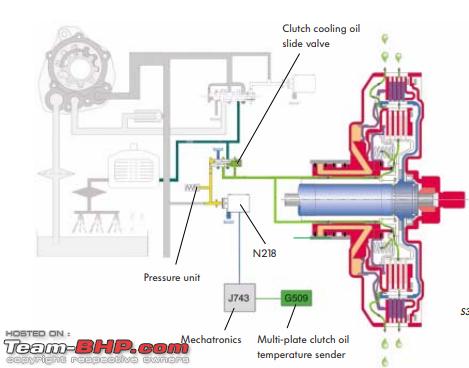

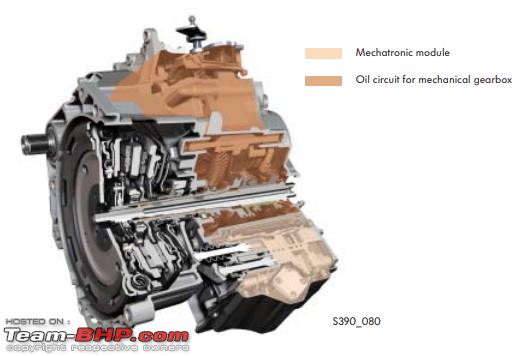

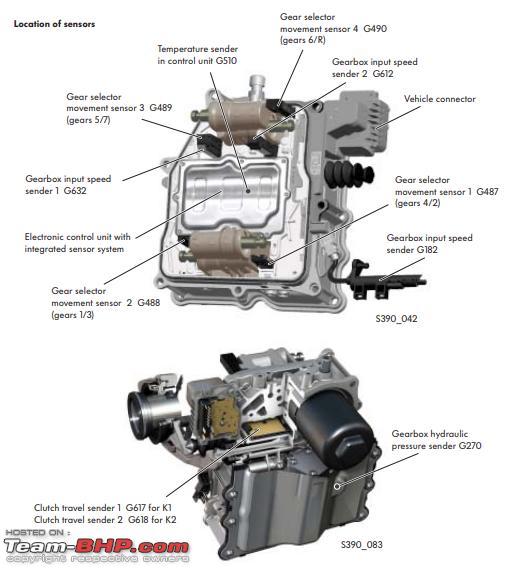

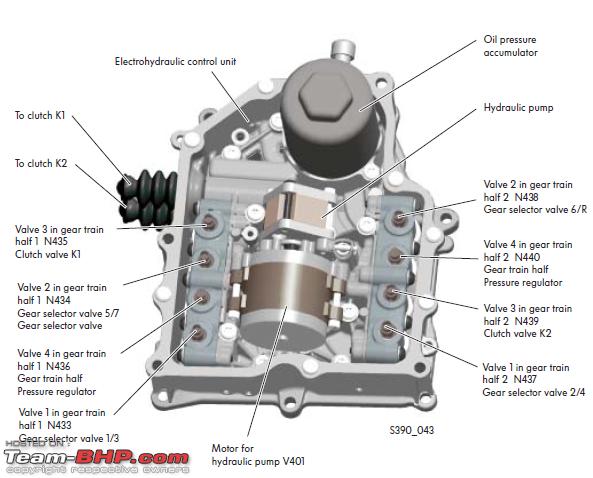

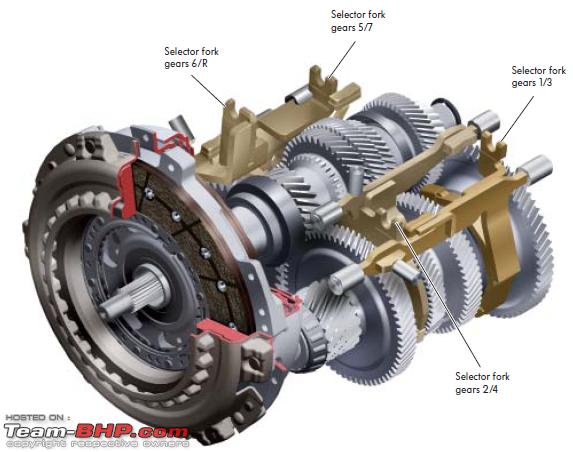

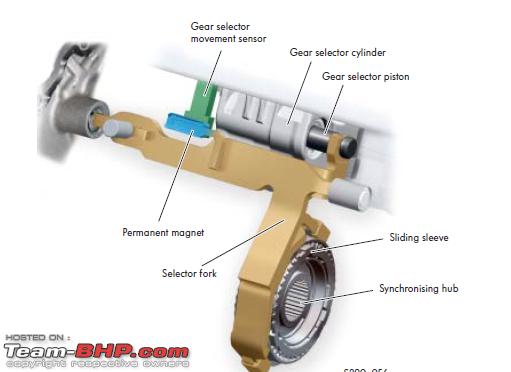

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox The WORKS For the uninitiated, this section really gives you a ringside view of the design and what/how VW came up with such mind-blowing technological innovations. For reasons attributed to sales volumes, intend to focus on the two most popular gearboxes – the DQ250 and the DQ200. Introductory data for the DQ250:  With the section-wise image of the gearbox unit with the multi-plate clutch:  And similar info for the DQ200:  Along with the section-wise image with the double clutch:  The source of the extra weight for the DQ250 can be clearly attributed to the ~5 times the amount of gearbox oil, along with the number of clutch plates. This also clarifies the wrongly-held view that the DQ200 is a totally "dry" unit. Also explains the rationale why VW wanted to have the lighter, 7-speed gearbox - mainly to cater to smaller engine/relatively higher volume cars. Selector level design is common to both gearboxes:  In the above selector design, the "hall sensors" play a very critical role since they act as the primary feed in case of any failures for the gearbox. More on that later. Principle diagram for the DQ250:  1st, 3rd, 5th and reverse gear are selected via multi-plate clutch K1. 2nd, 4th and 6th gear are selected via multiplate clutch K2. Both the multiplate clutches are submerged in oil. And for the DQ200:  Gears 1,3,5 and 7 are shifted via clutch K1 whereas gears 2, 4, 6 and reverse are shifted via K2. Note how the DQ200 clutches are arranged concentrically, to aid in compact gearbox design. When it comes to the very important activity of torque transmission inside the gearbox, this diagram probably explains it quite nicely:-  The torque is transferred from the dual mass flywheel, which is secured to the crankshaft, to the clutch plates. The above diagram is for the DQ200 but the mechanism remains the same