|

Quote:

Originally Posted by discoverwild  So, in simple english, you plan to go swimming without getting your feet wet.  |

he he, That would be fun -- pure unadulterated adrenalin rush for me.

But on an equally serious note, where ever you have to push hard (assume trying to climb a rock and front wheel not moving easily and you need to throttle up) then you will have higher chances of axle wrap. Quote:

Originally Posted by svsantosh  ... This work deserves a seperate thread "The Axle Wrap (Avoidance) Project".

Is the possibility of Axle Wrap HIGH in SPOA than SPUA???

(EDIT)

Answer - 4X4wire site says "Yes" |

I have to get this done because of SPoA + composite springs. These springs are GREAT but by their nature they flex easily (doesn't mean that are spongy -- can't explain it any better) hence chances of axle wrap are more.

This is part of the whole SPoA project, hence have posted it here. It can be spun off into a separate thread later if required. Quote:

Originally Posted by Samurai  What is the downside to installing traction bar? Definitely it limits some movement. |

This is a trade off you "have to" make while going SPoA -- it would/could limit 'some' articulation.

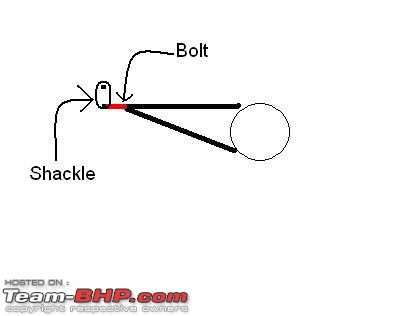

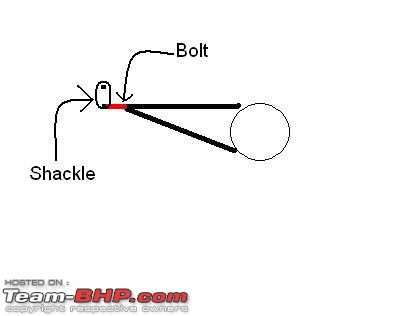

BUT one of the ends of the traction bar has a threaded bolt that takes care of movement not getting restricted during the articulation process. What can also be done is to have Jhonny Joints (Rose/Thiem Joints) so that there is enough of flex at the joints. However I will be getting only regular bushing done + threaded bolt at one end.

Here is an illustration that one of the zukiworld members shared with me on the design concept to be kept in mind

Here are some of the points to consider in a 'triangulated traction bar':

- The length of the traction bar should be of similar length as that of the rear propeller shaft

- The lower bar should be at same angle/parallel to the rear propeller shaft

- The upper bar should be 'as' parallel to the ground as possible

Cheers,

Last edited by khan_sultan : 19th July 2009 at 17:04.

Reason: added some details

|