News

Video: See-through V8 shows how an engine works

To get the pistons moving, the crank is powered by an electric motor.

The SmarterEveryDay Youtube channel recently put up a video showcasing a perfectly see-through replica of a V8 engine.

The see-through V8 engine belongs to Brian King and is based on a 5.3-litre LS Block from General Motors. As per reports, King bought an old broken-down V8, stripped it off all the metal and rebuilt it using plexiglass.

The replica V8 even comes with working pistons, a crankshaft, lifters, springs, and valves, and also has a functioning oil pump. However, being a demonstrator, it doesn't get real spark plugs but is instead replaced with tiny lights, which light up during the engine's power stroke.

Also, to get the pistons moving, the crank is powered by an electric motor. This movement really helps to understand the workings of the engine. It also showcases the true speed of a running engine, the firing order and balancing.

Source: SmarterEveryDay/YouTube

- Tags:

- Indian

- V8

- International

News

My Mustang clocks 42000km: Thoughts on daily usability, build & more

Tyres and brakes don’t last long if you drive regularly on the highway

BHPian Thegreyghost006 recently shared this with other enthusiasts.

Touched 42 thousand kilometres in my Ford Mustang.

Points I’d like to share:

- Five and a half years old and still no rattle in the interior (I think the materials might not be exotic but it sure is built to last).

- Tyres and brakes don’t last long if you drive regularly on the highway - 5 to 6 thousand kilometres maximum.

- It’s pretty usable apart from the fact the turning radius affects its usability more than its ground clearance (U-turns, tight space parking).

- Availability of XP95 and Power 95 have been a boon and one does not require fuel additives anymore.

Vellore has only one Mustang.

I am uploading a few pictures, I will share some more in the near future and also come up with my experience so far with an in dept review:

Check out BHPian comments for more insights and information.

- Tags:

- Indian

- Ford Mustang

- V8

- Petrol

- muscle cars

News

Mercedes-AMG to bring back V8 to C63 & E63 models

The 8-cylinder engine will receive updates to help it meet the stringent Euro 7 emission standards.

Mercedes-Benz recently introduced the latest iteration of the AMG C63 with a hybridized 4-cylinder turbo-petrol engine. While the upcoming AMG E63 is expected to feature an in-line 6-cylinder plug-in hybrid powertrain. Now though, it has been reported that Mercedes-AMG is planning to bring back the V8 engine to both the C63 and E63 models.

As per media reports, the M177 4.0-litre twin-turbocharged V8 engine could be re-introduced on the range-topping C and E-Class models in 2026. The 8-cylinder engine will receive updates to help it meet the stringent Euro 7 emission standards. The V8 currently powers the brand's AMG GT63 S E Performance and the AMG S63, producing 831 BHP and 791 BHP, respectively. Both range-topping AMG models also come with a hybrid setup.

The report also states that both the C and E-Class models will undergo minor bodywork changes as well to accommodate the bigger engine, PHEV battery, electric motor and all other auxiliary equipment. The AMG versions of both the C and E-Class are expected to remain in production well into the next decade.

Source: Car&Driver

- Tags:

- Indian

- AMG

- V8

- International

News

Toyota & Yamaha develop 444 BHP hydrogen-powered V8 engine

The V8 is based on the engine powering the Lexus RC F Coupe.

Toyota & Yamaha are reported to be working together to develop a new 5.0-litre naturally-aspirated V8 engine that runs exclusively on hydrogen. The new engine is said to be part of the collaboration between Toyota, Yamaha, Mazda, Subaru & Kawasaki to continue developing IC engine technology while meeting emission targets.

The 5.0-litre naturally-aspirated V8 is based on the engine powering the Lexus RC F Coupe. While the engine block itself isn't new, it does feature modifications to the inlet manifolds, heads, inlet & other components, allowing it to run exclusively on hydrogen. The engine also comes with a top-mounted 8-to-1 exhaust manifold, which Yamaha claims, creates a very distinctive sound.

Yamaha states that the hydrogen-powered V8 engine produces 444 BHP @ 6,800 rpm and 540 Nm @ 3,600 rpm.

Both companies, though, haven't revealed whether or not the hydrogen-powered V8 will debut on any production car. However, Toyota is committed to the concept since it did run a hydrogen-powered Corolla in Japan's Super Taikyu race series last year.

- Tags:

- Indian

- Yamaha

- V8

- International

News

USA: Mercedes to suspend sales of almost all V8 cars in 2022

Sales of as many as 17 models powered by the brand's 4.0-litre twin-turbo V8 engine will be suspended.

Mercedes-Benz USA is said to be suspending the sales of almost every V8-powered model in its line-up for 2022.