in the DQ250 also. Some cases of shuddering in the DSG gearboxes have been also attributed to the improper torque transfer by the dual mass flywheel. And the below diagram explains the end to end view of the entire torque transfer, per se:-  This diagram is again depicted for the DQ200 dual clutch gearbox. After "receiving" the torque from the mass flywheel, the clutch K1 transfers the torque further to drive shaft 1 (marked in blue color). From drive shaft 1, the torque for gears 1 and 3 is transferred to output shaft 1 and that for gears 5 and 7 to output shaft 2. And the other clutch K2 transfers the torque to drive shaft 2 (marked in green color). It transfers the torque for gears 2 and 4 to output shaft 1 and the torque for 6th and reverse gear to output shaft 2. Via intermediate reverse gear R1, the torque is then passed to reverse gear R2 on output shaft 3. And now for the torque transmission outside the gearbox, the below diagram mentions that on front-wheel drive vehicles, the drive shafts transmit the torque to the front wheels.  And for 4-wheel drive vehicles, in addition to the front wheels, the torque is transmitted to the rear wheels via a bevel box, wherein a propshaft transmits the torque to a Haldex coupling. Integrated in this rear final drive is a differential for the rear axle.  Next, is an important part of the gearbox, referring to what is termed as the brain of the DSG - Mechatronics:- In the DQ250, the mechatronics is housed inside the gearbox, surrounded by DSG oil, whereas in the DQ200, it is flanged onto the gearbox. This means that, in the DQ200, the mechatronics has a separate oil circuit, independent of the gearbox oil circuit. The mechatronics comprises of an electronic control unit and an electrohydraulic control unit. The electronic unit is where the learning or the adaptation regarding the position of the clutches, positions of the gear actuators and the pressure characteristics - get developed or imprinted due to a particular driving style over a period of time. Now you know the source of the DSG's "intelligence"! The salient features of this autonomous, compact unit are:-

