Quote:

Originally Posted by pranavt  Loving the engine note too. Sounds more refined but throaty. Don't believe in seat-of-the-pants-dyno readings and will not post about the theoretical million horsepower increase or differences in throttle response. Now time to push this car to the next level. All will be known in a few months  |

And exactly 3 months and a day later, it's pretty much done. I've never been much of a sucker for outright power. No 600 bhp straight-line monsters for me. Being nimble around corners and better throttle response is more important than a 300 kph rocket. I was stuck with a dilemma after the basic intake/exhaust mods were done. Going the FI way was an option but I did not have the motivation to do it for whatever reason. Too much power very suddenly. A huge thanks to Viper/Jignesh-bhai for telling me about ITBs. 4 months ago, I was an absolute newb, and didn't know what a throttle body was, where it was located or what it did. Big thank-yous go out to Jitu-bhai (Ford ROCAM), Jignesh-bhai (Viper) and Doomsday for answering whatever questions I had. I owe you guys.

Anyways, since then, I've been reading everything I can get my hands on. First read about ECUs and the potential of remaps on Honda ECUs. I had to do it. Then while thinking about what to do next, I checked out a few Honda fansites/forums and read about the modding scene outside our country. Read more about ITBs and what they offered. Decided to try it myself after hearing that there were no more than a handful ITB'd cars in India. So this was to be a complete DIY job. More fun in getting your hands dirty and learning a few things, right?

The last 3 months have been 4 am sleep nights (facebook people will know

) with gallons of coffee consumed, and real blood and sweat being spent trying to get everything in order. I am a computer person, and I had absolutely no knowledge of mechanicals or mechanics-related jargon, so conversing with the labourers and CNC operators was always a difficult task. Somehow got the concept into these people's brains and got the work done. The most priceless part of these conversations was something that went like this:

Him: Ye kya car ke liye part hai? (Is this part for a car)

Me: Haan (Yes)

Him: Matlab custom design hai, aapka khud ka personal project? (Is it a custom design for your personal project?)

Me: Haan (Yes)

Him: Average badhane ke liye hai kya? (To increase the mileage of your car?)

Me:

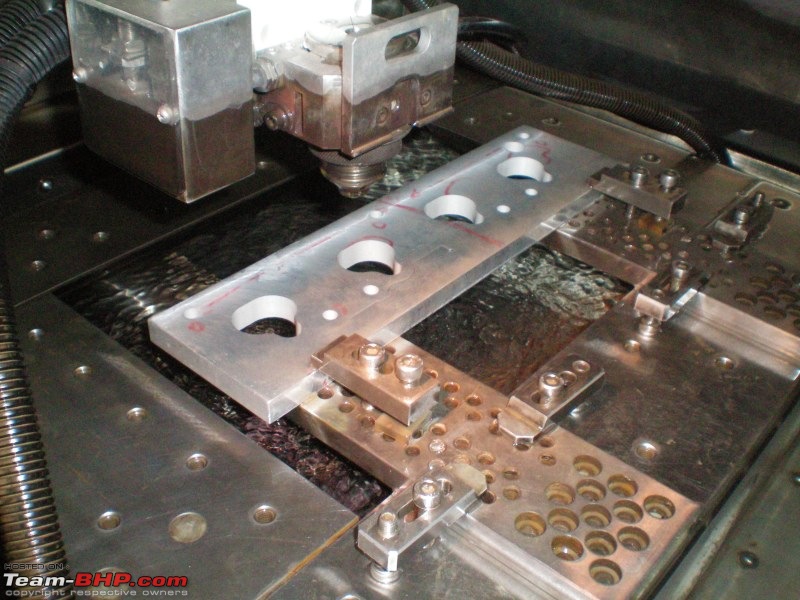

The flange is a CNC wirecut prototype, first designed by me in 3D, then converted to 2D and finally cut in a CNC wirecut machine. The intake runners have been cut at a specific degree to mate with the ITBs. The FPR has been converted to an adjustable type, with a fuel pressure gauge from Aeromotive. The ECU is a Honda P28 chipped and modified to accept 28 pin EPROM chips which store the complete fuel/ignition maps, plus various features like launch control, support for ITBs with full Alpha-N mapping or a mixture of MAP and TPS with capability to set crossover values, automatic AC cutoff after specific RPMs or TPS values and lots more. The tuning software being used currently is CROME, and I will be moving on to eCtune once I have a few more monies. Datalogging is done from the ECU using a USB cable and I can monitor each and every sensor in the car, and combined with the wideband readings, get complete graphs and tables of various values at specific RPMs or AFR values.

The ITBs are from a Honda CBR954RR, 42mm butterfly diameter. The length of the complete intake system has been calculated using mathematical formulas based on the powerband where I need my power. The injectors are stock for now since they will do the job based on my calculations. Velocity stacks are coming in tomorrow.

To give an idea of the scale of the DIY job, almost all the fittings, the flange, the runners, the fuelling setup, the ECU chipping, the ECU mapping (with a wideband sensor) have been/will be done by me. Possibly the third aftermarket ITB setup in India I believe, and the first/second in Mumbai, based on what I've heard.

Finally, a video taken earlier today. The first crankstart with the ITBs.

The car started on first crank and sounded amazing. A camera cannot capture the sound of ITBs properly. Haven't driven it yet because a clumsy mistake by the mechanic broke my radiator pipe and the ITBs are not yet mounted tightly to the runners because of misfitting clips/couplers. A scary mistake which almost resulted in the car going up in flames after the ITBs were thrown off the runners and some fuel was sprayed outside the engine lol. Should be done tomorrow. The car is currently running very rich (AFR: ~9.5) because no vacuum or sensor connections were done and fuel pressure was not adjusted, nor was the ECU remapped. More updates in the coming days with in-progress pics of various components and me.

Mods: Can you add "Now with ITBs!!" at the end of the thread title please?

Is exactly what I am running on my OHC too. Just picked up brand new alloys (14") and tubeless Good year tyres (195/60).heres a pic of my OHC baby!

Is exactly what I am running on my OHC too. Just picked up brand new alloys (14") and tubeless Good year tyres (195/60).heres a pic of my OHC baby!

When do i get a test drive?

When do i get a test drive?

Not to forget, Lineas and Puntos!

Not to forget, Lineas and Puntos!