According to a media report, sales of as many as 17 models powered by the brand's 4.0-litre twin-turbo V8 engine will be suspended. These include 13 AMG 63 models, 3 regular Benz 550 and 580 trims and one Maybach trim as well.

Reports suggest that the reason for the suspension in sales is said to be because of a number of factors, including but not limited to supply chain issues in the US market.

It further mentions that customers who have already ordered the MY2022 versions of the affected models will also most likely face cancellation of their vehicle booking.

Mercedes-Benz dealers in the USA are said to have confirmed the update, although the carmaker is yet to make an official announcement regarding the same.

Source: Jalopnik

- Tags:

- Indian

- V8

- International

News

Building a 1:3 scale model of a V8 engine

It was made by a German company called Franzis and they do quite an interesting range of various engines.

BHPian Jeroen recently shared this with other enthusiasts.

First of all, I don’t name my engines, (or cars for that matter). But when showing this to my wife, I was explaining that it was a V8. Originally found in the Good Ol’ US of A and many other (muscle) cars. She told me this was Betty. So there we are, meet Betty the formidable V8 Folks!

Those of you interested in scale model (building) are well served here on Team-BHP. We have several outstanding threads where members show their models. From tanks to cars, to plane and boats and anything in between.

I have started building little engines from metal, all home made on my lathe and mini mill. I recently completed a very simple two Stroke Engine, who was named Debbie by her designer. So now we have a Debbie and a Betty in the family it seems.

I have been looking at these model engine kits for many years. I am not sure how easy they are to procure in India. But here in Europe, a well stocked model build shop is likely to have several in stock. The other day, an ad for a 1:3 scale V8 popped up in my Facebook feed.

It was made by a German company called Franzis and they do quite an interesting range of various engines, have a look.

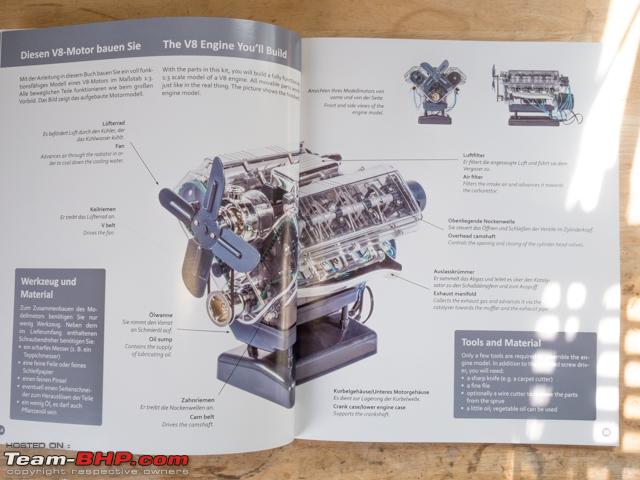

I was interested in the V8 though, going by the ad it featured:

- over 250 parts

- extensive manual

- original V8 sound

- Simulated Spark

- Functional model

- 1:3 scale

Build your own legendary V8 engine and experience what is behind the technology.

I do own a real 4.0L, 400BHP, turbo charged V8. Would be great to see what is inside a typical V8!

So I decided to have a go at it. I ordered it, it arrived about a week ago. Last weekend, I spent about 5-6 hours in total putting it together. Which is saying something on the level of expertise required.

I used to build a lot of airplane models in my teens. I was pretty good at it too. This model does not require any previous model building skills.

This is what the box looked like:

Opening it up:

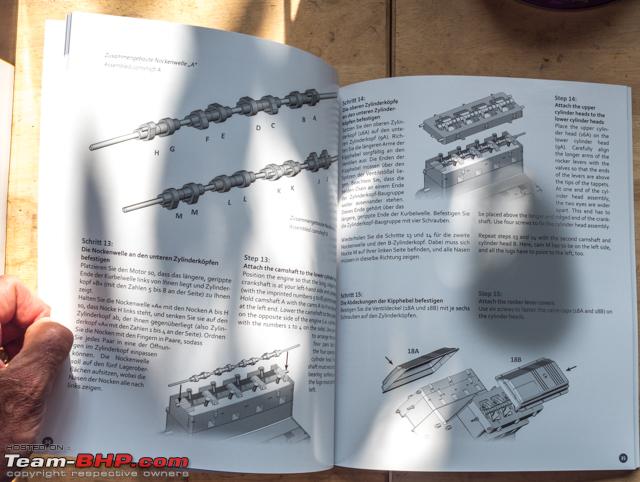

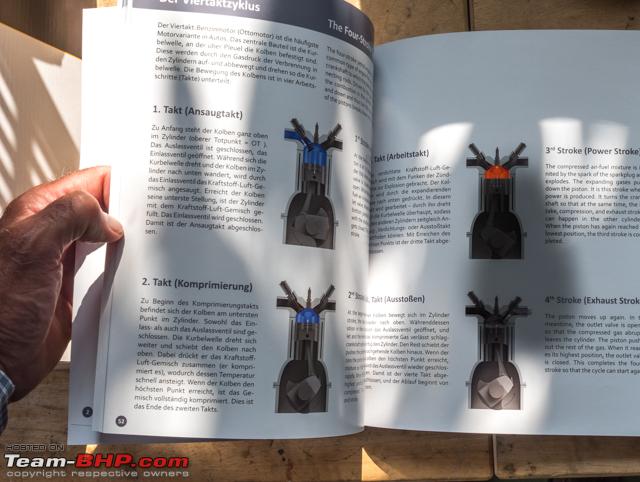

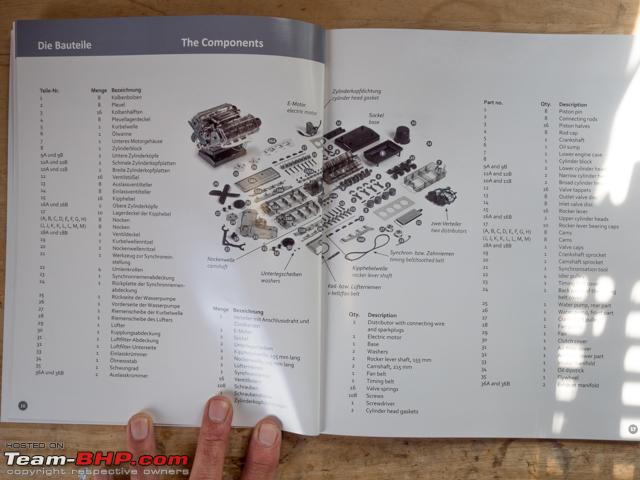

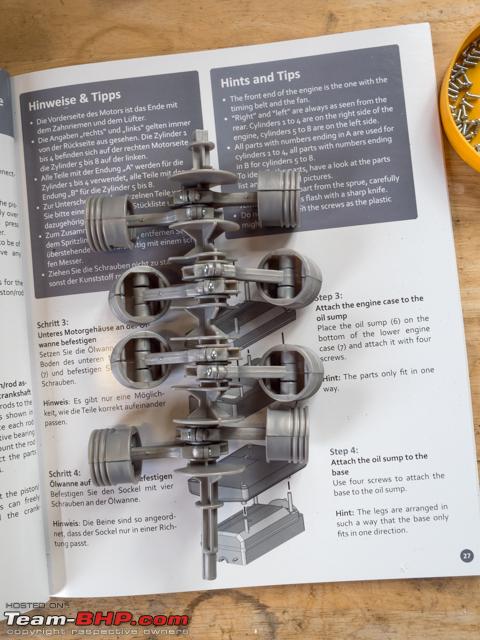

It has a very extensive manual. 72 pages. Not only does it describe, in detail with excellent drawing how to build the model, it also has a wealth of other information on the V8.

It has stories about the development of the V8, cars that used the V8 (AC Cobra, BMW M3) and lots of colour photographs to go with it.

All unpacked and ready for assembly:

This is what the real McCoy looks like:

This is what my 1:3 V8 with simulated spark and original V8 sound will look like!

It has some very good material in the manual. Good in the sense that it helps you find parts during the build. But also it provides you with all the appropriate names for all parts! The complete manual is written in German (on the left) and English (on the right). I was happy to see that the manufacturer actually went through the trouble of providing a decent English translation.

Also shows you the real BMW M3 V8 taken to bits in a similar fashion:

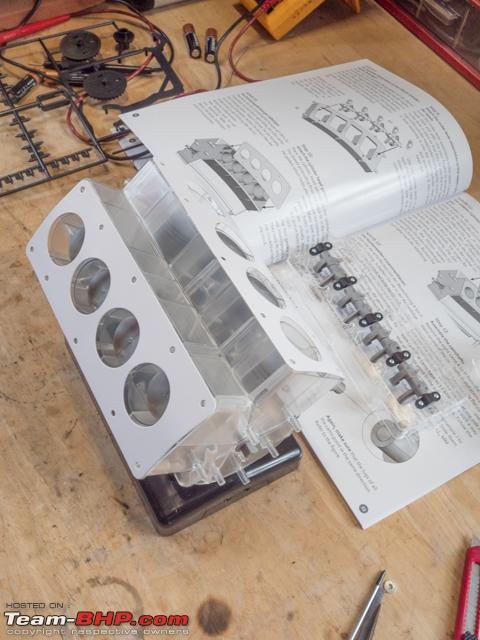

So finding the parts is very straight forward. No glueing is required. Just cut the parts of the frames, remove any excess plastic.