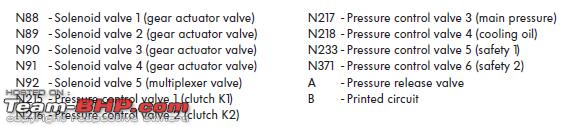

For the DQ250, the electro-hydraulic control unit houses all the solenoid valves, pressure control valves and hydraulic selectors alongwith the multiplexer, as shown in the below diagram:-   Since this gearbox has the common lubrication circuit for all units, the oil has the task of lubricating/ cooling the clutch plates, gear wheels, shafts and also actuation of the plates and plungers. Here is the oil circuit diagram for the DQ250:-  Even though the above diagram is self-explanatory, however just to give it a perspective - it starts with the oil pump drawing oil from the sump and and supplying it to the pressure valve. The pressure generated by this valve is then used to actuate the multi-plate clutches and final selection of the gears. Since the DQ250 has multiple clutch plates, the heat produced by the mechanical friction of the plates is cooled by a separate cooling oil circuit, as shown in the below diagram:-  The pressure control valve increases/decreases the oil pressure at the slide valve depending upon the temperature generated. Point to note, however obviously, that the DQ200 does not have this separate clutch cooling oil circuit due to absence of the multiple plates. Now coming to the biggest misconception for the DQ200 - as can be seen in the below diagram, there are not 1 but 2 separate oil circuits:-  As is evident from the above, the 2 circuits run on independent oil supplies. When it comes to the various sensors for the mechatronics's electronic control unit, all actions are analysed and directed from this unit. Below diagram showing the sensor locations:-  The sensor G182 is the only sensor located outside of the mechatronic unit. In the event of signal failure due to this sender, the control unit uses he engine speed signal from the ECU. The input senders G632 and G612 help in calculating the speed of drive shafts 1 and 2. In the event of signal failure of G632, the vehicle can be driven only in gears 2,4,6 and R. And for failure of G612 signal failure, the vehicle can be driven only in gears 1,3,5, and 7. The temperature sensor G510 is used to check the mechatronic unit's temperature. In the event of signal failure, the control unit uses an interally available substitute valve. The hydraulic pressure sender G270 is used to control the motor for the hydraulic pump. In the event of hydraulic pressure reaching approx 60 bar, the motor is shut off according to the signal and switched on again at 40 bar pressure. For the gear selector movement sensors 1 to 4, G487 to G490 - on combination with the solenoids, they generate a signal from which the control unit recognises the precise position of the gear selectors. In the event of a signal failure, the control unit is unable to recognise whether or not a gear is changed and the failed gearbox path is shut off in this case. Now for the electro-hydraulic unit of the DQ200:-  The hydraulic pump pushes the oil through the filter towards the pressure limiting valve, the accumulator and the hydraulic pressure sender. The pressure accumulator provides the system with oil pressure when the hydraulic pump is switched off. As for the valve setup, this comprises of the clutch actuator solenoid valves (N435, N439), gear train half pressure control valves (N436, N440), gear selector solenoid valves (N433, N434, N437,N438). In the event of one of the solenoid valve failing, the corresponding gear train half is shut off. Now moving to another important section for the gearbox, related to shifting the gears.. As in the case of conventional gearboxes, the gears are shifted using selector forks. Each fork shifts two gears. The below diagram depicts the housing:-  When changing gears, the forks are moved via gear selectors integrated into the mechatronic unit. The way it works is that the gear selector piston is connected to the selector fork. To change gears, oil pressure is applied to the gear selector piston, thereby moving it. When it moves, it also moves the selector fork and the sliding sleeve. The sliding sleeve then actuates the synchronising hub and the right gear is engaged, as shown in the below setup:-  To end this section, here is a sample video showing an equivalent of an "Unboxing" DQ200 gearbox:- Back to index Last edited by JoshMachine : 10th January 2019 at 14:45. |

| |  (60)

Thanks (60)

Thanks

|

| The following 60 BHPians Thank JoshMachine for this useful post: | Added_flavor, akash_v12, AlphaKilo, amit_mechengg, anshumandun, arbaz906, Arjan, ashking101, audioholic, balenoed_, bhpfaninblr, CarLoverJosh, cs_rajesh, deepfusion, Driver 33, Evyas, Gannu_1, GForceEnjoyer, GTO, hemanth.anand, jailbird_fynix, Jeevith, jojijacob, Joxster, Leem, Leoshashi, LionX, MohanRajP, MotorDev, Mukund, myavu, N33raj, Omkar, OnePM, PraNeel, R2D2, Rajeevraj, roby_dk, rphukan, Rudra Sen, sagwal, Sankar, Santoshbhat, shaheenazk, Shrix458, Shubhendra, Simat, SnS_12, sridhar-v, Sutripta, Taha Mir, tchsvy, Thad E Ginathom, The Rationalist, The_Outsider!, Turbanator, Varun_HexaGuy, WasavaTyres, yesyeswe, Yugansh |

| | #5 |

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox THE OWNERSHIPS So, by now I hope that you would have got a very good understanding of how the various valves, sensors, actuators and the gear assembly come together to produce that beautiful motion when engaged correctly! After having understood the fundamentals (at at certain places, something more than that!), this section will now attempt to capture - at one place - various ownership threads posted on TBHP, so that we can browse through them and compare, learn and understand the various owner perspectives. I know by looking at the list here, some of you may argue that we could just search up the various forums with specific keywords etc. and not required to have a list as such but my view is to have everything sorted out and assembled together, so that we can navigate easily and even add to the list here in the future so that this evolves over time immemorial! While browsing through some of the reports, I was amazed to find so many nuggets of valuable info related to DSG ownerships - obviously both good and bad experiences. As I mentioned in my opening post, the emotions have ranged from extreme delight to shock! These ownership links are arranged in no particular order (either in buying timelines or duration of ownership as such). However, what I have attempted is to cover both the categories of DSG ownerships - "Initial" ownership reports and the really "Long-Term" ownership reports by taking into consideration Skoda and VW car owners. This list may not be 100% complete to start with (have 75 ownership reports listed for now), and it is possible that I may have not been able to include some ownership references. However, as I mentioned earlier, will keep on updating this thread and would also request folks to let me know of instances which need to be included in this DSG story. Looking at the Skoda list firstly. Superb owners:- Swanand Inamdar - report | ivar1951 - report | sahil - report | Hayek - report | holysmoke - report | BoringProf - report | Octavia owners:- Joethomasv - report | Sandeepsarma - report | Starrysky - report | abhinav.gupta88 - report | karvel - report | nikhilb2008 (vRS) - report | sivadas (vRS) - report | imidnightmare - report | sawnilrules - report | suhaas307 - report | adi_petrolhead - report | Laura owners:- .anshuman - report | Vignesh.cv - report | newtonMeter - report | luky_13 - report | goutham_r - report | .cArMaNiA - report | amit2kin - report | danc - report | razor4077 - report | seacat - report | hvishwanathan - report | | Insane Devil - report | kiranjoshy - report | lamborghini - report | nitinbose - report | akki_5 - report | ACM - report | deepakvrao - report | Karoq owners:- Starrysky - report | Rapid owners:- Laddz1121 - report | MadAbtCars - report | charansuki - report | rohanjf - report | shubhu3112 - report | And this is followed by the VW list. Passat owners:- fordfreak - report | kimianks - report | ev06 - report | Jetta owners:- Iliketurtles - report | Amarendranath - report | Graaja - report | sunsbhp - report | abhilashgp - report | aseem - report | ayedongivadam - report | Aurum - report | althaaf - report | akhilesh51 - report | cls_55_AMG - report | Vento owners:- Execve - report | rejeen - report | Rajeevraj - report | amitg79 - report | Joshmachine (yours truly  ) - report | ) - report | Polo owners:- frankmehta - report | diffsoft - report | Nevgin - report | graaja - report | chase_nt - report | Santoshbhat (Polo GTI) - report | abhilashnanda (Polo GTI) - report | hemanth.anand - report | robimahanta - report |nishcal316 - report | pilot77in - report | GTPower - report | prateekswarup - report | suhaas307 - report | Back to index Last edited by JoshMachine : 4th January 2019 at 14:05. |

| |  (54)

Thanks (54)