First parts made, 8 pistons with their piston pins and connecting rods:

Next step is fitting them to the crankshaft, one at the time, each with its own bearing cap.

Done!!

The fit of the various parts is not that great, but it is sufficient for the purpose of this kit. Once assembled, it has a small battery driven e-motor so you can see it turn. So all fittings and clearances are very ample. Just so nothing gets stuck.

Here’s the thing with building a V8. You are going to be handling the same parts a lot. There are 8 pistons, 8 connecting rods, 8 inlet valves, 8 outlet valves, 16 valve springs, 16 rockers etc. etc.

It is one of the reason when it comes to metal model building, I prefer a single cylinder engine. So much easier. If you want to see somebody building a real working metal V8 have a look here on my Dutch Modelbuild forum. All in Dutch, just look at the images. The difference between this kind of model building and this kit is huge, of course!

We continue the build by attaching the engine case to the sump. No glue is used on this model. It all clicks together or is held together by tiny screws.

Next, the piston and crankshaft assembly is lowered into the cylinder block:

Another way of illustrating the difference between “plastic Betty” and "metal Debbie”.

The piston-cylinder clearance of Betty is several millimeters.

The piston-cylinder clearance of Debbie is less than 0.03mm. Less than the accuracy of my lathe. Took many, many, many, many hours of honing the cylinder wall to get that sort of precision.

Already beginning to look like an engine, our Betty is:

Next, it was time for the valves to be inserted into the cylinder heads:

All the valve springs were provided on these little metal rods. Very convenient and handy. The rods themselves will be used later for the camshafts!

A valves assembly consists of the tappet, the spring and the valve. The exhaust valves are noticeably bigger then the inlet valves.

With 8 outlet valves assemblies and 8 inlet valves assemblies ready in parts, you insert them in the respective hole of the cylinder head and use your fingers to squeeze the valve onto the tappet.

Repeat 15 more times:

Here you can see what the inlet and outlet valves look like once mounted:

Onto the rocker levers and the rocker shafts:

Each rocker lever assembly fits into its own upper cylinder head. You do need to be careful. Some parts are interchangeable, e.g. pistons. Some parts have left / right orientation and can only be used in one specific location. But all the parts are clearly numbers in the frame and also on the part itself. So when relevant, each part will have an A or B added to it, meaning which side (bank) of the engine it is meant for.

Two cylinder head gaskets are provided. They are not interchangeable either, so make sure you fit the right one to the right cylinder block!!

Continue reading more on the build and BHPian comments for more insights and information.

- Tags:

- Indian

- Scale Models

- Build

- V8

News

Bentley's 6.75-litre V8 engine is now 60-years old

Bentley's V8 engine is now 60-years old and is said to be the world's longest-serving V8 in production. 35,898 engines have been produced since 1959.

The engine made its debut in the 1959 Bentley S2 and had a cubic capacity of 6.2-litres. Over the decades every part of the engine has been re-engineered, but Bentley claims that the basic principles and dimensions that have defined the engine are still the same. The engine size has now gone up to 6.75-litres. In the past, the engine has powered cars like the Mulsanne Turbo and the Brooklands V8.

The original engine was designed and built in 18 months, and it was lighter than the six-cylinder engine it replaced. Today, in the Mulsanne Speed, it produces 530 BHP and 1,100 Nm of torque.

- Tags:

- Indian

- Bentley

- V8

- International

News

Mopar unveils 986 BHP ‘Hellephant’ engine; pre-orders begin

To commemorate the HEMI Day (26 April), Mopar has opened pre-orders for the 986 BHP ‘Hellephant’ engine and kit via cratehemi.com website. The 7.0-liter V8 supercharged engine was announced during SEMA 2018 and is priced at US$ 29,995, excluding installation and taxes.

The engine consists of an all-aluminium block with forged aluminium pistons, steel connecting rods, forged steel crank and a nodular iron camshaft. The bore and stroke is and 104.775 mm and 101.6 mm respectively. The compression ratio is set at 9.5:1. It has a maximum rpm of 6,200 and is rated at 986 BHP and 1288 Nm of torque.

Apart from the engine, Mopar will also sell an engine kit for US$ 2,265 which includes the Powertrain Control Module (PCM), the throttle pedal, power distribution center, ground jumper, oxygen sensors, charge air temperature sensors, fuel pump control module, engine wiring harness, chassis harness, and CAN bus interface device. This kit will allow engine swaps for older cars.

HEMI Day is celebrated in recognition of the 426 HEMI engine (426 cu. inch), which debuted over 50 years ago. The Hellephant name pays tribute to the 426 HEMI that was nicknamed the Elephant.

- Tags:

- Indian

- International

- Mopar

- V8