Thanks

|

| The following 54 BHPians Thank JoshMachine for this useful post: | Added_flavor, akash_v12, AlphaKilo, anshumandun, arbaz906, Arjan, asingh1977, audioholic, balenoed_, CarLoverJosh, DrANTO, Drbhavesh, Driver 33, Evyas, francis_vaz, Gannu_1, GForceEnjoyer, GTO, hemanth.anand, InControl, jailbird_fynix, Jeevith, Joxster, KA19Rao, kunaldhami, Leoshashi, manjubp, Manoj2268, mishraak, MotorDev, myavu, N33raj, NiInJa, PrasunBannerjee, psispace, R2D2, rainmaster, roby_dk, Sankar, Santoshbhat, Shrix458, Shubhendra, SILVER-ARROW, SilverSmoke, SnS_12, somspaple, Sutripta, tchsvy, TDI_Power, The Rationalist, The_Outsider!, Varun_HexaGuy, WasavaTyres, Yugansh |

| | #6 | |

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox My 2 cents on the DSG ownership and experience When I put up the ownership report of my Vento last year (the car had close to 35k km on the odo), I had outlined some initial experiences of the DSG at this post. As of today, when the odo reads approx 60k km on the Vento, just to give a perspective of my driving patterns and usage based on which I have derived my DSG experiences, here is a break-up of the same:-

So, looking back in hindsight, I feel that I have been involved in a reasonable mix of highway and city driving scenarios, based on which I have inferred my own experiences of the gearbox behavior. Am glad to reiterate that almost all of the advantages /observations from my ownership post hold true even today. Just re-quoting from the original post herewith:- Quote:

For those who are uninitiated with respect to the DSG world yet, here is a high-level summary view of the various driving modes:-

Back to index Last edited by JoshMachine : 11th January 2019 at 13:52. | |

| |  (45)

Thanks (45)

Thanks

|

| The following 45 BHPians Thank JoshMachine for this useful post: | Added_flavor, akash_v12, AlphaKilo, amit1agrawal, anshumandun, asingh1977, audioholic, CarLoverJosh, DrANTO, Evyas, ganny, GForceEnjoyer, graaja, GTO, hemanth.anand, hillsnrains, InControl, jailbird_fynix, Jeevith, Joxster, Leoshashi, manjubp, MotorDev, myavu, N33raj, nalinsaxena23, NiInJa, Omkar, OnePM, R2D2, rbp1988, redcruiser, roby_dk, sagwal, Sankar, Shrix458, SILVER-ARROW, Simat, SnS_12, Sutripta, tchsvy, Thad E Ginathom, The Rationalist, Varun_HexaGuy, WasavaTyres |

| | #7 | ||

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox The FAILURES The year 2018 coincided with the 15th anniversary of DSG production (as noted in the "The Launch and Initial Success" post above). The origins (and majority of the production) of the DSG is attributed to a German plant located in the town of Kassel. Until the middle of 2018, more than 26 million drivers of Volkswagen Group models have opted for a dual clutch gearbox (mostly 6-speed and 7-speed). That's putting it to approx. 20-22% as DSG-powered vehicles out of the total volume of passenger cars sold by VW Group in the last 15 years or so. When it comes to individual car brands like the Golf, Polo, Passat etc. these percentages are even higher, going upto 40% or even 60% in some cars. In 2018 - the annual production of the Kassel plant was 3.6 million gearboxes and in terms of passenger car sales, VW group sold close to 9.3+ million globally - thus it can be extrapolated that approx. 38% cars were powered by a DSG in 2018 from the Kassel plant (numbers for DSGs produced from other global locations not known). However with such a relatively good success rate for the famous gearbox, VW has been very infamous in its handling of the problems attributed to the same. This section intends to bring out some of the most widely known issues and the most probable root causes for them, along with the solutions suggested / implemented by VW. The basis of the research has comprised studying various forums, VW technical documents, 3rd party analyst reports and talking to service advisors, Master Technicians (from VW), colleagues from the automobile engineering fraternity and our very own TBHP chronicles. Generally speaking, both sets of gearboxes i.e. DQ250 and the DQ200 have had customer complaints across the globe, but the latter has drawn more flak due to the sheer volume of 7-speed DSG-powered cars getting sold (especially in Asia-Pacific region). In no particular order of appearance or severity, listing the various issues/complaints that have surfaced:-

There have been some other complaint categories also but those have been some or the variant of the above. In terms of the geographies affected, here is the list:-

Source: Phoenix Friction Back to index Last edited by Aditya : 15th January 2019 at 10:31. | ||

| |  (57)

Thanks (57)

Thanks

|

| The following 57 BHPians Thank JoshMachine for this useful post: | --gKrish--, akash_v12, audioholic, AYP, benbsb29, CarLoverJosh, DrANTO, eapen, fabia_firstcar, Gannu_1, ganny, GForceEnjoyer, govigov, graaja, GSMINC, GTO, g_sanjib, hemanth.anand, Holyghost, itssmano, jailbird_fynix, Jeppu, Joxster, Leem, manjubp, Manoj2268, Mukund, Muthu25, myavu, N33raj, nalinsaxena23, NiInJa, Nrulz, Omkar, OnePM, PraNeel, R2D2, rbp1988, Sankar, Santoshbhat, shaheenazk, sharktale, Shrix458, Shubhendra, SILVER-ARROW, Simat, smilingakash, sridhar-v, Sutripta, Taha Mir, tchsvy, Thad E Ginathom, treadmark, Turbanator, TurboCruiser, vedirah, WasavaTyres |

| | #8 |

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox REFERENCES Researching a topic as broad and controversial as this one entailed to look up myriad of news reports, scan through annual reports of VW, look up environmental reports, try to understand or rather go back to refreshing some concepts related to chemistry & physics and also talk to few folks related to the industry (colleagues in the automobile fraternity, Master Technicians). Ofcourse, one of the main sources was the service or technical manuals for the gearbox. Few times, Google Translate was also invoked since some materials were Russian or German. Here are some sources and artefacts that I could lay my hands on:-

p.s. The above are only some of the key sources at the top of my mind. There were other news articles which I have browsed but difficult to list all of them here. Back to index Last edited by JoshMachine : 11th January 2019 at 13:52. |

| |  (94)

Thanks (94)

Thanks

|

| The following 94 BHPians Thank JoshMachine for this useful post: | --gKrish--, ACFT, akash_v12, AlokSharma, Ameya_G, amit1agrawal, amit_mechengg, anToNIcHeN, asingh1977, audioholic, Auto freak, avinash_m, avisidhu, bhpfaninblr, Bibendum90949, CarLoverJosh, catchjyoti, Divya Sharan, Dr.Naren, Dr.Vikas, DrANTO, Driver 33, drivingmelody, Evyas, flyingswan, francis_vaz, Gannu_1, GForceEnjoyer, giri2000, graaja, GrammarNazi, greendream, GTO, harikrishnansp, hemanth.anand, Immix, itssmano, jailbird_fynix, jayakumarkp, Joxster, ksameer1234, Leem, mallumowgli, manjubp, mbhaskar, MSAneesh, Mtv, Mukund, Muthu25, myavu, N33raj, Nomad01, Nrulz, Omkar, omranga98, Paradox p100d, porsche_guy, pranavtengshe, prashanthyr, psispace, purohitanuj, R2D2, Rajeevraj, rajvardhanraje, recshenoy, redcruiser, roadie_swift, roby_dk, rocksterraghu, sainyamk95, Sankar, Santoshbhat, shetty_rohan, Shrix458, Shubhendra, SILVER-ARROW, singleton, somspaple, srishiva, Sutripta, tchsvy, Thad E Ginathom, The Rationalist, The_Outsider!, Thyag, TOR, TurboCruiser, Varun_HexaGuy, vedirah, venkyhere, vnabhi, WasavaTyres, yesyeswe, Yugansh |

| | #9 |

| Team-BHP Support  | Re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox Thread moved from the Assembly Line to the Technical Section. Thanks for sharing! |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank GTO for this useful post: | JoshMachine, roby_dk |

| | #10 |

| Distinguished - BHPian  Join Date: Oct 2008 Location: Pune

Posts: 3,257

Thanked: 5,855 Times

| Re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox Painstakingly researched and a delight to read the history, electro-mechanical operations, problems, failures and most importantly customer experience. Thanks for a delightful Saturday morning read. Rated 5 stars.  |

| |  (5)

Thanks (5)

Thanks

|

| The following 5 BHPians Thank R2D2 for this useful post: | harikrishnansp, JoshMachine, roby_dk, sainyamk95, TurboCruiser |

| | #11 |

| BHPian | First of all, let me thank you for this wonderful post! It certainly made my day! Also, BHPians will definitely love it and this article will be most helpful for ownership experience as well as buying experience. Oh man, I had thought DQ250, was trouble free. The sheer number of recall made by VW group is jaw dropping! IMO, mechanical parts have certain efficiency which can not be increased after some limit. However, DSG contains lots of electronics which could have certainly helped to evolve the unit characteristics. In this case, it has gone into another side. I believe, electronics are major culprit here. What could have done from VW side in this issue? Anybody, please share your views. This technology should have been improvised. If VW had provided extended warranty around 10 years or DSG cover at least, it would have been really helpful to prospective buyers. Cheers and happy revving! |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank RedStallion for this useful post: | harikrishnansp, JoshMachine, roby_dk |

| |

| | #12 | |

| Senior - BHPian Join Date: May 2005 Location: Location

Posts: 5,780

Thanked: 9,254 Times

| Re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox So much tech to get power to the wheels... Cons:

Pros:

The fun part is no longer exclusive to DSG/DCT as per Peter Quintus of BMW: "It's more a question of how long has the DCT got to go, How long will it last? The DCT once had two advantages: it was light and its shift speeds were higher. Now, a lot of that shift-time advantage has disappeared as automatics get better and smarter." Andy Palmer of Aston Martin (previously Nissan) says: “Ten years ago, it still looked like the transmission of the future. Now it is starting to look like the transmission of the past. A good conventional automatic gearbox like the ZF is cheaper, which is absurd when you think that the manual gearbox has survived because it is meant to be the less expensive option, but there’s so much technology loaded onto a (DCT) to make it work. It’s heavier as well, which is another disadvantage, but the real issue is the gearchange itself. It’s actually now faster in a (planetary) automatic, because you can control the torque. That means ultimately your 0-100 km/h times are quicker with an auto, which takes away all of the marketing puff for the dual-clutch,” And this is old news, I saw it come up three years ago but still relevant today and in this thread. Reminds me of the decision by Ford to discontinue its DCT in India for torque converter auto in the Ecosport. https://www.autonews.com/article/201...e-favor-in-u-s Src: https://www.drive.com.au/motor-news/...18-gvndyw.html https://www.bmwblog.com/2017/04/21/b...ons-soon-gone/ https://paultan.org/2018/05/16/the-f...-transmission/ I would never ever buy a car with a DSG as my main car, though I have been tempted by some VAG models. I simply cannot live the damascus sword hanging over my head worrying about a ! inside a cogwheel symbol popping up on the dashboard or the thought of would it ever will far away from home. I said the same thing 4 years ago and i live by it, today I drive a 6 speed torque converter equipped diesel, but not a Verna. Quote:

Last edited by Sankar : 12th January 2019 at 10:39. | |

| |  (11)

Thanks (11)

Thanks

|

| The following 11 BHPians Thank Sankar for this useful post: | adimicra, Bibendum90949, Dr.Naren, harikrishnansp, hemanth.anand, JoshMachine, Karthik Chandra, ksameer1234, Mtv, narayans80, Rocketscience |

| | #13 |

| BHPian Join Date: Oct 2017 Location: PUNE

Posts: 79

Thanked: 141 Times

| Re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox Amazing thread!Looks very painstakingly researched and written. Hats-off! This thread deserves a five star rating  This will help any prospective VW group car buyers. Looking at the sheer complexity (or simplicity, depends how you interpret it) of the DSG concept, there are bound to be cases of failure in the future as well. Just hope that these guys continue to offer an option for manual transmission as well in India. The simplicity and robustness of a manual can never be matched (my take here, so opinions can definitely differ)! |

| |  (3)

Thanks (3)

Thanks

|

| The following 3 BHPians Thank AdiSolEn for this useful post: | adimicra, harikrishnansp, JoshMachine |

| | #14 | |||||||||

| Senior - BHPian Join Date: Jan 2013 Location: Pune

Posts: 1,251

Thanked: 6,177 Times

| Re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

| |||||||||

| |  (4)

Thanks (4)

Thanks

|

| The following 4 BHPians Thank JoshMachine for this useful post: | RedStallion, roby_dk, Simat, Thad E Ginathom |

| | #15 | |

| Senior - BHPian Join Date: Jul 2009 Location: Calcutta

Posts: 4,665

Thanked: 6,233 Times

| Re: DSG, demystified! All you need to know about VW's Direct-Shift Gearbox @JM- great post! Does the DSG gearbox oil come in contact with ambient air? Quote:

The ZF 9 speed, like the DSG, is building up a nice unreliability reputation! Regards Sutripta | |

| |  (2)

Thanks (2)

Thanks

|

| The following 2 BHPians Thank Sutripta for this useful post: | roby_dk, Sankar |

|